Difunctional composite porous membrane and preparation and application thereof

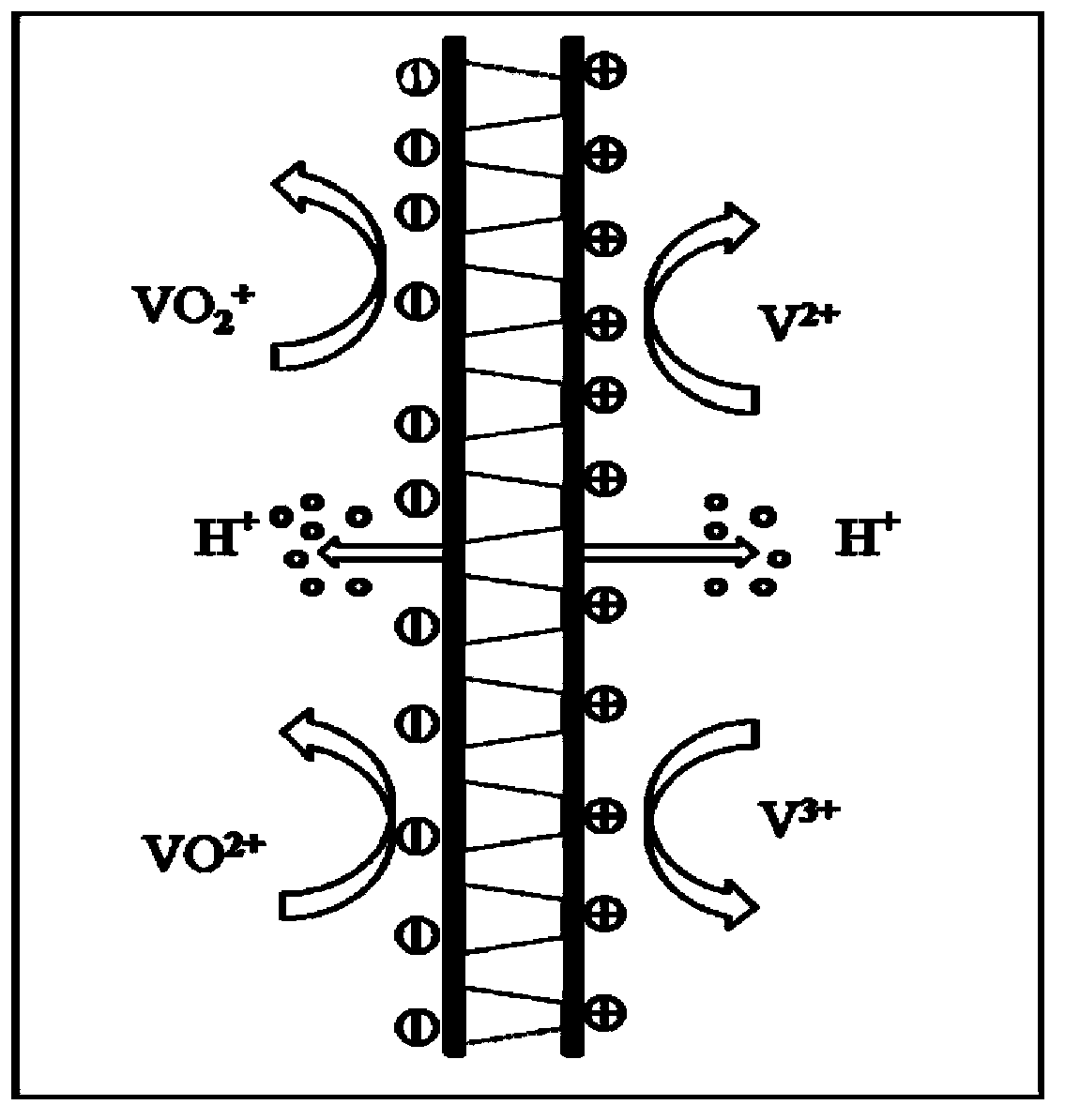

A porous membrane and dual-function technology, which is applied in the field of composite membrane materials for flow batteries, can solve the problems of low vanadium permeability and poor oxidation resistance, and achieve the effects of environmental protection, capacity decay, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

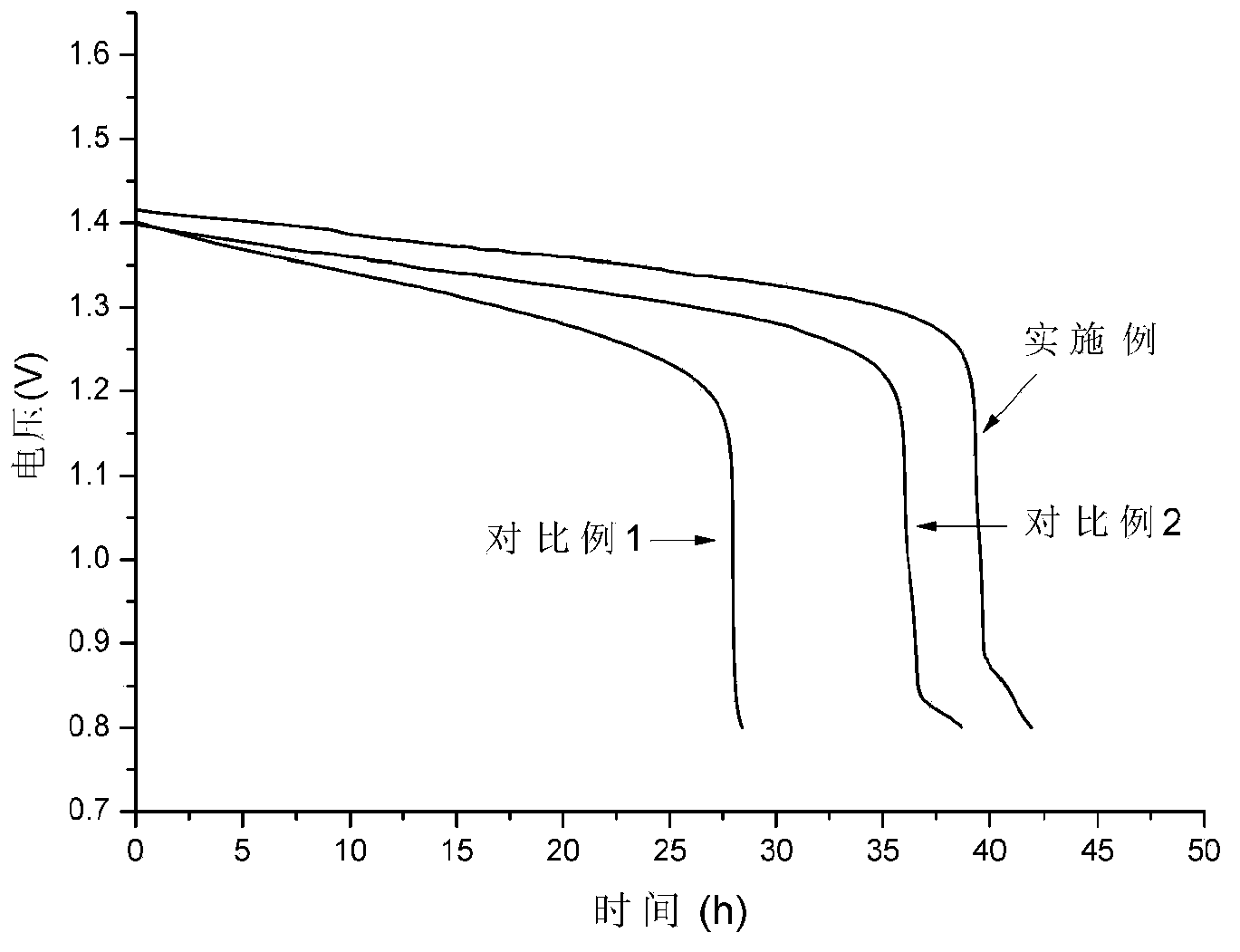

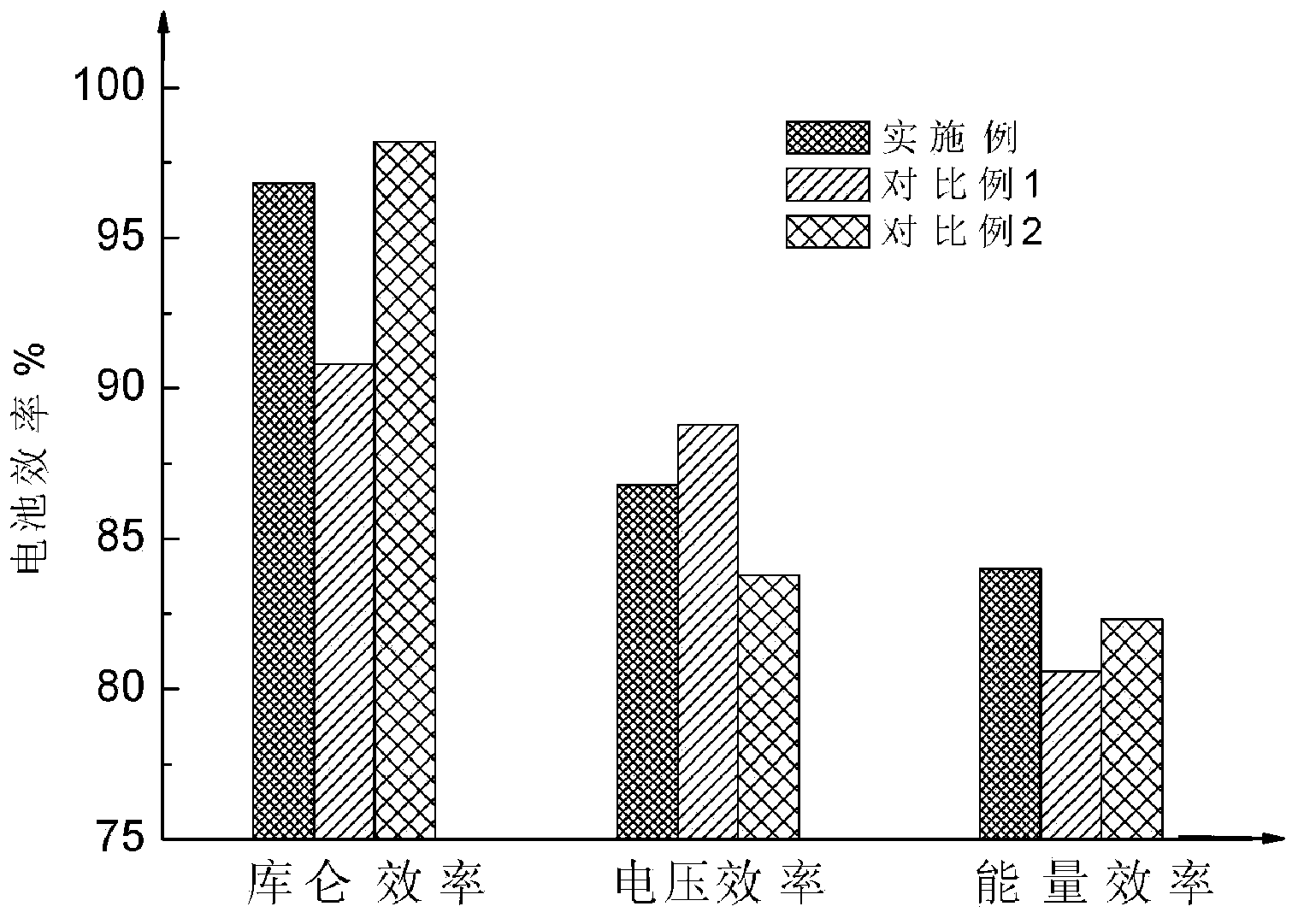

Examples

Embodiment 1

[0051] Dissolve 3g of polyetheretherketone in 29.58ml of DMAc. After the sulfonated polyether ether ketone is completely dissolved, add 12g of polyether ether sulfone and stir for 12 hours until a transparent and uniform polymer solution is formed; stop stirring and let it stand for 4 hours. Degassing on a hot stage at a temperature of 40°C. Then the polymer solution was scraped onto the surface of the glass plate with a spatula to form a primary film with a thickness of about 200 μm, which was quickly immersed in 5 L of water and cured to form a porous diaphragm. Soak it in deionized water for 2 hours to prepare a porous membrane matrix with a thickness of about 125-130 μm.

[0052] The prepared porous membrane was cleaned, soaked in ethanol for 2 hours, the water therein was replaced, and placed on a hot stage at 40° C. until a porous membrane with a relatively dry surface was obtained.

[0053] Prepare an aqueous imidazole solution with a concentration of 1.0mol / L, immerse...

Embodiment 2

[0056] Embodiment 2: other conditions are the same, polyethersulfone is replaced by polyether ether ketone.

Embodiment 3

[0057] Embodiment 3: other conditions are the same, polyethersulfone is replaced by polyacrylonitrile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com