A differential ion mobility spectrum of a micro-ionization spray ion source and an application method thereof

A differential ion migration and ion source technology, applied in particle separation tubes, ion sources/guns, parts of particle separator tubes, etc., can solve the problems of inability to obtain, good signal strength, etc., and achieve easy technology promotion, good Repeatability and stability, the effect of avoiding bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

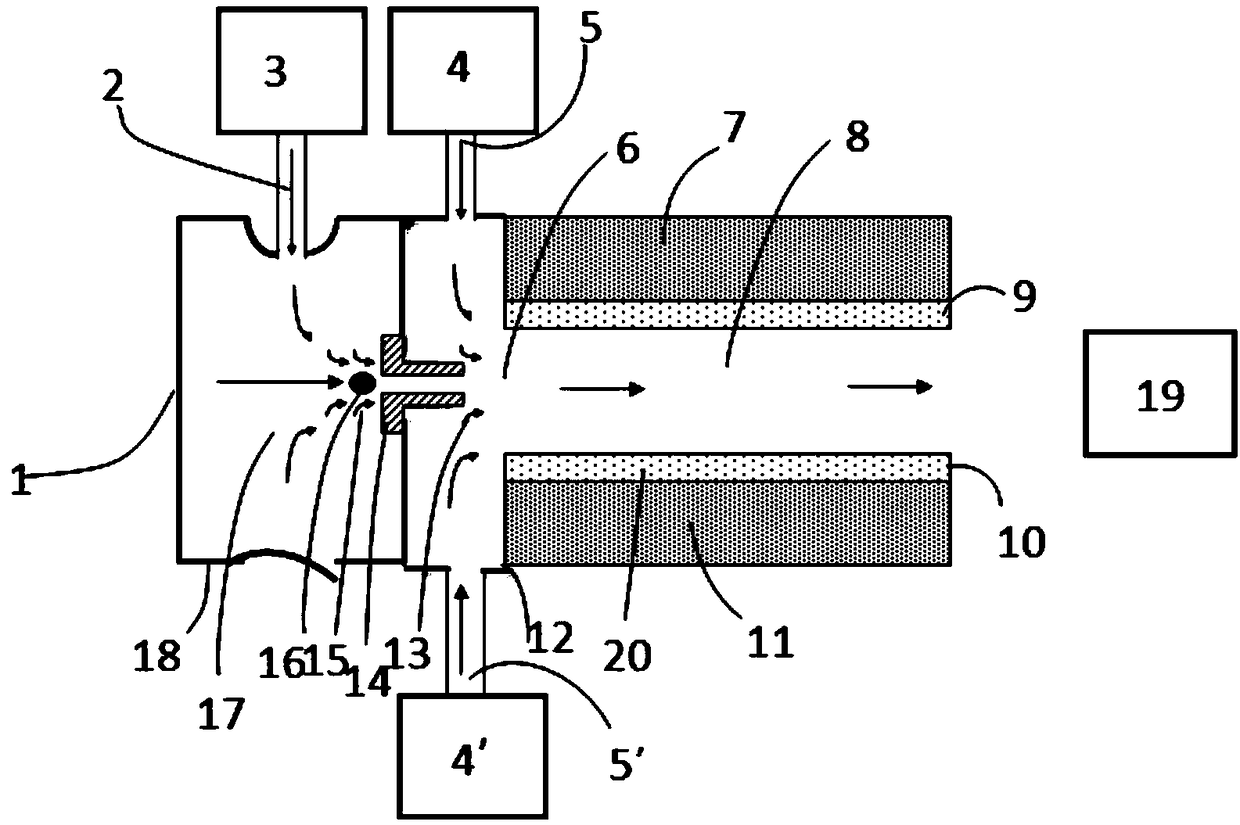

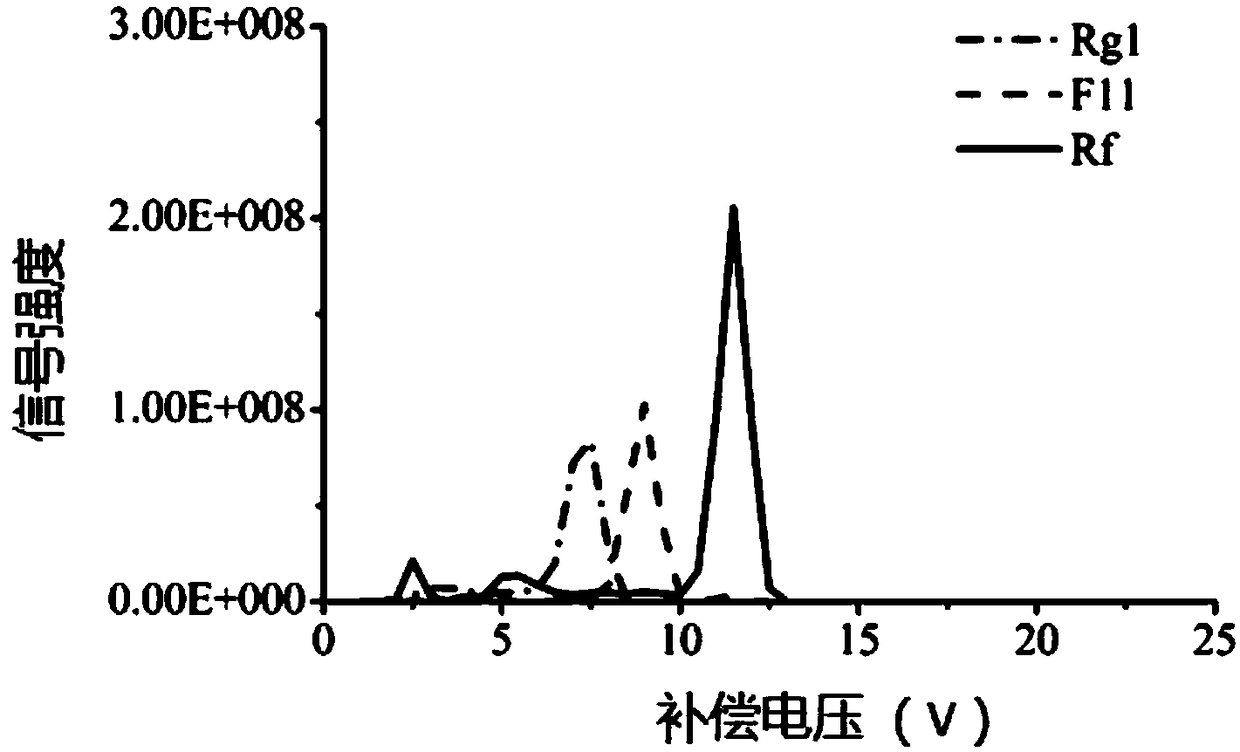

[0041] use figure 1 The mESI-DMS device shown has a plate height of 1.4 mm, a plate length of 8 cm, a width of 2 cm, a mass spectrometer inlet inner diameter of 2 mm, a fused silica capillary inner diameter of 20 microns and an outer diameter of 250 microns, electrospray The high voltage of the ion source is 1.5 kV, and ginsenoside Rg1, Rf and pseudo-ginsenoside F11 are used as analysis samples. These three samples are isomers, and the solution flow rate is 30 microliters per hour. Sodium acetate is added to the samples to assist A sodium peak is formed. The flow rates of the auxiliary gathering gas and auxiliary atomizing gas are set to 600 ml per minute, 99.999% nitrogen is used as the carrier gas, and the temperature is room temperature. 0.1% (molar ratio) of n-propanol is added to the carrier gas as an organic solvent modifier to improve the separation performance of DMS. The DMS is applied with a high-field asymmetric waveform high-frequency voltage with a peak-to-peak vo...

Embodiment 2

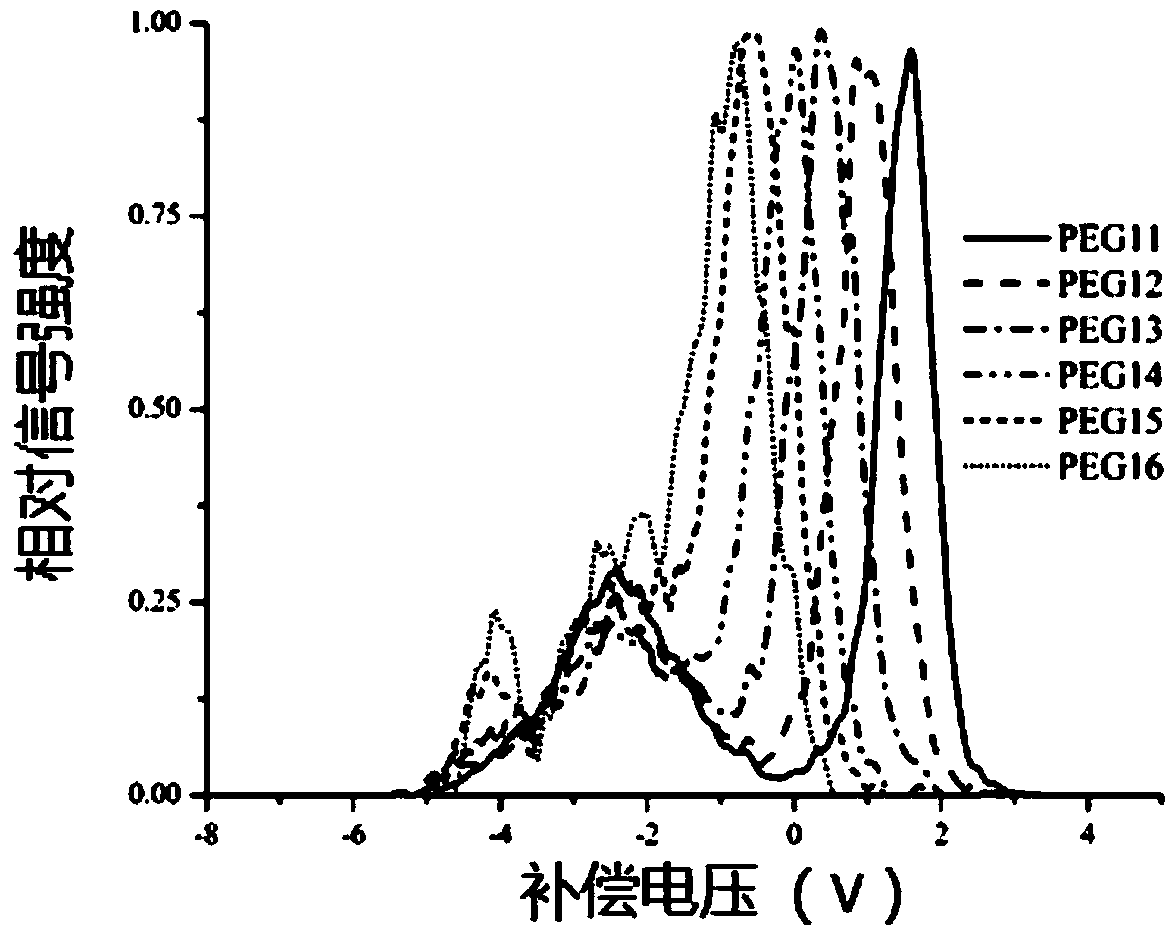

[0044] use figure 1 The mESI-DMS device shown has a plate height of 1.4 mm, a plate length of 8 cm, a width of 2 cm, a mass spectrometer inlet inner diameter of 1 mm, a fused silica capillary with an inner diameter of 50 microns and an outer diameter of 250 microns, electrospray The high voltage of the ion source is 3 kV, polyethylene glycol polymer is used as the analysis sample, and the solution flow rate is 30 microliters per hour. The flow rates of the auxiliary gathering gas and auxiliary atomizing gas are set to 600 ml per minute, 99.999% nitrogen is used as the carrier gas, and the temperature is room temperature. No organic solvent modifier is added to the carrier gas; the DMS is applied with a high-field asymmetric waveform high-frequency voltage with a peak-to-peak voltage of 6 kV; the mass spectrometer inlet is grounded to effectively attract the sample ions migrated from the DMS into the ions In the channel.

[0045] The experimental result is image 3 As shown, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com