Novel anti-rotation rolling wheel ascending and descending tappet

A roller lifting and anti-rotation technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of high production costs, wear of anti-rotation devices, complex processing procedures, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

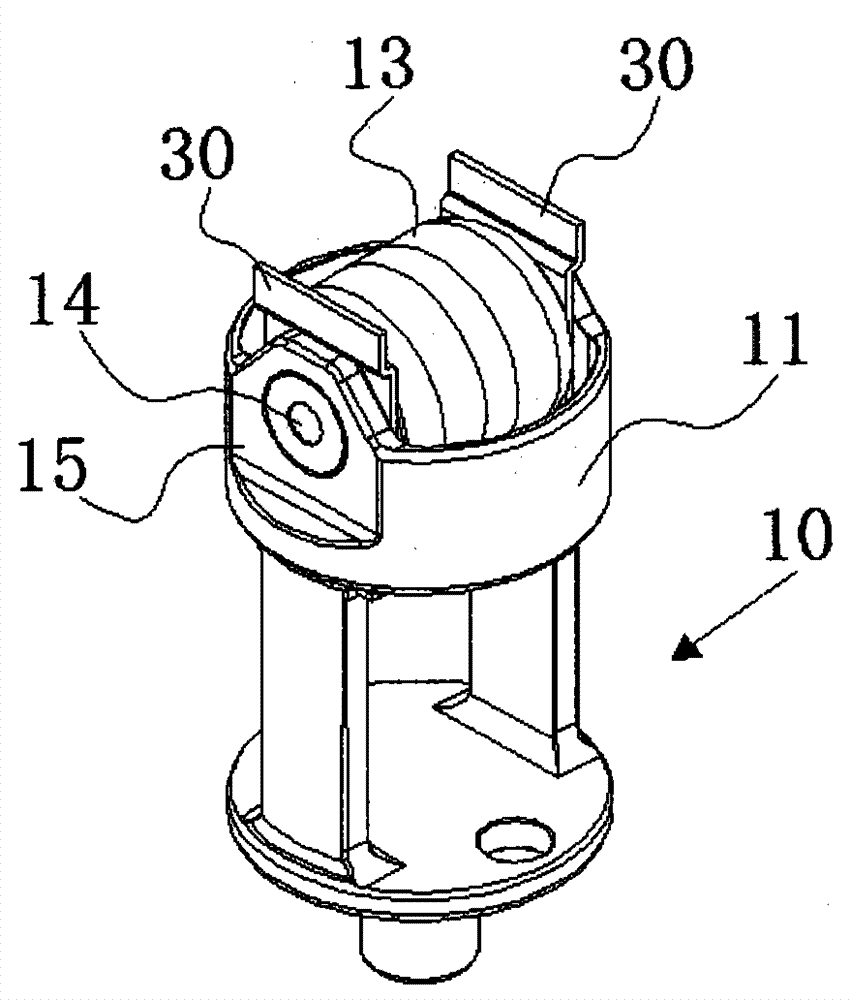

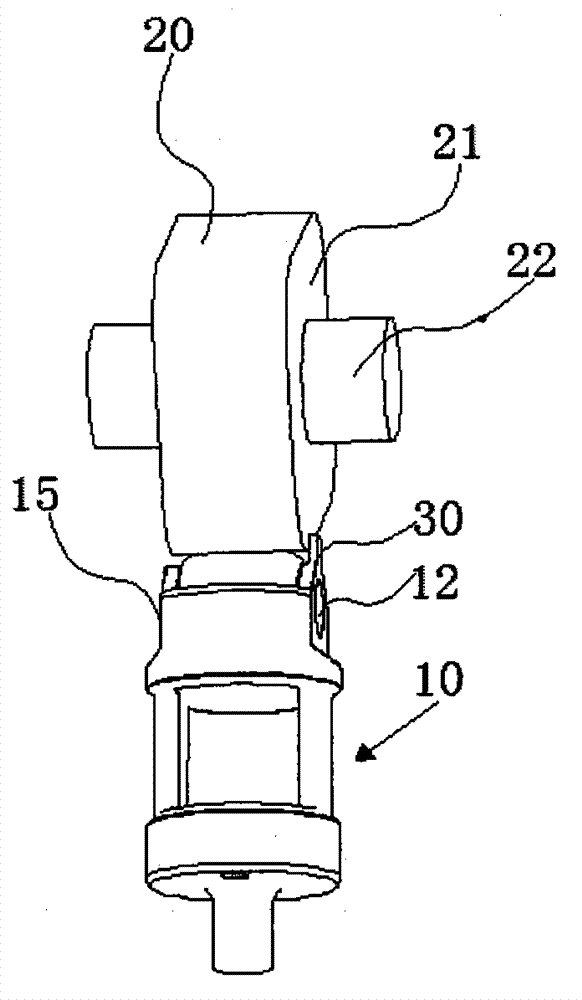

[0029] Please keep reading image 3 As shown, as the second embodiment of the present invention, the anti-rotation card 30 of the present invention can also be an ear plate provided on the platform 15 of the housing 11, and the ear plate is formed by the housing 11 on the side of the cam 20. The end faces the end plate extending in the direction of the cam 20, and the distance between the highest point of the lug plate near the side of the cam 20 and the center line of the pin hole 14 is greater than the radius of the roller 13, wherein the lug plate can be integrally formed with the platform, It can also be formed by welding a flat plate on the platform of the shell 11. That is, during the movement, since the relative position of the cam 20 does not change, and once the tappet 10 rotates reversely, causing the relative position of the roller 13 and the cam 20 to change, the end face of the cam 20 will exert a force on the lug plate beyond the roller. On the end face on the 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com