Surface enhanced Raman spectroscopy (SERS) sensing substrate and manufacturing method thereof

A surface-enhanced Raman and substrate technology, applied in Raman scattering, material excitation analysis, etc., can solve problems such as expensive and limited development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

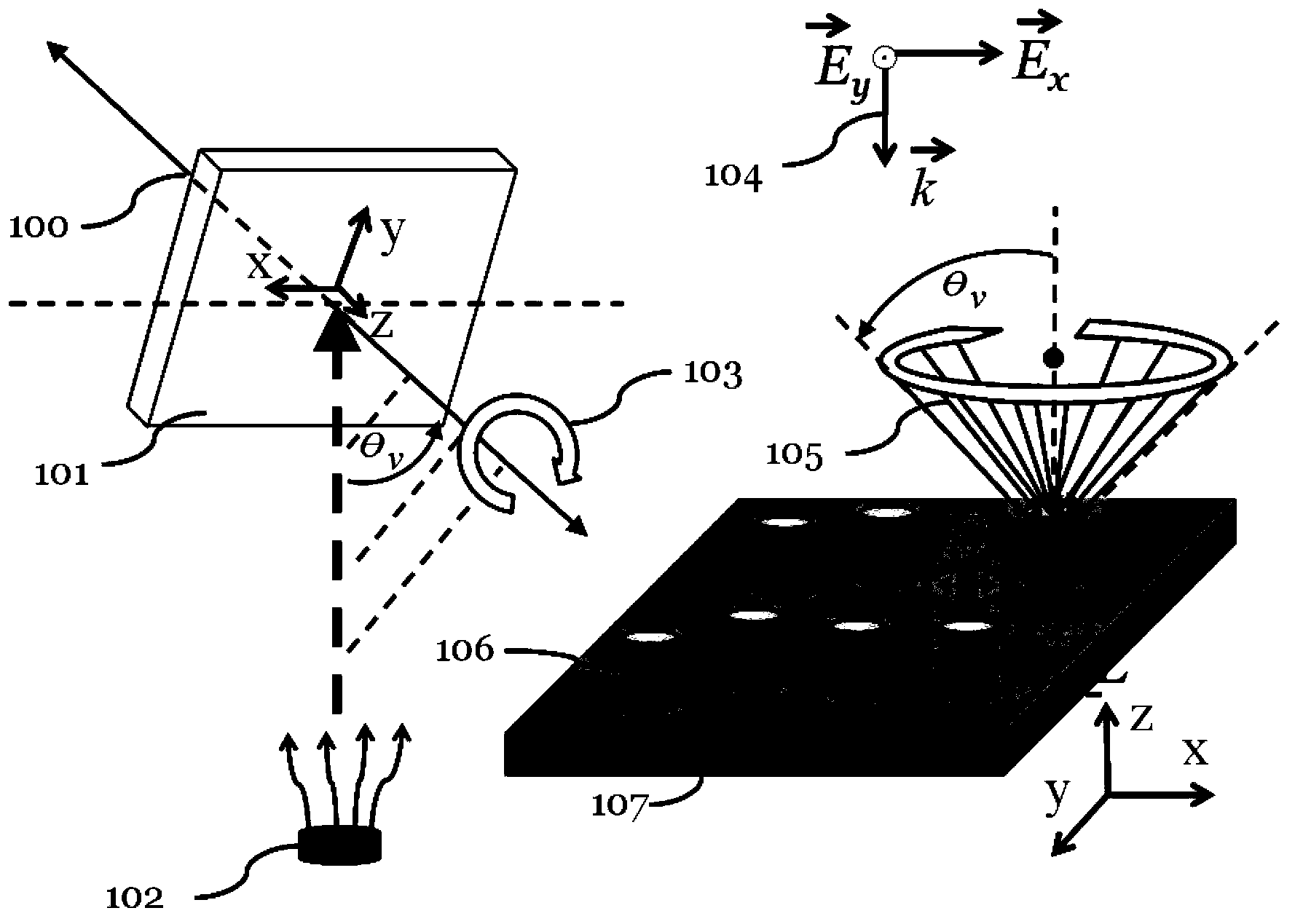

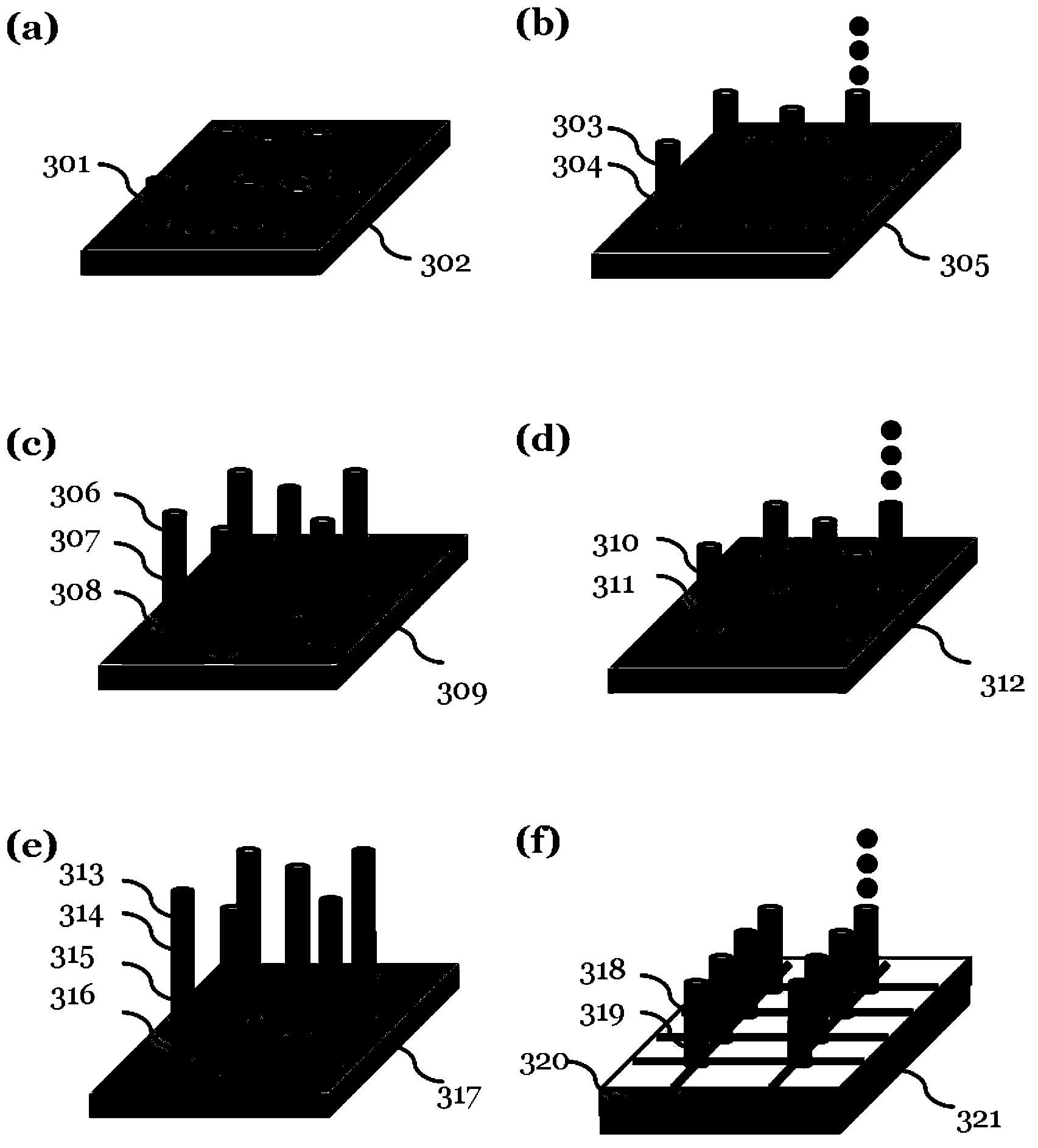

[0044] In order to solve the above technical problems, the present invention provides a method for manufacturing a surface-enhanced Raman spectroscopy (SERS) substrate with at least a metal nano-column structure, including: using an oblique angle deposition method with the rotation of the substrate, and fabricating on the substrate The metal nano column structure and / or the dielectric nano column structure, the nano column structure has a configuration, and the nano column structure is approximately parallel to the normal direction of the substrate after the growth is completed.

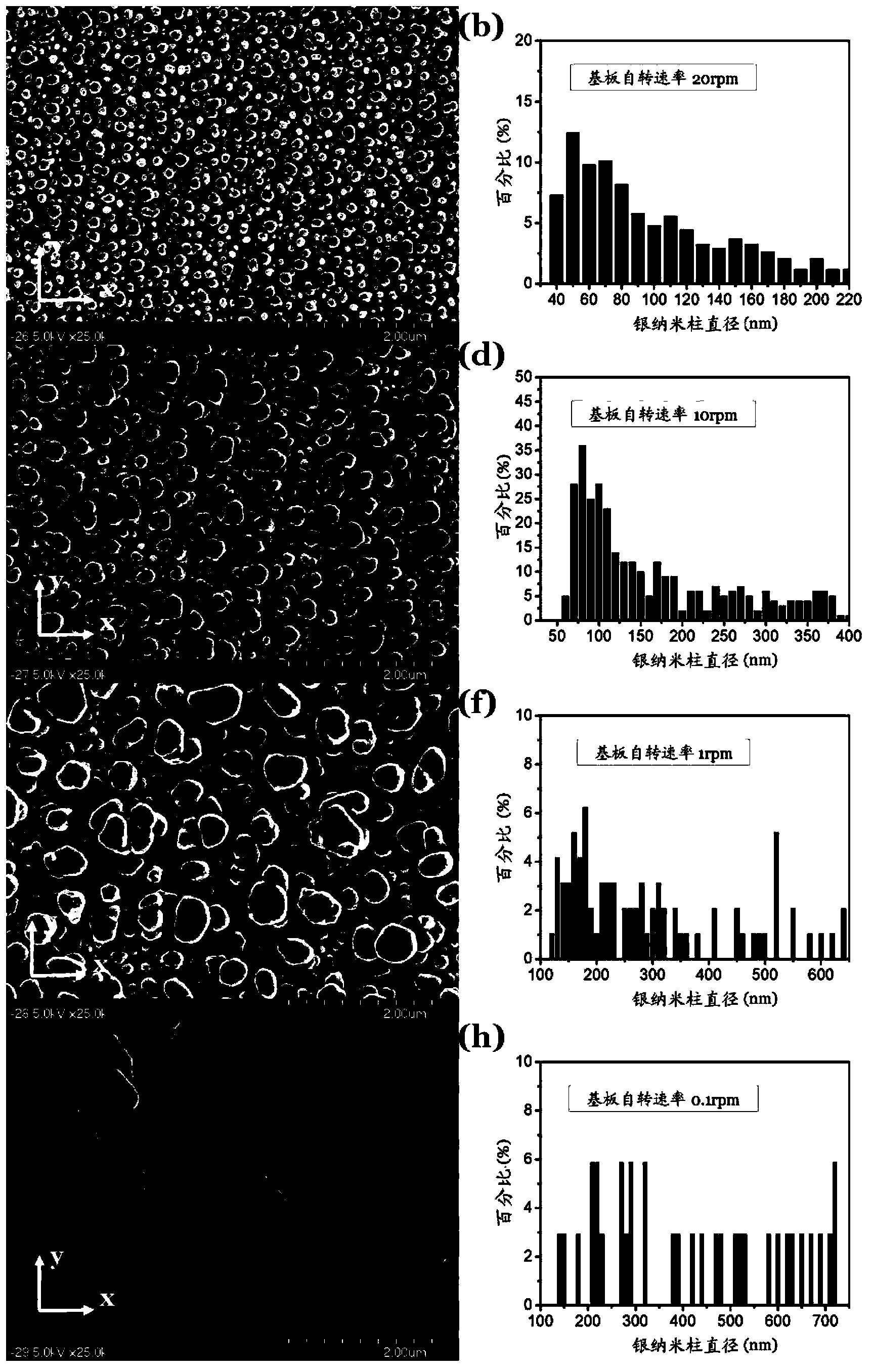

[0045] In the electron gun cavity system, such as figure 1 As shown, the present invention uses oblique angle deposition (oblique angle deposition) with substrate (self) rotation technology to fabricate a silicon wafer substrate 101 (or 107) or a glass substrate 101 (or 107) A plurality of silver nanopillar structures 106, the diameter of the structure is D, and the height (or thickness) is L.

[0046] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com