Electrolyte solution for lithium sulfur battery

A technology of electrolyte solution and lithium-sulfur battery, applied in the direction of lithium batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve problems such as inability to meet practical requirements, achieve good stability and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

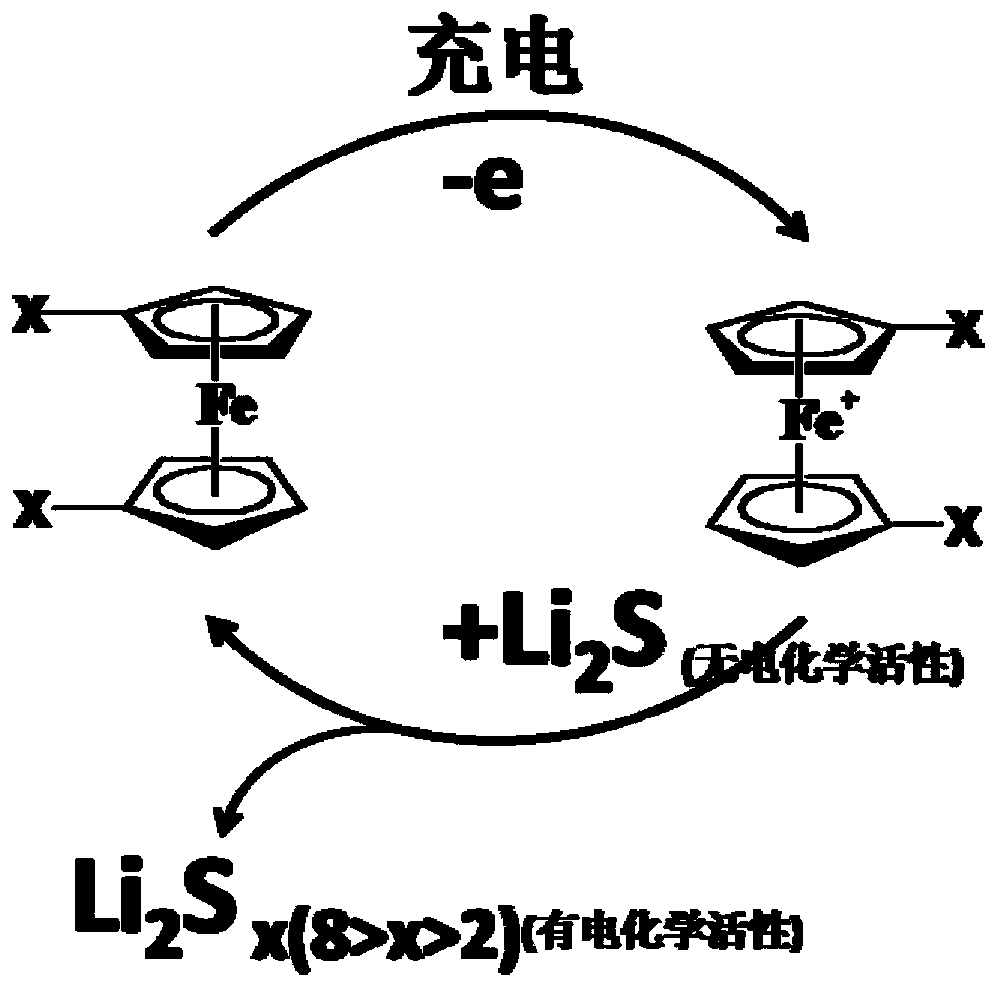

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Electrolyte solution preparation: Conductive salt 0.025mol LiN(SO 3 CF 3 ) 2 and 0.136g of ferrocene were added to a mixed solvent of 12.5ml of ethylene glycol dimethyl ether and 12.5ml of dioxolane, stirred and dissolved, and sealed for use.

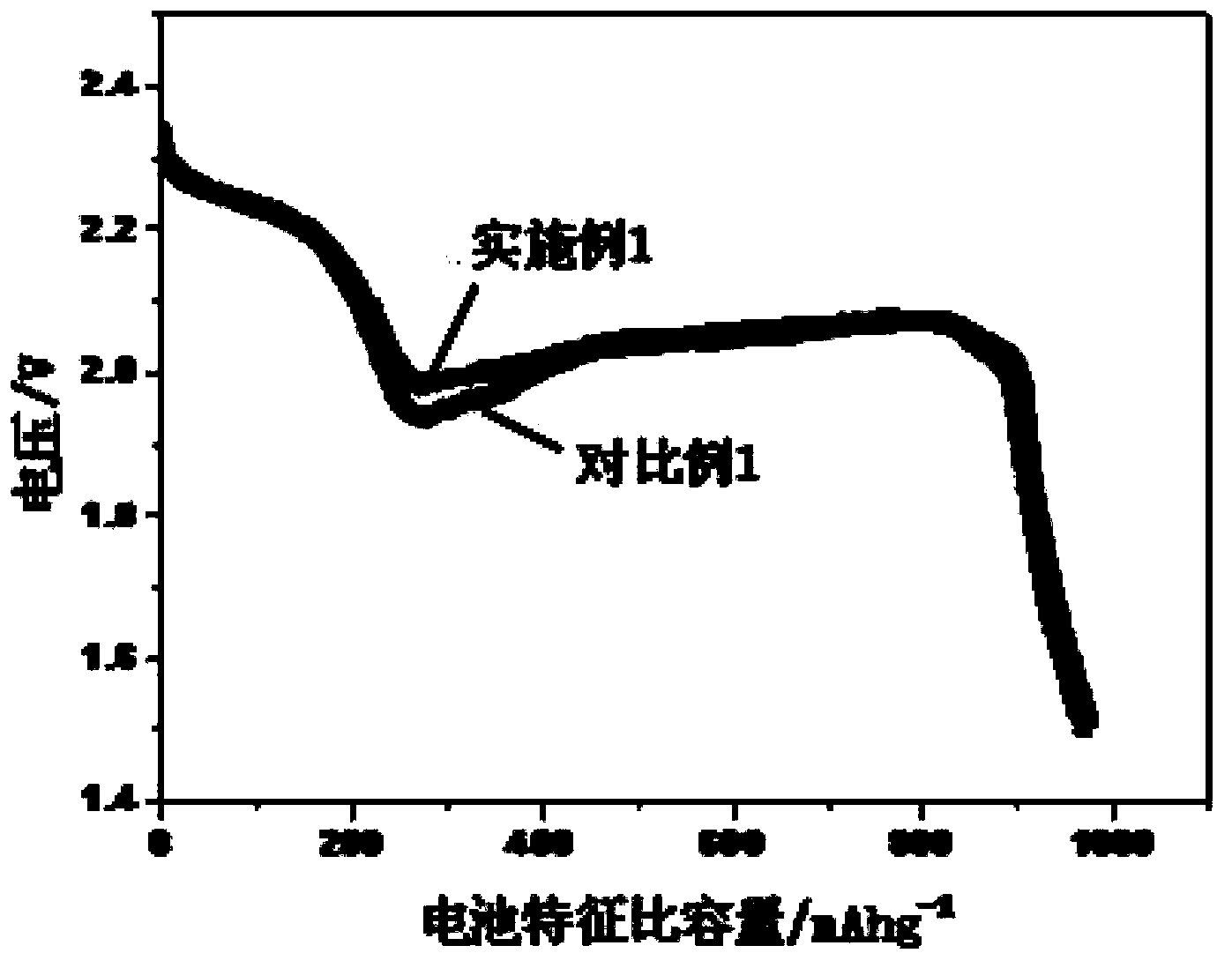

[0033] The prepared electrolyte solution was tested for lithium-sulfur battery.

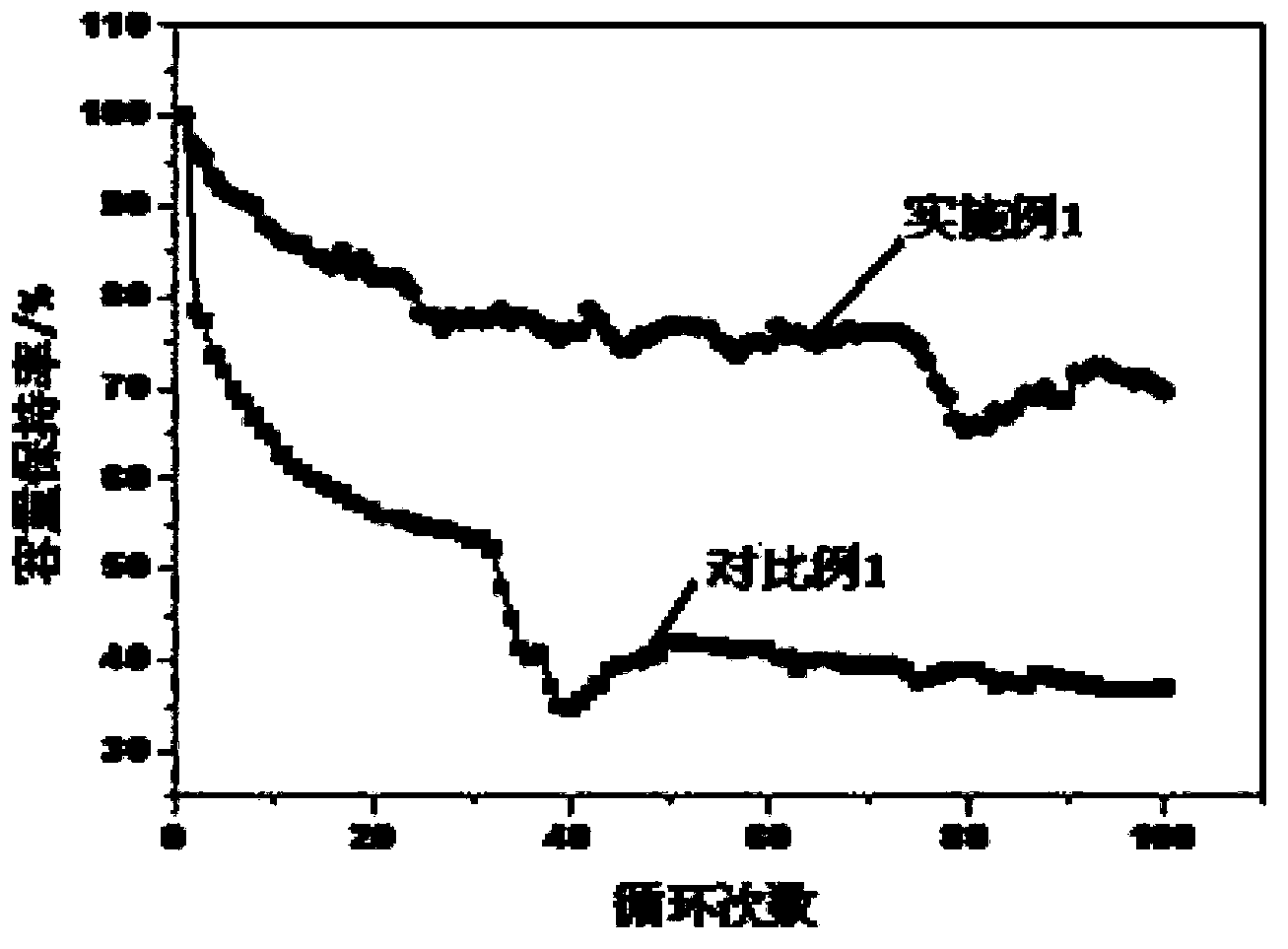

[0034] The battery test method is as follows: the negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 20 microns, and the positive electrode is prepared by the following method: 30 parts by mass of AB carbon, 60 parts by mass of elemental sulfur, and 10 parts by mass of polyvinylidene fluoride (PVDF) blended in N-methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The above-mentioned components were assembled together in a layered structure of positive electrode / diaphragm / negative electrode, and sealed after adding electrolyt...

Embodiment 2

[0040] Electrolyte solution preparation: Conductive salt 0.025molLiN(SO 3 CF 2 CF 3 ) 2 and 0.15g lithium ferrocenemethoxide was added to 20ml triethylene glycol dimethyl ether (CH 3 O(CH 2 CH 2 O) 3 CH 3 ) and 5ml of dioxolane in a mixed solvent, stirred and dissolved, and sealed for later use. The prepared electrolyte solution was tested for lithium-sulfur battery. The battery testing method is the same as in Example 1. After 100 cycles, the capacity retention rate is shown in Table 1.

Embodiment 3

[0042] Electrolyte solution preparation: Conductive salt 0.05mol LiN(SO 3 CF 2 CF 3 ) 2and 0.2g of 1,1'-lithium ferrocenedimethoxide was added to 12.5ml of ethylene glycol diethyl ether (CH 3 CH 2 OCH 2 CH 2 OCH 2 CH 3 ) and 12.5ml of dioxane in a mixed solvent, stirred and dissolved, and sealed for later use. The prepared electrolyte solution was tested for lithium-sulfur battery. The battery testing method is the same as in Example 1. After 100 cycles, the capacity retention rate is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com