High-performance duplex stainless steel wire rope alloy material and preparation method thereof

A technology of duplex stainless steel and alloy materials, used in textiles, papermaking, textile cables, etc., can solve the problems of difficult deformation, difficult two-phase ratio, large work hardening, etc., achieve good cold drawing performance, avoid serious imbalance, surface bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

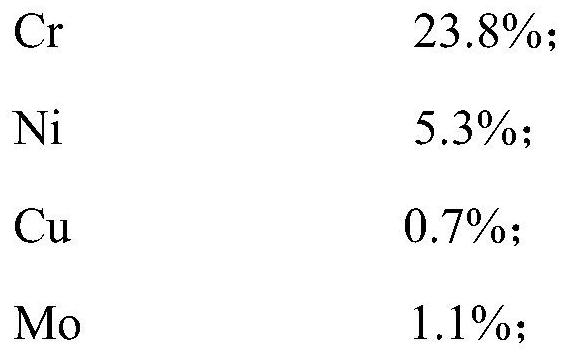

[0037] In this embodiment, a high-performance duplex stainless steel wire rope alloy material has the following composition and mass percentage:

[0038]

[0039]

[0040] A preparation method of the high-performance duplex stainless steel wire rope of the present embodiment, the steps are as follows:

[0041] a. Adopt intermediate frequency induction smelting and AOD smelting process. When raw materials are batched, the raw materials are weighed according to the composition of the high-performance duplex stainless steel wire rope alloy material prepared by the target of this embodiment; all raw materials weighed after batching are passed through the intermediate frequency furnace Melted, then transferred to AOD furnace for refining, nitrogen content control, and then cast into duplex stainless steel alloy billets;

[0042] b. duplex stainless steel wire rod: the duplex stainless steel alloy billet prepared in the step a is processed by a hot rolling process to obtain a ...

Embodiment 2

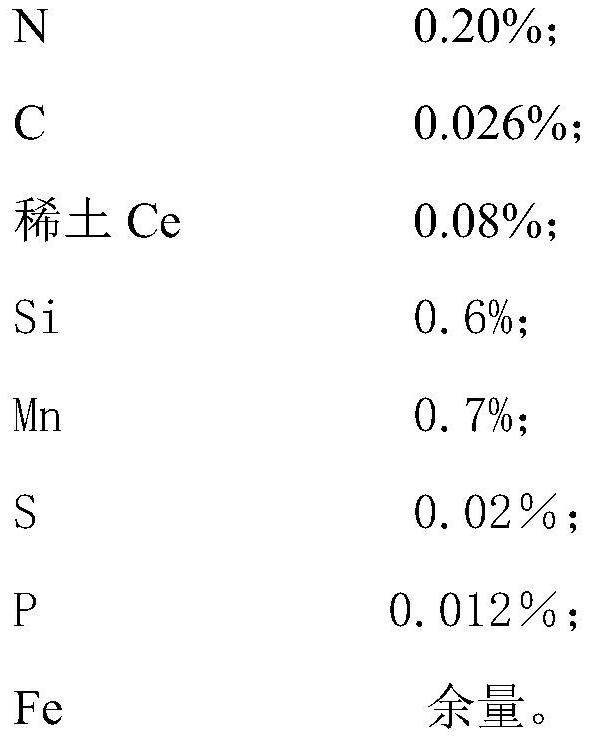

[0047] In this embodiment, a high-performance duplex stainless steel wire rope alloy material has the following composition and mass percentage:

[0048]

[0049]

[0050] A preparation method of the high-performance duplex stainless steel wire rope of the present embodiment, the steps are as follows:

[0051] a. Adopt intermediate frequency induction smelting and AOD smelting process. When raw materials are batched, the raw materials are weighed according to the composition of the high-performance duplex stainless steel wire rope alloy material prepared by the target of this embodiment; all raw materials weighed after batching are passed through the intermediate frequency furnace Melted, then transferred to AOD furnace for refining, nitrogen content control, and then cast into duplex stainless steel alloy billets;

[0052] b. duplex stainless steel wire rod: the duplex stainless steel alloy billet prepared in the step a is processed by a hot rolling process to obtain a ...

Embodiment 3

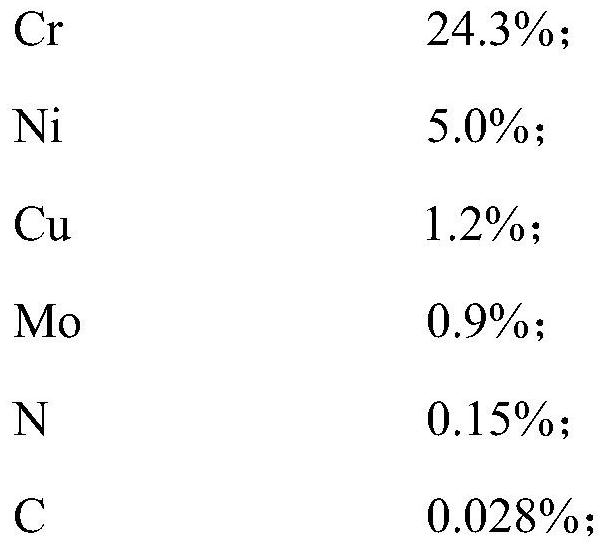

[0057] In this embodiment, a high-performance duplex stainless steel wire rope alloy material has the following composition and mass percentage:

[0058]

[0059]

[0060] A preparation method of the high-performance duplex stainless steel wire rope of the present embodiment, the steps are as follows:

[0061] a. Adopt intermediate frequency induction smelting and AOD smelting process. When raw materials are batched, the raw materials are weighed according to the composition of the high-performance duplex stainless steel wire rope alloy material prepared by the target of this embodiment; all raw materials weighed after batching are passed through the intermediate frequency furnace Melted, then transferred to AOD furnace for refining, nitrogen content control, and then cast into duplex stainless steel alloy billets;

[0062] b. duplex stainless steel wire rod: the duplex stainless steel alloy billet prepared in the step a is processed by a hot rolling process to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com