Method for manufacturing gallium arsenide laser capable of lowering electron leakage

A technology of electron leakage and manufacturing method, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve problems such as electron leakage, and achieve the effect of reducing electron leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

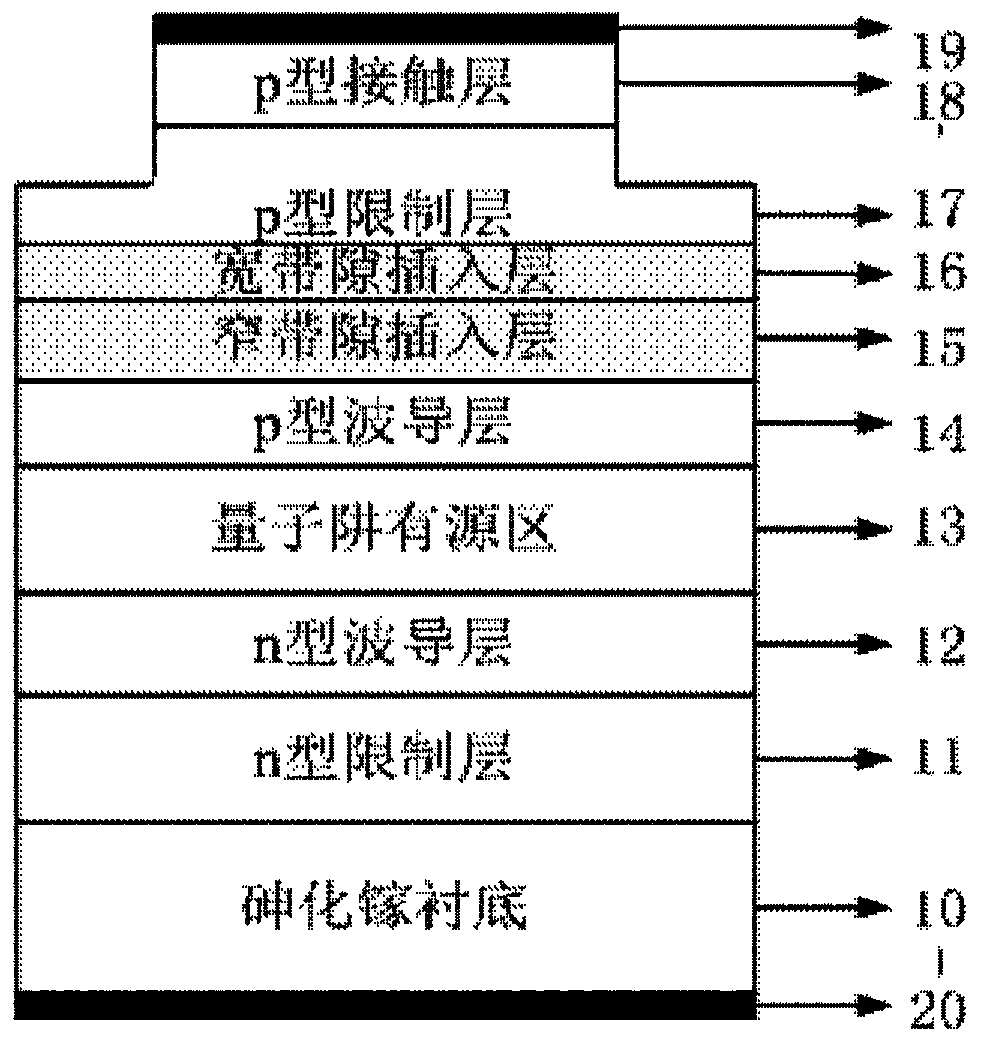

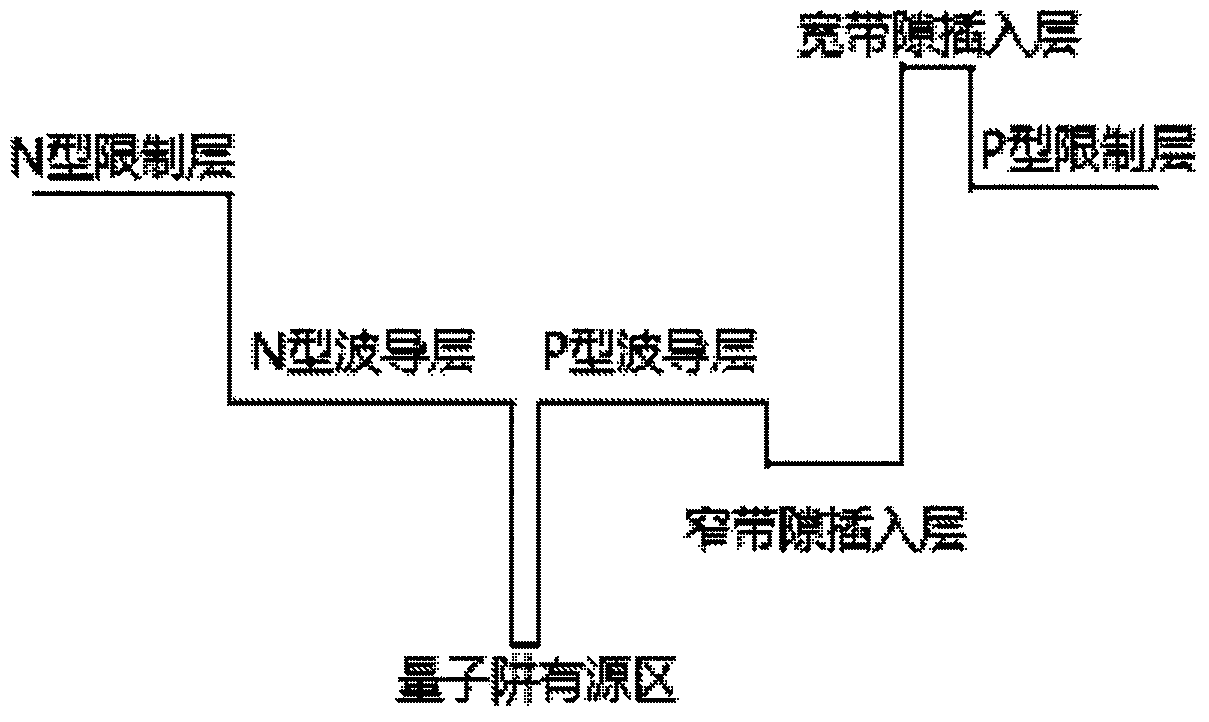

[0017] see figure 1 As shown, the present invention provides a method for manufacturing a gallium arsenide laser with reduced electron leakage, which includes the following steps.

[0018] Step 1: Epitaxially grow N-type confinement layer 11, N-type waveguide layer 12, quantum well active region 13, P-type waveguide layer 14, narrow-bandgap insertion layer 15, wide-bandgap insertion layer 16, P-type confinement layer 17 and P-type contact layer 18 .

[0019] Step 2: Etch the P-type contact layer 18 and the P-type confinement layer 17 into a ridge shape by wet etching or dry etching. The wet etching operation is relatively simple and can be used when the etching depth is not very deep, but it is easy to cause undercutting and has a great impact on the device. If the corrosion depth is very deep, it is best to use dry etching such as ICP.

[0020] Step 3: growing a layer of oxide mold on the ridge-shaped surface, and using photolithography to form a P-type ohmic electrode 19 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com