Vertical wall heat insulation silo

A technology of thermal insulation and thermal insulation layer, applied in thermal insulation, roof insulation materials, building components and other directions, can solve problems such as poor thermal insulation effect of vertical silos, and achieve good waterproof effect, lower temperature, and thermal insulation. good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

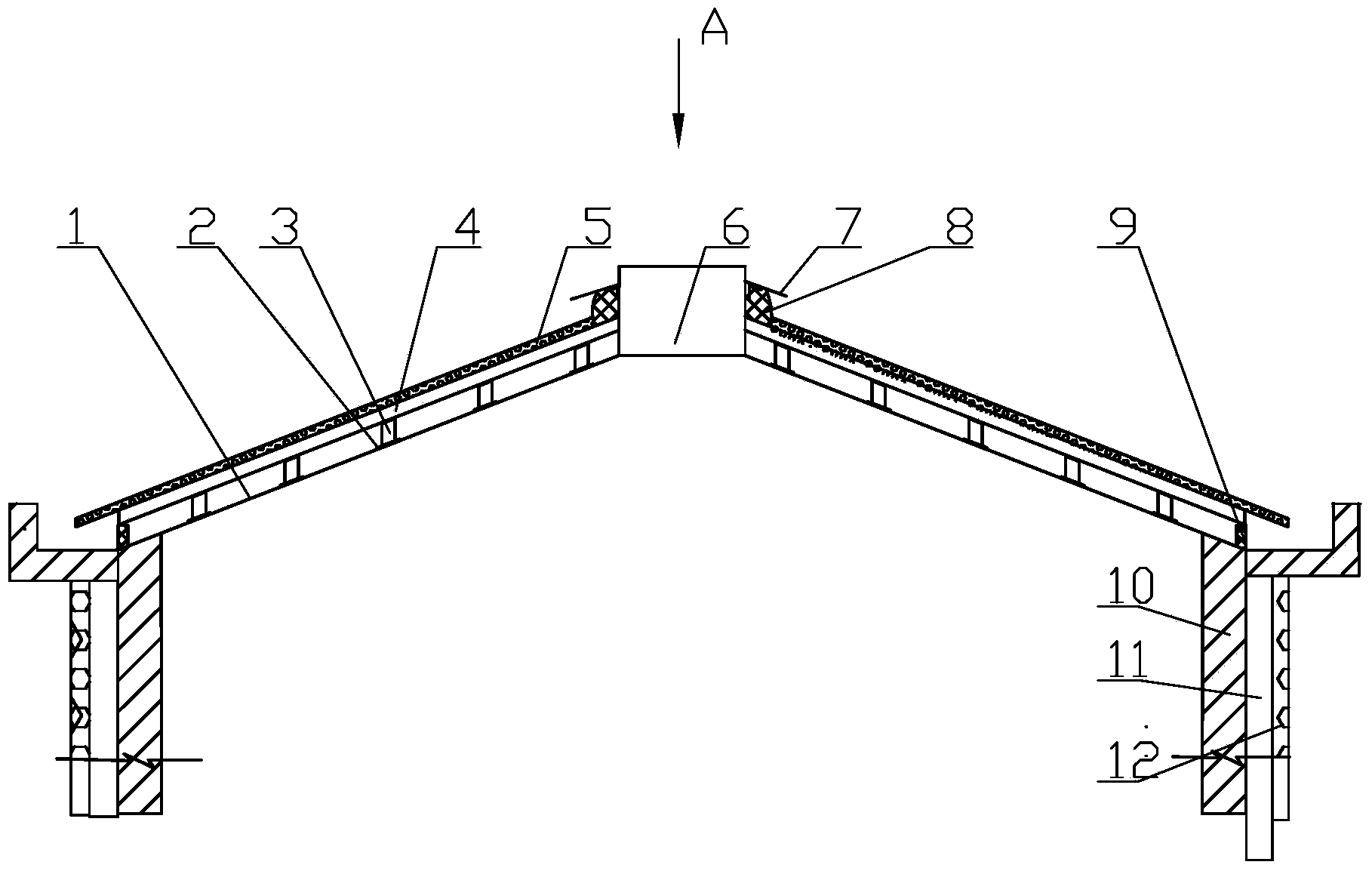

[0021] Such as figure 1 Shown: The top 1 of the original silo is provided with an overhead magnesite thermal insulation layer 5, and there are multiple silo top piers 3 on the silo top 1, and the bottom of the silo top pier 3 is fixed by piers Block 2 is fixed on the silo roof 1, the multi-circle silo roof keel 4 is installed on the silo roof buttress 3, the silo roof magnesite thermal insulation layer 5 is installed on the silo roof keel 4, and the silo roof magnesite thermal insulation layer 5 There is a gap of 150mm between the silo roof 1 and the two ends of the gap are respectively provided with a rain shield 7, a plastic dipping anti-bird net ventilation window 8 and a plastic dipping anti-bird net ventilation window 9. The warehouse body 10 of the original vertical silo is provided with a warehouse body keel 11, and the warehouse body magnesite thermal insulation layer 12 is installed on the warehouse body keel 11.

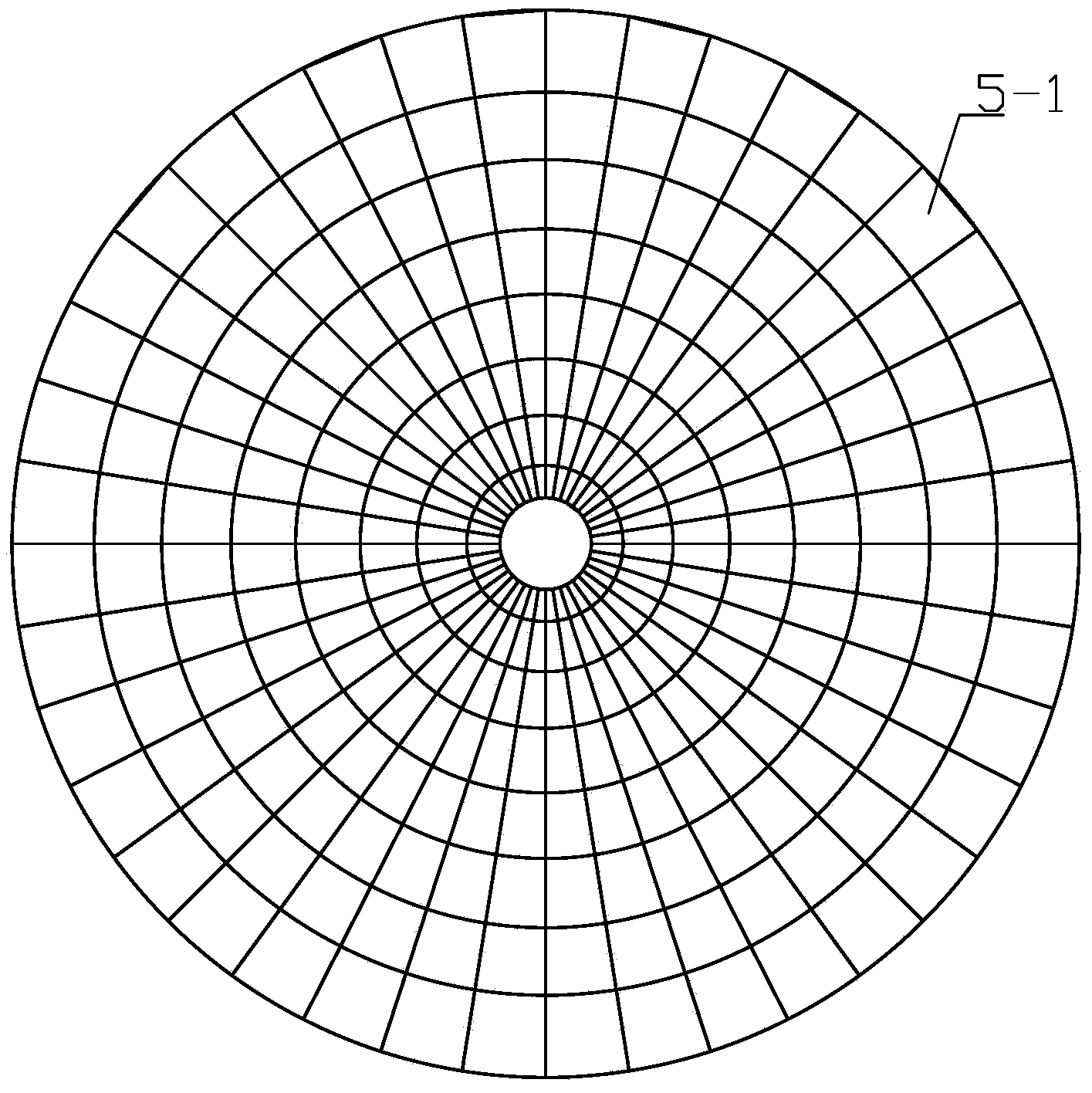

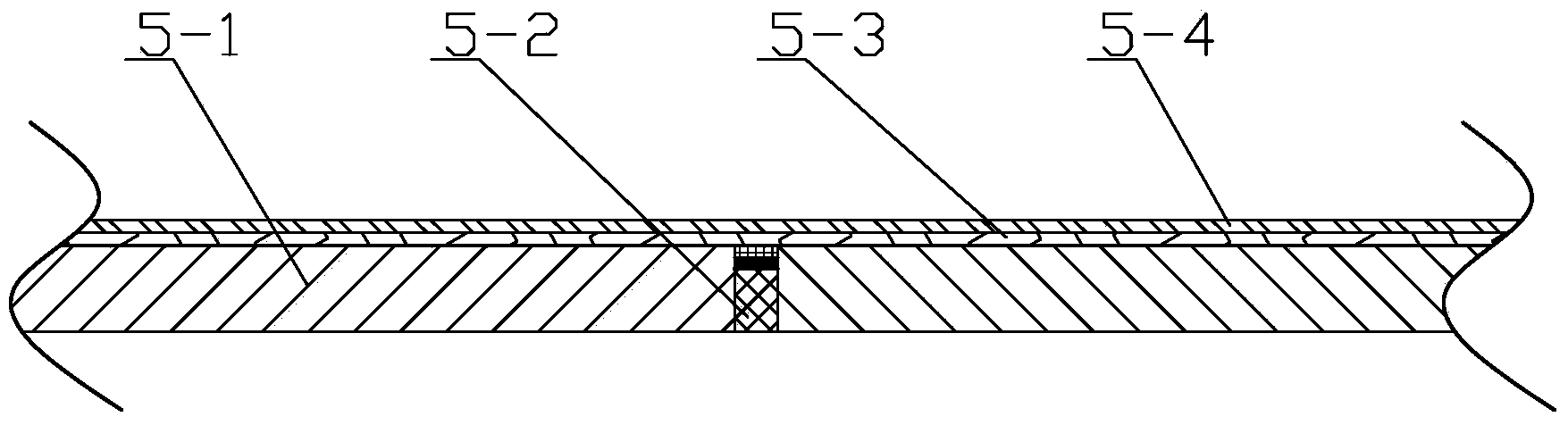

[0022] Such as figure 2 As shown: the magnesite thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com