Small-diameter tube nondestructive testing method based on phased array ultrasonic flaw detector

A non-destructive testing and ultrasonic technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of human injury, installation time, and low sensitivity, and achieve the effect of reducing detection cost, avoiding repeated detection, and improving debugging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The phased array ultrasonic flaw detector includes probe, scanning frame, wedges, host, battery, etc. When the phased array ultrasonic flaw detector is used to detect the workpiece, the probe is fixed on the scanning frame, and the wedge is fixed at the front end of the probe. For different specifications of the workpiece, different specifications of the wedges are selected.

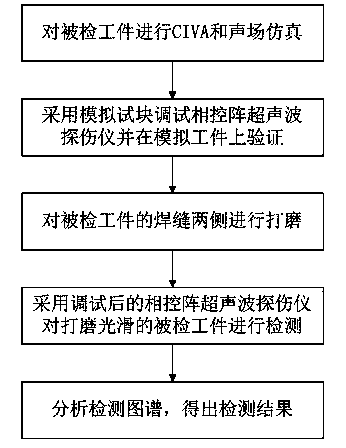

[0026] Such as figure 1 As shown, a small-diameter tube non-destructive testing method based on phased array ultrasonic flaw detector includes the following steps:

[0027] S1. Before on-site inspection, perform CIVA and sound field simulation for the specifications of the inspected workpiece (thickness, weld diameter, etc.), and input the simulation results into the phased array ultrasonic flaw detector.

[0028] In the simulation, the input parameters include the groove angle, thickness, pipe diameter, weld reinforcement, and gap of the inspected workpiece, and the output parameters include the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com