Active-disturbance-rejection control method for temperature of a constant stirring polypropylene reaction kettle

A kind of technology of active disturbance rejection control and control method, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of practical limitation, difficult to obtain models, etc., and achieve rapid dynamic response and good adaptability and the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

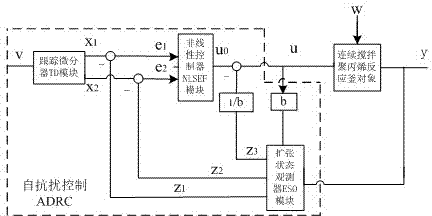

Method used

Image

Examples

Embodiment Construction

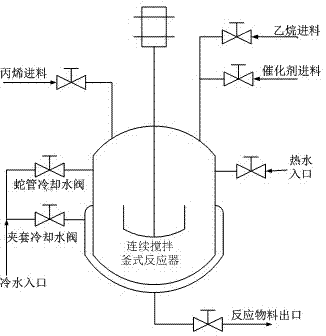

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

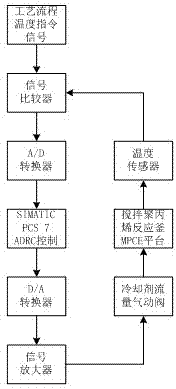

[0032] Taking the polypropylene production reaction model as the controlled object, in the MPCE multifunctional process and control platform, it communicates with the I / O of the slave station through the 4-20mA standard signal, transmits the field data in real time, and completes the functions of online monitoring, recording and query; The upper computer uses SIMATIC PCS7, which is a new generation of compact design controller from Siemens, which eliminates the redundant wiring between the automation station (AS), operator station (OS) and engineer station (ES), and uses a PROFIBUS-DP interface The CPU 416 as the central processing unit is connected with the modular I / O station ET200M through bus connectors and cables. The PCS7 BOX slave rack is equipped with a power supply module (PS), a communication interface module (IM153-2), an 8-channel analog inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com