Manufacturing method of semiconductor device shallow-trench isolation structure

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the STI isolation structure is difficult to further shrink and affect device performance, etc., to reduce width, increase area, and improve integration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as Figure 6 and Figure 8 ~ Figure 14 As shown, this embodiment provides a method for manufacturing a shallow trench isolation structure of a semiconductor device, including the following steps:

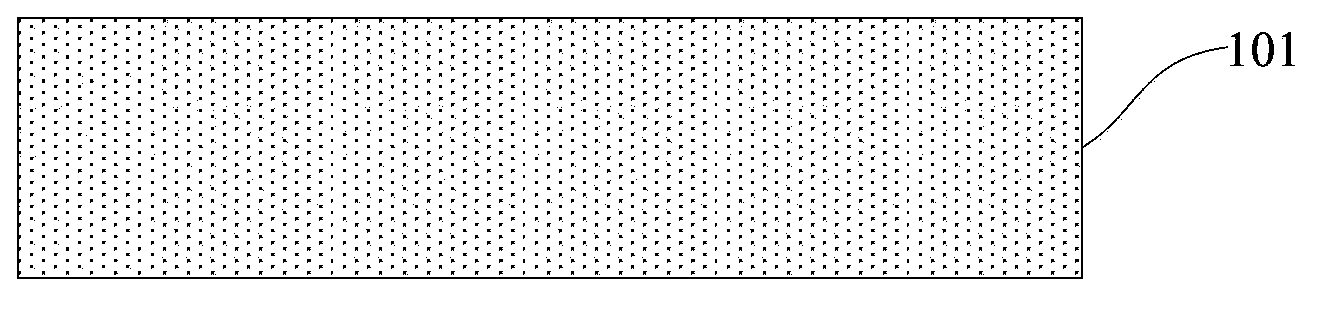

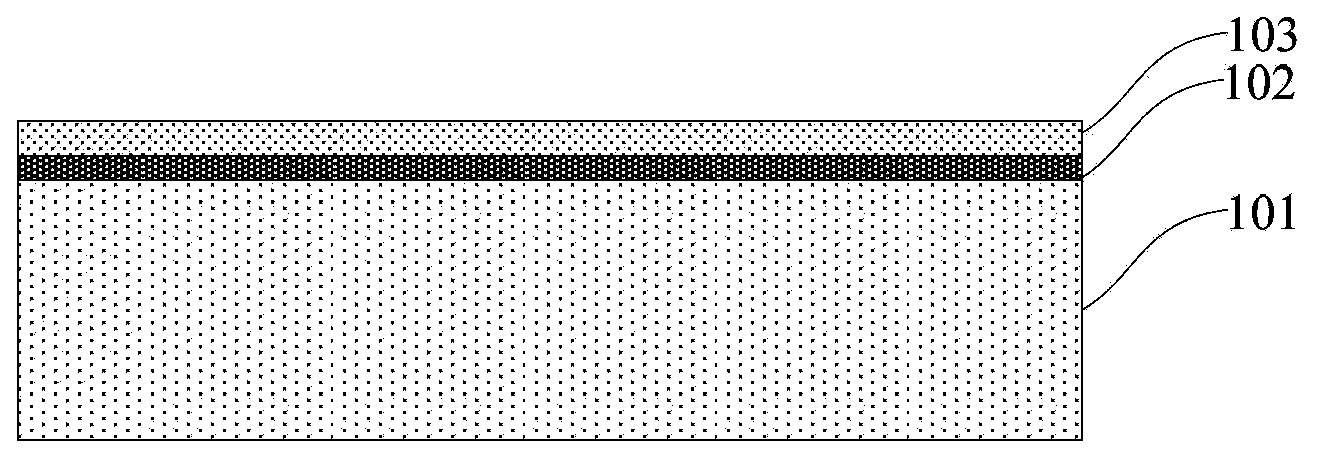

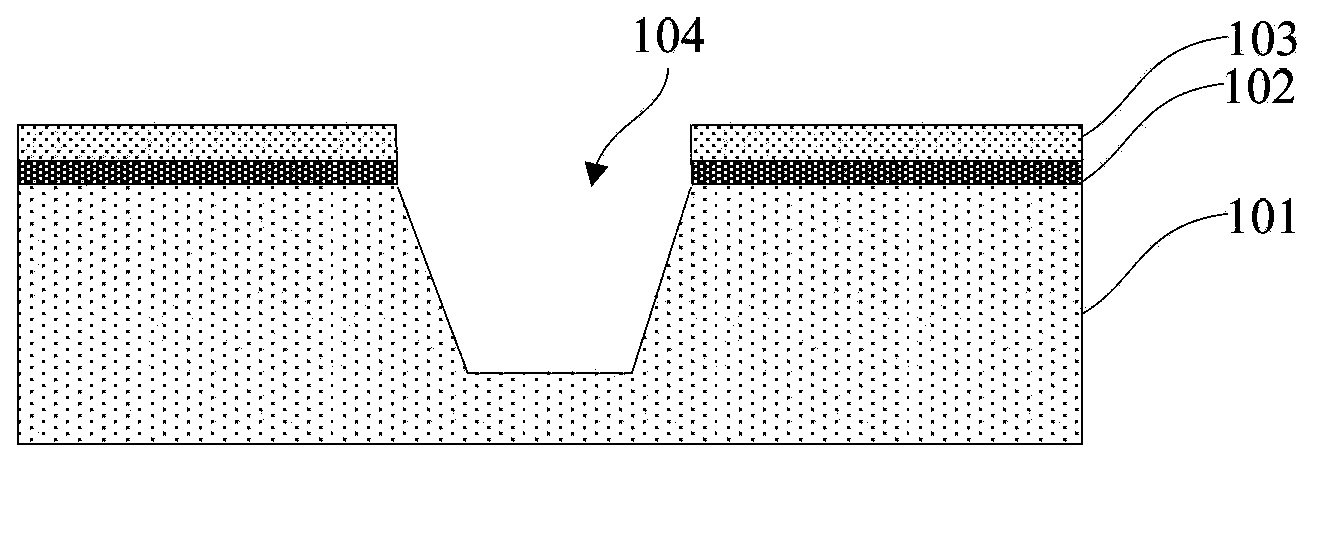

[0046] Such as Figure 6 and Figure 8 ~ Figure 10 As shown, step 1) S11 is first performed, providing a silicon substrate 201, forming a mask layer on the surface of the silicon substrate 201, and forming shallow trenches 204 in the silicon substrate 201 by photolithography.

[0047] As an example, the mask layer is a stack of silicon dioxide layer 202 and silicon nitride layer 203, and its thickness is 30 nm˜200 nm. Of course, in other embodiments, other materials such as high-k dielectric materials can also be used as the mask layer.

[0048] Specifically, in this step, a photoresist (not shown) is formed on the surface of the mask layer, and then an etching window is formed by exposure, and the silicon substrate 201 under the etching window is etched to form a sh...

Embodiment 2

[0059] Such as Figure 7 ~ Figure 15 As shown, this embodiment provides a method for manufacturing a shallow trench isolation structure of a semiconductor device, including the following steps:

[0060] Such as Figure 7 ~ Figure 10 As shown, step 1) S21 is first performed, providing a silicon substrate 201, forming a mask layer on the surface of the silicon substrate 201, and forming shallow trenches 204 in the silicon substrate 201 by photolithography.

[0061] As an example, the mask layer is a stack of silicon dioxide layer 202 and silicon nitride layer 203, and its thickness is 30 nm˜200 nm. Of course, in other embodiments, other materials such as high-k dielectric materials can also be used as the mask layer.

[0062] Specifically, in this step, a photoresist (not shown) is formed on the surface of the mask layer, and then an etching window is formed by exposure, and the silicon substrate 201 under the etching window is etched to form a shallow trench groove 204 . In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com