Ultra-high-strength cable steel and its production method

A cable steel, ultra-high-strength technology, applied in the field of electrical cable steel, can solve the problems of low tensile strength, can not meet the requirements of ultra-high-strength cable steel, low carbon and manganese content, etc., to achieve high strength, good cold drawing Performance, Effect of High Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

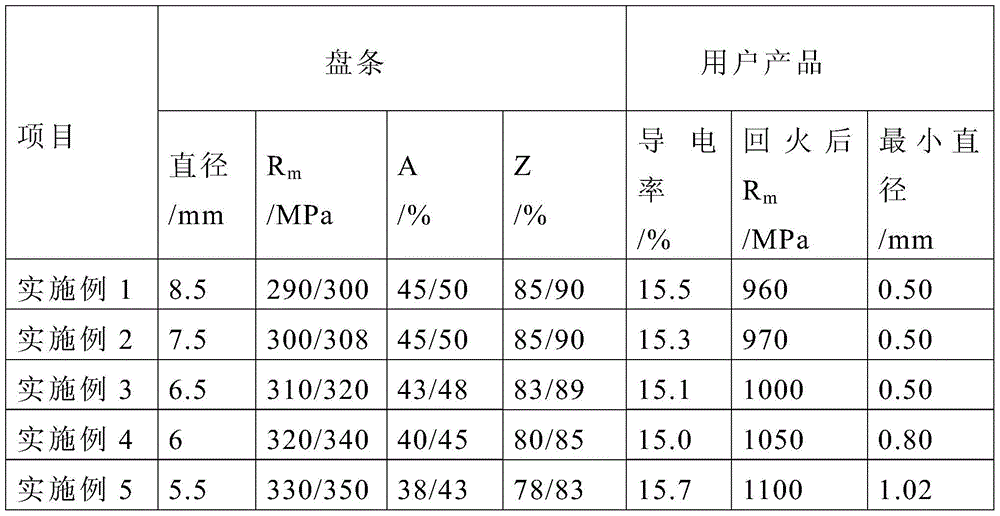

Examples

Embodiment 1

[0020] An ultra-high-strength cable steel, its chemical composition by weight percentage is: C: 0.05%, Si: 0.09%, Mn: 0.15%, P: 0.020%, S: 0.010%, Als: 0.03%, the balance is Fe and inevitable impurities. Product diameter 8.5mm.

[0021] The production method of the ultra-high strength cable steel is carried out according to the usual pure steel process, and includes the following steps: molten iron desulfurization, converter smelting, argon blowing, RH furnace treatment, continuous casting, billet heating, high-speed wire rolling, Steyr Mo control cold, where:

[0022] When the molten iron is desulfurized, the weight percentage of each element in the incoming molten iron is controlled as follows: S≤0.025%, Mn≤0.30%, Cu≤0.060%, Si≤0.80%, the incoming molten iron temperature is ≥1250°C, and the molten iron enters the furnace. The weight percentage of S is less than or equal to 0.001%, and the molten iron is clean; self-retained scrap or low-sulfur scrap is used, and scrap cont...

Embodiment 2

[0031] A kind of ultra-high-strength cable steel, according to the steel composition requirements, the chemical composition of the molten steel is: C: 0.01%, Si: 0.05%, Mn: 0.09%, P: 0.018%, S: 0.008%, Als: 0.01%, and the rest The amount is Fe and inevitable impurities. Product diameter 7.5mm.

[0032] The production method of this ultra-high-strength cable steel, the basic steps are operated according to the method of embodiment 1, and the difference is:

[0033] During converter smelting, the target temperature for tapping is 1670°C, and the tapping is not pre-deoxidized. When blowing argon, 0.7kg / ton of Al shot and 0.2kg / ton of calcium carbide are sprayed on the slag surface before RH is applied to the ladle. The amount (TFe) is reduced to below 10%, and the argon station is blown softly for 3 minutes;

[0034] During the RH furnace treatment, the RH furnace treatment time is 30min, and the de-C, final deoxidation and composition fine-tuning are carried out in the RH furn...

Embodiment 3

[0038]A kind of ultra-high-strength cable steel, according to the steel composition requirements, the chemical composition of the molten steel is: C: 0.02%, Si: 0.01%, Mn: 0.20%, P: 0.015%, S: 0.010%, Als: 0.008%, and the rest The amount is Fe and inevitable impurities.

[0039] The production method of this ultra-high-strength cable steel, the basic steps are the same as in Example 1, and the difference is:

[0040] During converter smelting, the target temperature for tapping is 1650 °C; the tapping is not pre-deoxidized. When blowing argon, 0.3 kg / ton of Al shot and 0.2 kg / ton of calcium carbide are sprayed on the slag surface before RH is applied to the ladle, and the total amount of iron oxide in the slag is removed (TFe) was reduced to below 10%, and the argon station was blown softly for 2 minutes. In the case of RH furnace treatment, the RH furnace treatment time is 200min, and the de-C, final deoxidization and composition fine-tuning are carried out in the RH furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com