Membrane-Based Method for Selective Fractionation of Essential Oils

A technology selected from essential oils, applied in essential oils/fragrances, chemical instruments and methods, membrane technology, etc., can solve the problems of lengthy separation, heat sensitivity, etc., save time and energy, have good dewaxing performance, and save method steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

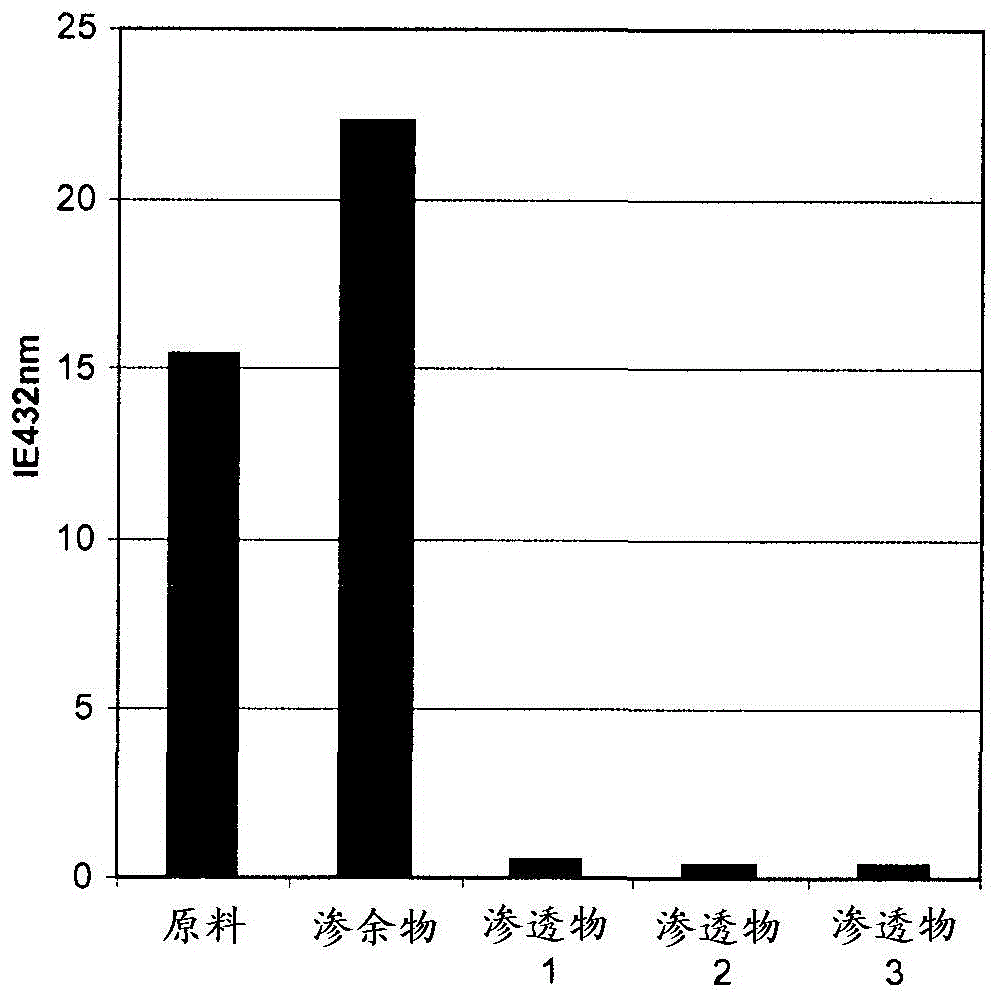

[0122] Example 1 - Decolorization from Single Orange Oil

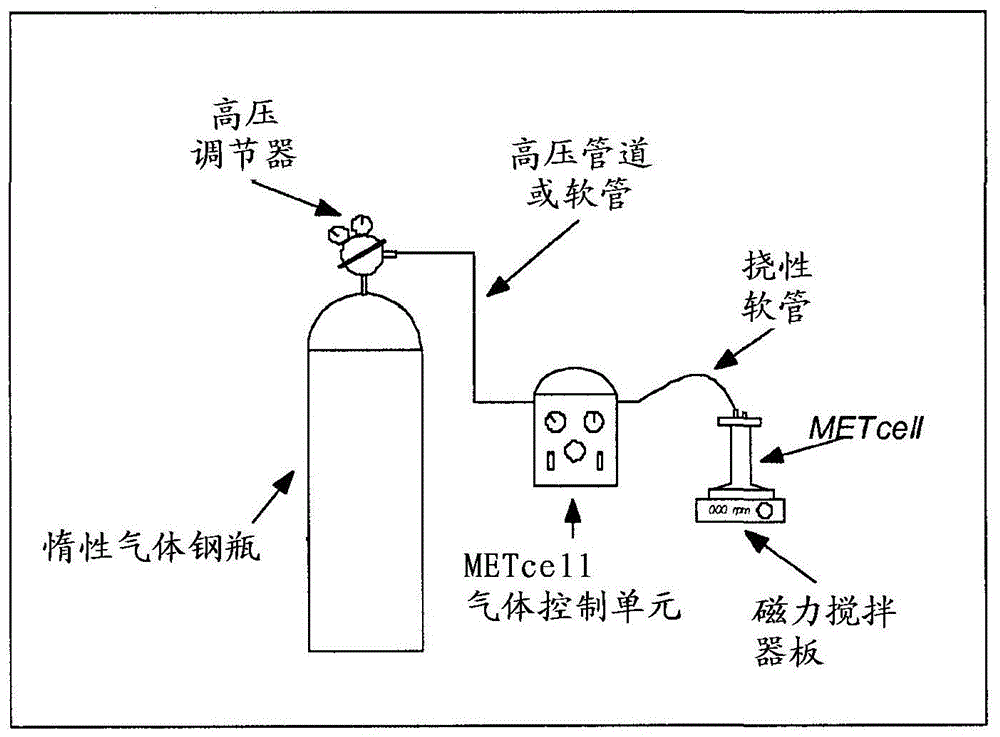

[0123] will contain PuraMem TM A dead-end METcell filter tank (Evonik Membrane Extraction Technology Ltd., UK) of S380 organic solvent nanofiltration membrane (Evonik Membrane Extraction Technology Ltd., UK) specimen was used for this experiment - for a schematic diagram of the METcell dead-end filtration system, see Figure 1 . PuraMem TM S380 is prepared according to DE10 2009 047 351 with 600 g.mol -1 Nominal molecular weight cut-offs for silicone-coated membranes. PuraMem was obtained by filtering 200 mL of limonene (Sigma-Aldrich, Germany) at ambient temperature and 30 bar filtration pressure. TM S380 Membrane is stripped of conditioner (preservative) making the membrane ready for use.

[0124] Once the membrane was prepared, the filter tank was emptied and refilled with 100 mL single orange oil. The single orange oil was filtered at a temperature of 30°C and a filtration pressure of 30 bar. 75 mL of oil w...

Embodiment 3

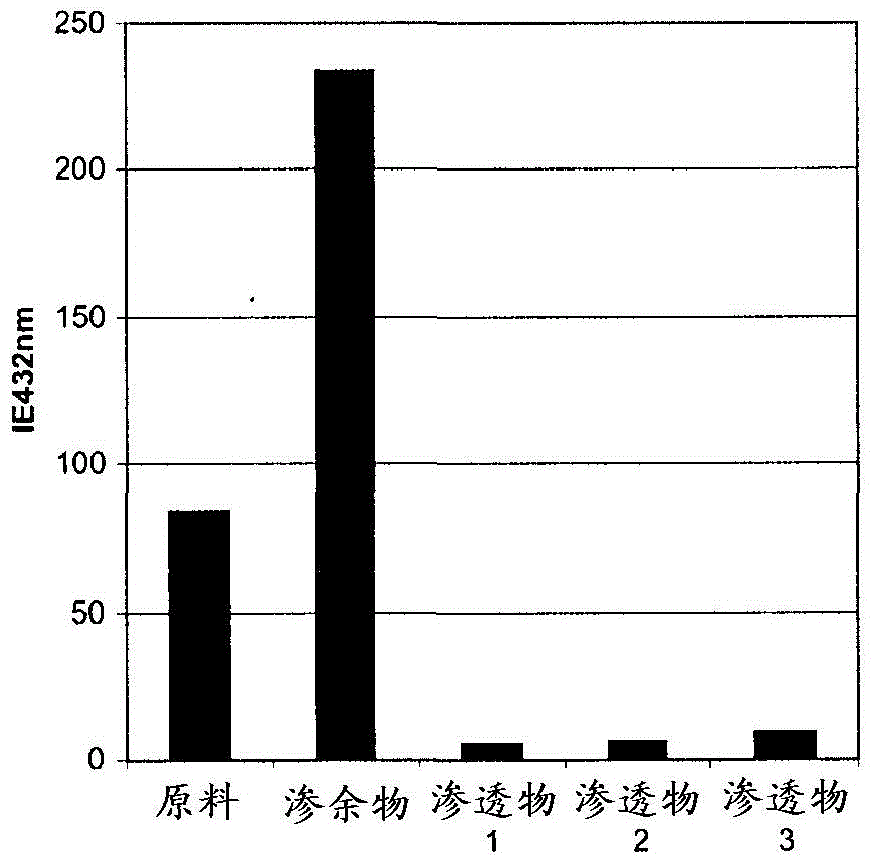

[0130] Example 3 - Removal of Natural Impurities (Waxes) from Orange Oil

[0131] will contain PuraMem TM A dead-end METcell filter tank (Evonik Membrane Extraction Technology Ltd., UK) of S380 organic solvent nanofiltration membrane (Evonik Membrane Extraction Technology Ltd., UK) specimen was used for this experiment - for a schematic diagram of the METcell dead-end filtration system, see Figure 1 . PuraMem TM S380 is prepared according to DE10 2009 047 351 with 600 g.mol -1 Nominal molecular weight cut-offs for silicone-coated membranes. PuraMem was obtained by filtering 200 mL of limonene (Sigma-Aldrich, Germany) at ambient temperature and 30 bar filtration pressure. TM S380 Membrane is stripped of conditioner (preservative) making the membrane ready for use.

[0132] Once the membrane was prepared, the filter tank was emptied and refilled with 100 mL of five times orange oil. The fivefold orange oil was filtered at a temperature of 30°C and a filtration pressure o...

Embodiment 4

[0134] Example 4 - Fractionation of Components in Single Orange Oil

[0135] will contain DuraMem TM A METcell cross-flow filtration system (Evonik Membrane Extraction Technology Ltd, UK) of the S XP2 organic solvent nanofiltration membrane (Evonik Membrane Extraction Technology Ltd.) test piece was used for this experiment - see Figure 5 for a schematic diagram of the METcell cross-flow filtration system. DuraMem TM S XP2 is prepared according to DE10 2009 047 351 with about 350 g.mol -1 Nominal molecular weight cut-offs for silicone-coated membranes. DuraMem was obtained by filtering 200 mL of limonene (Sigma-Aldrich, Germany) through the membrane coupon at ambient temperature and 30 bar filtration pressure. TM S XP2 membranes were stripped of conditioners (preservatives) making the membranes ready for use.

[0136] Once the membrane is prepared, the filter tank is emptied and filled with 500 mL of PuraMem TM The S380 membrane was processed according to the method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com