Method for producing an ultrasonic converter core with embedded piezoelectric converter element

A technology of piezoelectric converters and converters, which is applied to fluids, instruments, and measuring devices that utilize vibrations, and can solve problems such as no signal, damage to ultrasonic sensors, and limitations in system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

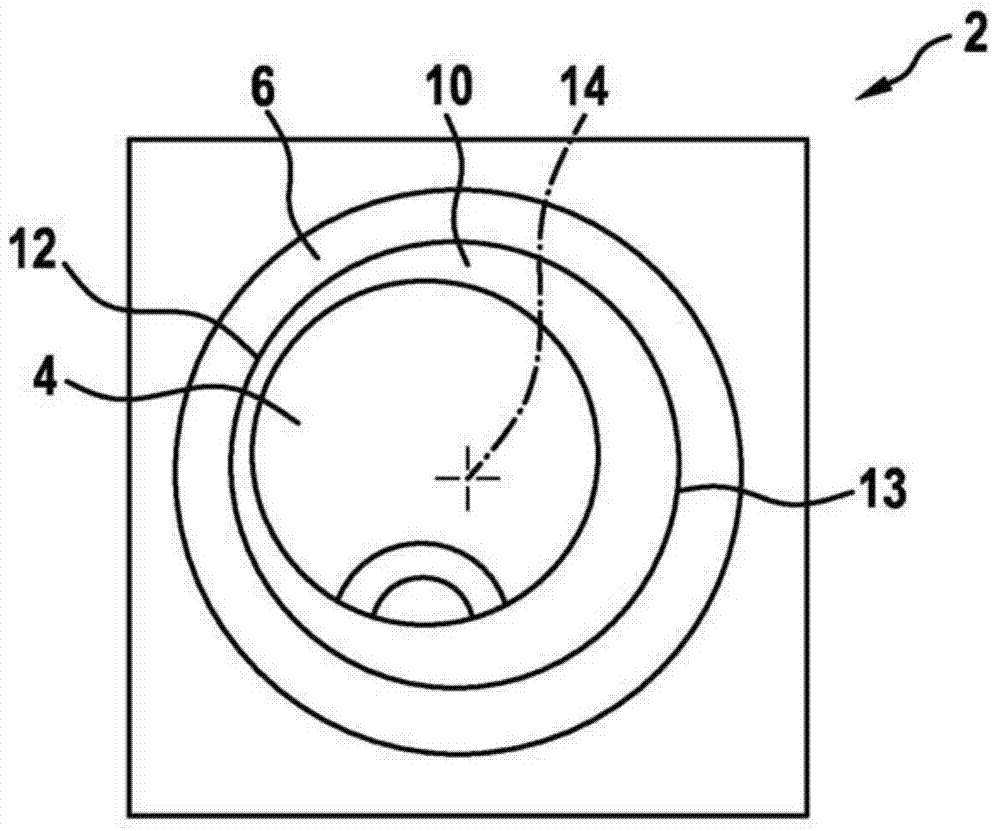

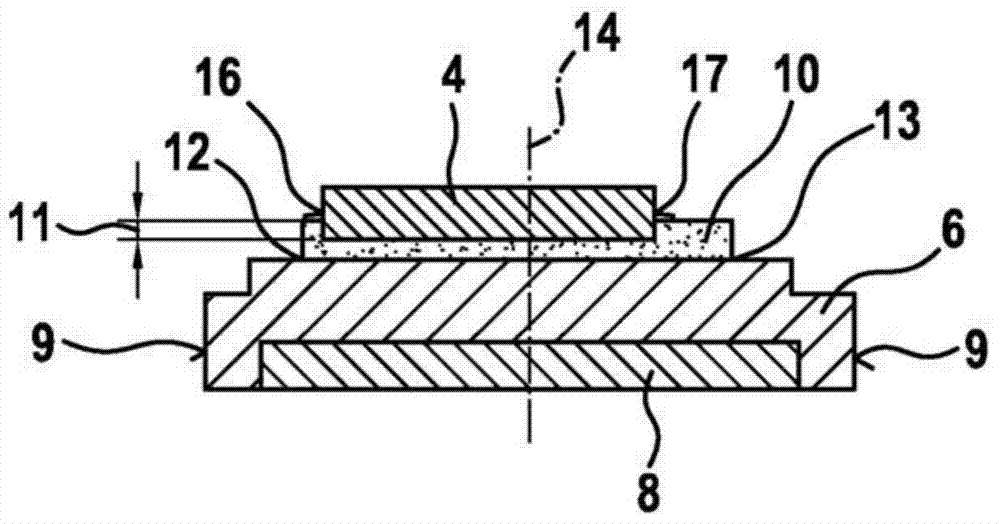

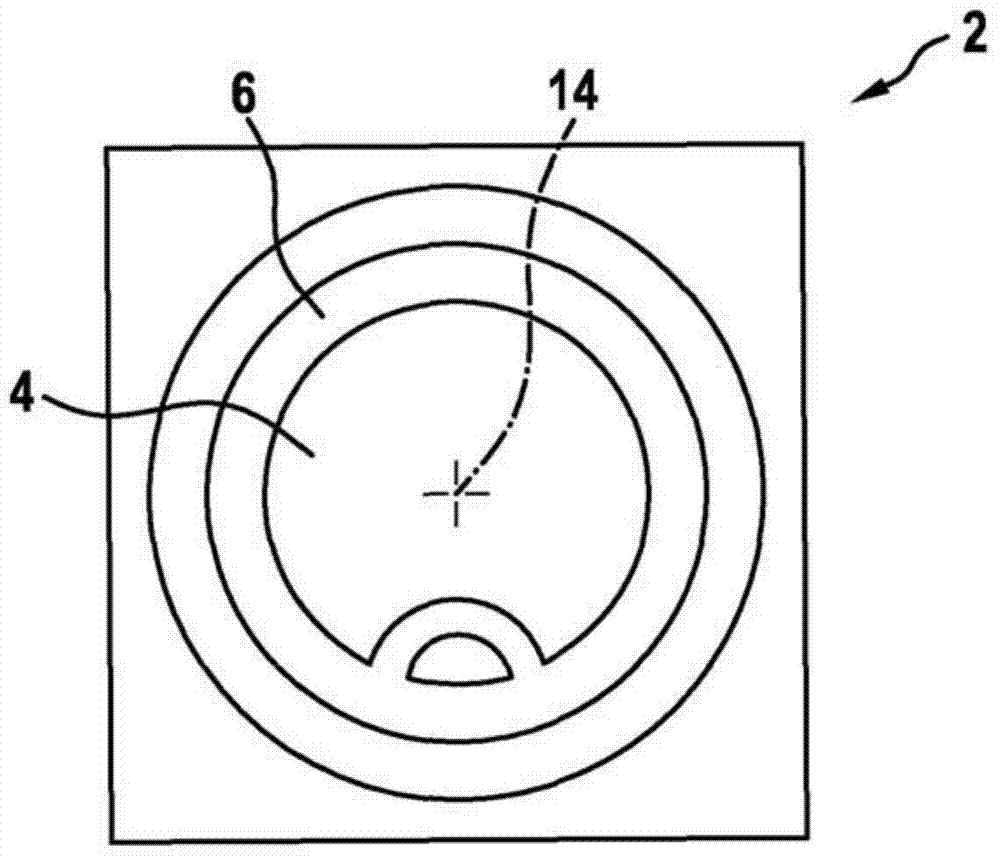

[0033] exist figure 1 and figure 2The ultrasonic transducer 2 shown in includes a piezoelectric transducer element 4 and an adaptor 8 . An adhesive layer 10 is introduced between the adaptor 8 and the piezoelectric element 4 .

[0034] As the primary electro-mechanical conversion principle, for example, electrostatic effects, magnetostrictive effects, or piezoelectric effects are utilized in the ultrasonic transducer 2 . In the case of a piezoceramic as primary converter element, different resonant vibration modes result, which, depending on the geometry, are more or less pronounced, or which are coupled differently to each other or Decoupling. In the case of a simple square or cylindrical geometry, firstly the following vibration modes can be derived, all of which can be applied, at least in principle, to ultrasonic conversion:

[0035] - thickness vibrations of thin piezoelectric sheets, wherein, in particular, when the diameter of the piezoelectric sheet is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com