Method for crystallizing and separating ammonium metavanadate in ammonium vanadium slag leaching solution

A technology of ammonium metavanadate and ammonium leaching of vanadium slag, which is applied in the field of vanadium chemical metallurgy, can solve the problems of ineffective recovery of vanadium, and achieve the effects of easy control, high vanadium crystallization rate, and solution to vanadium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

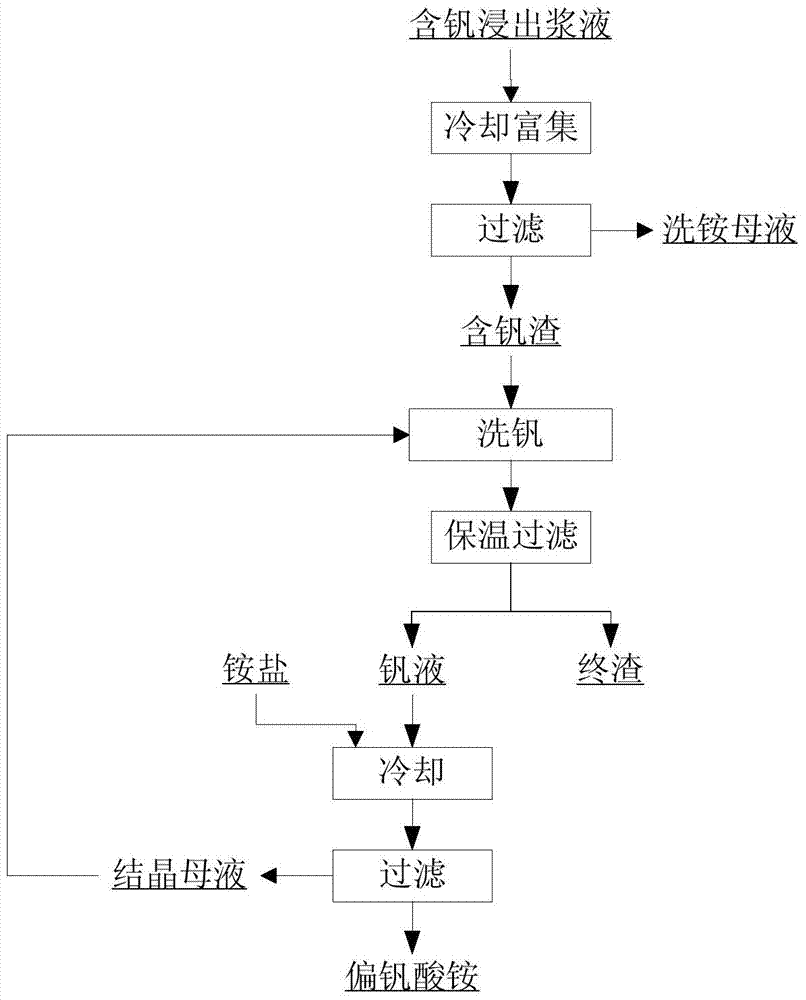

Image

Examples

Embodiment 1

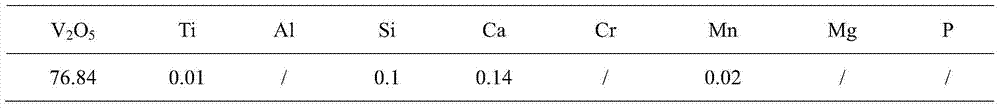

[0030] The vanadium slag ammonium immersion slurry used in this embodiment mainly includes vanadium slag, ammonium metavanadate and ammonium bicarbonate, and the slurry undergoes the following three steps in sequence to prepare ammonium metavanadate crystals.

[0031] (1) enrichment: 500mL temperature is 70 ℃, V 2 o 5 The vanadium slag ammonium immersion slurry with a concentration of 15.72g / L and an ammonium ion concentration of 68.35g / L was cooled and stirred for 3 hours, the temperature was lowered to 25°C, and then the slurry was subjected to liquid-solid separation to obtain vanadium slag and filtrate. Wherein the ammonium metavanadate crystal is enriched in the slag, and the filtrate volume is 490mL, V 2 o 5 The concentration is 5.01g / L, the ammonium ion concentration is 60.11g / L, and the filtrate is used for the next ammonium leaching test.

[0032] (2) Washing: 500mL V 2 o 5 The vanadium-containing solution with a concentration of 3.21g / L and an ammonium ion conce...

Embodiment 2

[0040] The vanadium slag ammonium immersion slurry used in this embodiment mainly includes vanadium slag, ammonium metavanadate and ammonium carbonate, and the slurry undergoes the following three steps in sequence to prepare ammonium metavanadate crystals.

[0041] (1) enrichment: 500mL temperature is 90 ℃, V 2 o 5 The vanadium slag ammonium immersion slurry with a concentration of 32.1g / L and an ammonium ion concentration of 91.14g / L was cooled and stirred for 4 hours, the temperature dropped to 45°C, and then the slurry was subjected to liquid-solid separation to obtain vanadium slag and filtrate. Wherein the ammonium metavanadate crystal is enriched in the slag, and the filtrate volume is 493mL, V 2 o 5 The concentration is 6.83g / L, the ammonium ion concentration is 90.05g / L, and the filtrate is used for the next ammonium leaching test.

[0042] (2) Washing: 500mL V 2 o 5 The vanadium-containing solution with a concentration of 4.22g / L and an ammonium ion concentratio...

Embodiment 3

[0049] The vanadium slag ammonium immersion slurry used in this embodiment mainly includes vanadium slag, ammonium metavanadate and ammonium sulfate, and the slurry undergoes the following three steps in order to prepare ammonium metavanadate crystals.

[0050] (1) enrichment: 500mL temperature is 78 ℃, V 2 o 5 The vanadium slag ammonium immersion slurry with a concentration of 25.78g / L and an ammonium ion concentration of 27.34g / L was cooled and stirred for 0.5h, the temperature dropped to 15°C, and then the slurry was subjected to liquid-solid separation to obtain vanadium slag and filtrate. Wherein the ammonium metavanadate crystal is enriched in the slag, and the filtrate volume is 490mL, V 2 o 5 The concentration is 8.45g / L, the ammonium ion concentration is 26.09g / L, and the filtrate is used for the next ammonium leaching test.

[0051] (2) Washing: 500mL V 2 o 5 The vanadium-containing solution with a concentration of 10.39g / L and an ammonium ion concentration of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com