Steel for shielding wire and its production method

A technology of shielded wire and molten steel, applied in the field of steel for electrical cables, to achieve good cold drawing performance and no deformation of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

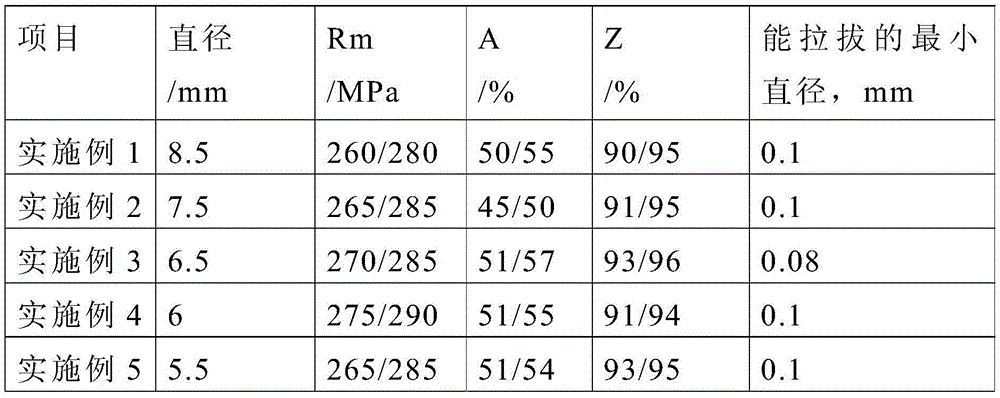

Examples

Embodiment 1

[0021] A steel for shielding wires, according to the requirements of steel composition, the chemical composition of molten steel is: C: 0.001%, Si: 0.01%, Mn: 0.15%, P: 0.005%, S: 0.009%, Ti: 0.01%, the balance It is Fe and unavoidable impurities.

[0022] The production method of the steel for shielding wire is carried out according to the usual pure steel process, including the following steps: blast furnace molten iron desulfurization treatment, converter smelting, argon blowing, RH furnace treatment, continuous casting, billet acceptance, billet heating, high-wire rolling , Steyrmo controlled cooling, volume collection, and the steps of bundling and packaging, wherein,

[0023] Desulfurization treatment of hot metal in blast furnace: use magnesium powder desulfurization process, and control the percentage of S in the station to be ≤0.010%;

[0024] During converter smelting, the whole process of top-bottom compound blowing is carried out, the content of each element [C]≤0...

Embodiment 2

[0032] A steel for shielding wires, according to the steel composition requirements, the chemical composition of molten steel is: C: 0.002%, Si: 0.008%, Mn: 0.12%, P: 0.007%, S: 0.003%, Ti: 0.03% , the balance is Fe and unavoidable impurities.

[0033] The production method of steel for this shielding wire, basic steps are the same as embodiment 1, and difference is:

[0034] When blowing argon: argon pressure is 0.7MPa, argon flow rate is 12Nm 3 / min, the molten steel arrives at the station and blows argon for 7 minutes, then sprinkles aluminum shot and calcium carbide on the slag surface of the large tank, the dosage of aluminum shot is 52kg per ton of molten steel, and the dosage of calcium carbide is 15kg per ton of molten steel;

[0035] During continuous casting, the target superheat of molten steel in the tundish is 40°C, and the casting speed is 1.0m / min;

[0036]When the billet is heated, the temperature in the soaking section is 1150°C, the cross-sectional temperat...

Embodiment 3

[0039] A steel for shielding wires, according to the steel composition requirements, the chemical composition of molten steel is: C: 0.003%, Si: 0.006%, Mn: 0.10%, P: 0.009%, S: 0.005%, Ti: 0.10%, the balance It is Fe and unavoidable impurities. The product diameter is 6.5mm.

[0040] The production method of steel for this shielding wire, basic steps are the same as embodiment 1, and difference is:

[0041] When blowing argon: Argon pressure is 0.4MPa, argon flow rate is 15.0Nm 3 / min, the molten steel arrives at the station and blows argon for 10 minutes, then sprinkles aluminum shot and calcium carbide on the slag surface of the large tank, the dosage of aluminum shot is 50kg per ton of molten steel, and the dosage of calcium carbide is 15kg per ton of molten steel;

[0042] During continuous casting, the target superheat of molten steel in the tundish is 35°C, and the casting speed is 0.9m / min;

[0043] When the billet is heated, the temperature in the soaking section i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com