High-sensitivity silicon piezoresistive pressure sensor and its preparation method

A pressure sensor and high-sensitivity technology, applied in the field of pressure sensors and their preparation, high-sensitivity silicon piezoresistive pressure sensors and their preparation, can solve the problem of increasing the difficulty of the piezoresistor process, increasing the position change rate, and increasing the thinning process Difficulty and other problems, to achieve the effect of improving yield and reliability, improving stability, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific drawings and embodiments.

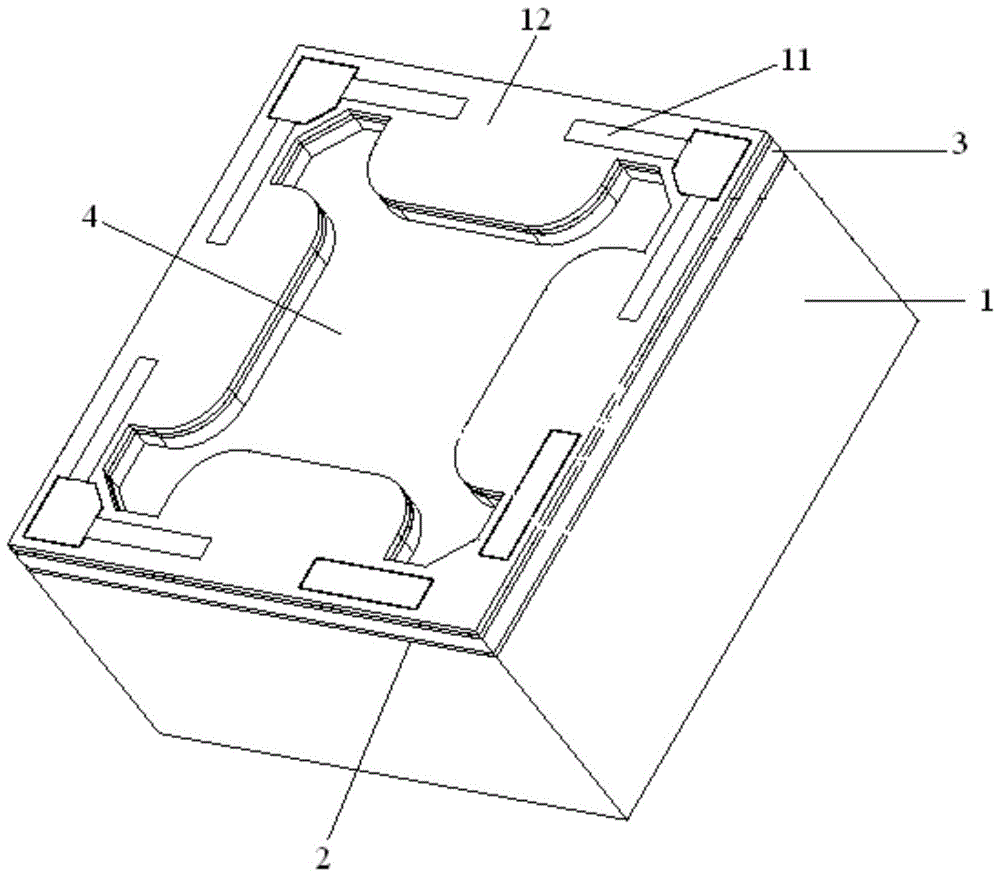

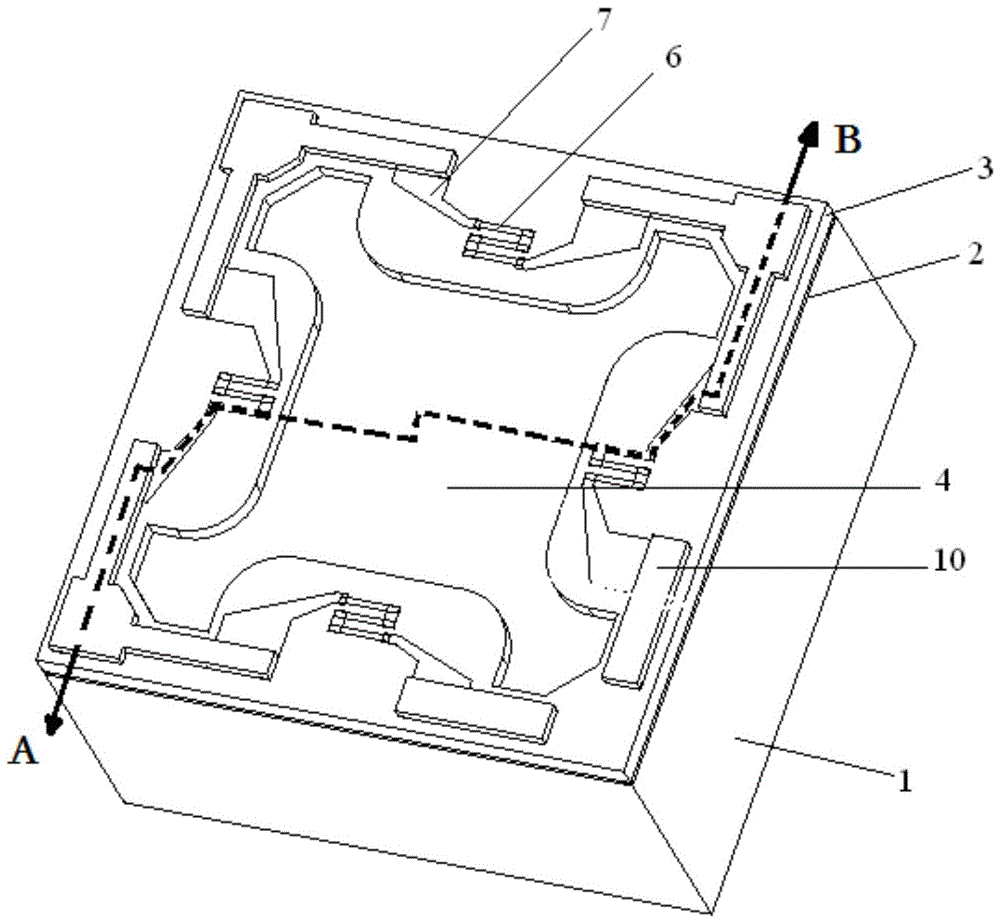

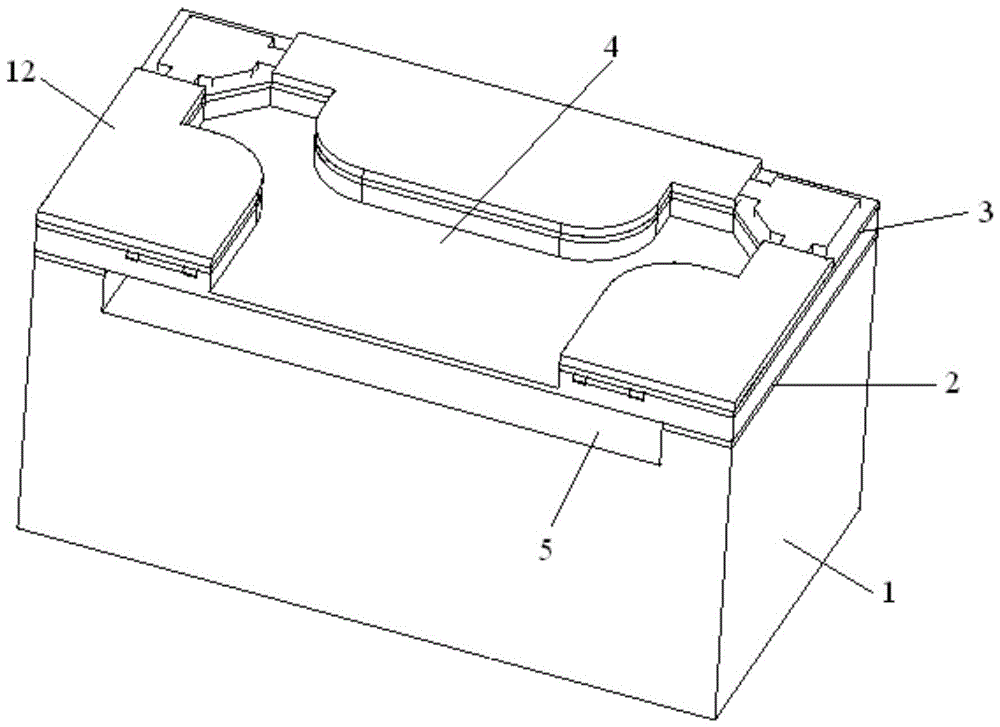

[0056] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: In order to improve the sensitivity without increasing the area of the pressure sensor and the difficulty of the process, the present invention includes a silicon substrate 1; The upper part is sealed to form a vacuum chamber 5; the central area of the strain film 3 is concavely provided with a stress concentration area 4, and the stress concentration area 4 is located directly above the vacuum chamber 5; strain resistance 6, the strain resistance 6 is located at the outer circle of the stress concentration area 4 and above the vacuum chamber 5; the strain resistance 6 on the strain film 3 is electrically connected through the metal electrode 10 above the strain film 3 to form a Wheatstone bridge ; The metal electrode 10 and the strain film 3 are separated by the protective layer 9 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com