Preparation and application of Raman enhancer

An enhancer and Raman technology, applied in the field of materials, can solve the problems of limited adsorption and Raman enhancement performance, few hot spots, etc., to achieve the effect of enhancing Raman detection signal, enhancing Raman signal, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

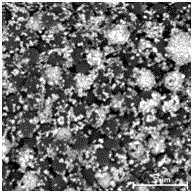

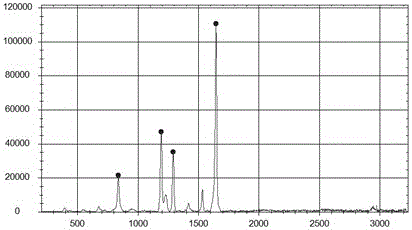

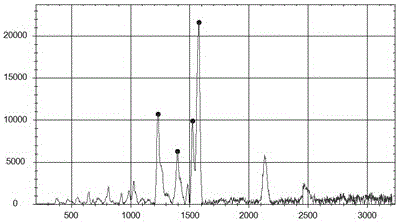

[0023] Example 1: Preparation of PS microspheres with a size of 2 μm, modified Cu nanoparticles and Au nanoparticles, for the detection of paraquat.

[0024] (1) Preparation of PS microspheres

[0025] Stir 20 parts of St, 3 parts of PVP, 0.5 parts of AIBN, and 80 parts of ethanol in a container evenly, pass nitrogen gas for deoxygenation for 30 minutes, heat to 70°C, and react for 12 hours to obtain a white solid. Dried to obtain polystyrene microspheres, set aside.

[0026] (2) PS pretreatment

[0027] Add 1 g PS to concentrated H 2 SO 4 After sonicating for 30 min, centrifuge, then add 4 g / L PdCl 2 , 20 mL / L HCl, ultrasonicated for 30 min, centrifuged, and dried to obtain activated PS.

[0028] (3) Preparation of Cu-PS

[0029] Disperse the activated PS into 0.06M CuSO 4 • 5H 2 O, 12 mL / L HCHO, 0.06M Na 2 In a pH 12 solution composed of EDTA, ultrasonically reacted at 30°C for 15 min, washed and dried.

[0030] (4) Preparation of Au / Cu-PS

[0031] Add 0.1 g Cu-PS...

Embodiment 2

[0034] Example 2: Preparation of PS microspheres with a size of 3 μm, modified Cu nanoparticles and Au nanoparticles, for detecting rhodamine B.

[0035] (1) Preparation of PS microspheres

[0036] Stir 20 parts of St, 2 parts of PVP, 0.5 parts of AIBN, and 80 parts of ethanol in a container evenly, pass nitrogen gas for deoxygenation for 30 minutes, heat to 70°C, and react for 15 hours to obtain a white solid, which is washed with ethanol three times, at 50°C Dried to obtain polystyrene microspheres, set aside.

[0037] (2) PS pretreatment

[0038] Add 1 g PS to concentrated H 2 SO 4 After sonicating for 30 min, centrifuge, then add 4 g / L PdCl 2 , 20 mL / L HCl, ultrasonicated for 30 min, centrifuged, and dried to obtain activated PS.

[0039] (3) Preparation of Cu-PS

[0040] Disperse the activated PS into 0.05M CuSO 4 • 5H 2 O, 12 mL / L HCHO, 0.08 M Na 2 In a solution of pH 12 composed of EDTA, ultrasonically reacted at 35°C for 15 min, washed and dried.

[0041] (4)...

Embodiment 3

[0046] PS microspheres with a size of 5 μm were prepared and modified with Cu nanoparticles and Au nanoparticles for the detection of sildenafil.

[0047] (1) Preparation of PS microspheres

[0048] Stir 40 parts of St, 4 parts of PVP, 0.6 parts of AIBN, and 60 parts of ethanol in a container evenly, pass nitrogen gas for deoxygenation for 30 minutes, heat to 70°C, and react for 16 hours to obtain a white solid. Dried to obtain polystyrene microspheres, set aside.

[0049] (2) PS pretreatment

[0050] Add 1 g PS to concentrated H 2 SO 4 After sonicating for 30 min, centrifuge, then add 4 g / L PdCl 2 , 20 mL / L HCl, ultrasonicated for 30 min, centrifuged, and dried to obtain activated PS.

[0051] (3) Preparation of Cu-PS

[0052] Disperse the activated PS into 0.08M CuSO 4 • 5H 2 O, 12 mL / L HCHO, 0.08 M Na 2 In a solution of pH 12 composed of EDTA, ultrasonically reacted at 35°C for 15 min, washed and dried.

[0053] (4) Preparation of Au / Cu-PS

[0054] Add 0.1 g Cu-P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com