Vertical vacuum rolling and kneading machine

A vacuum tumbler and vertical technology, applied in the field of tumbler, can solve the problems of large floor space, unfavorable business expansion and high investment cost, and achieve the effect of reducing floor space, improving work efficiency and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

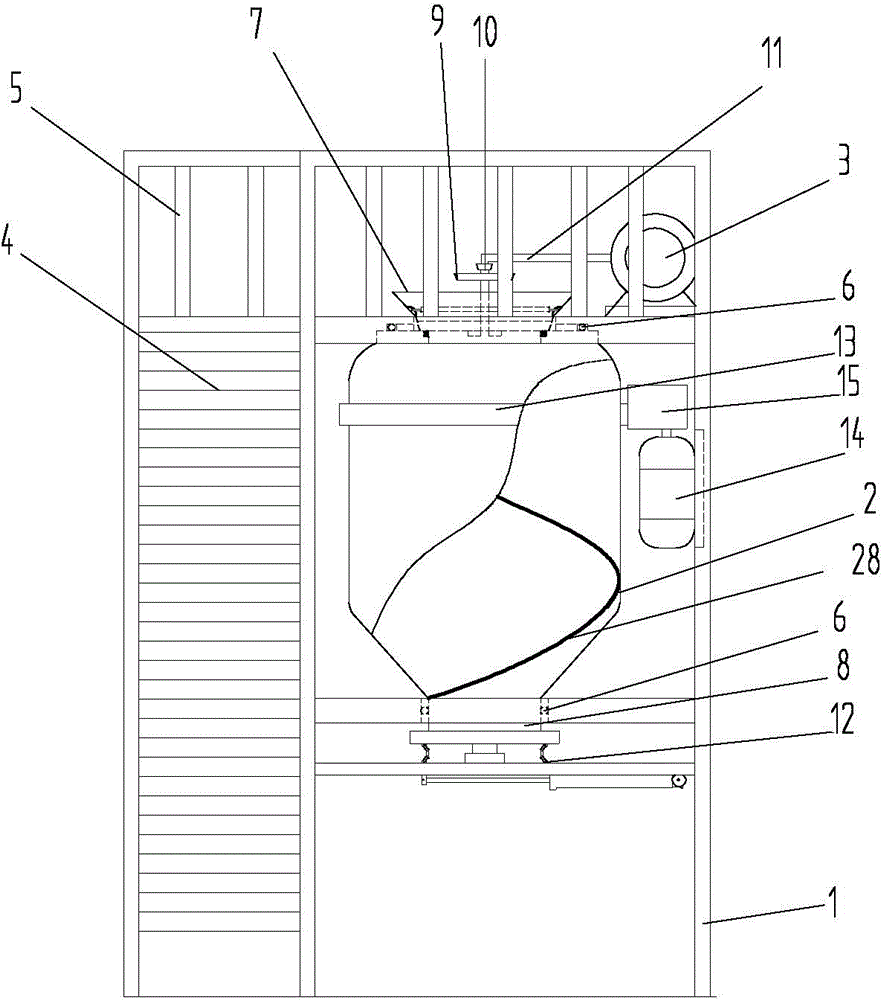

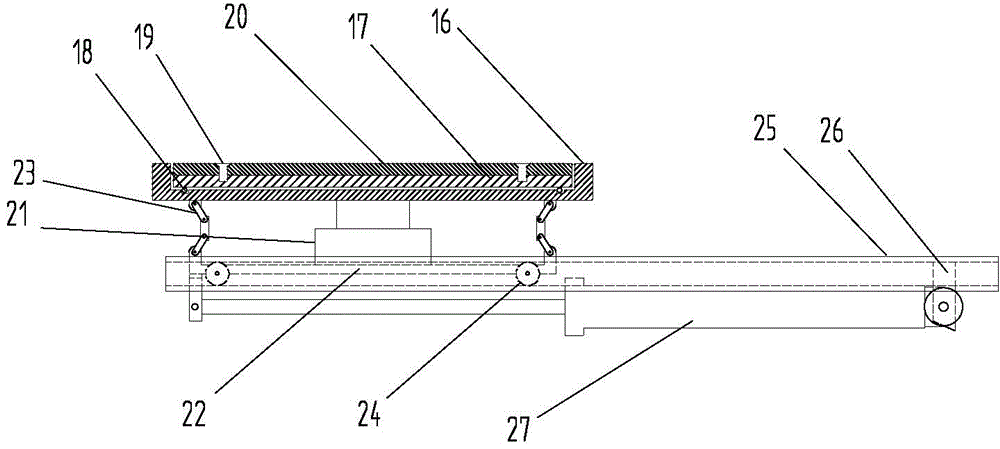

[0013] Such as figure 1 , 2 As shown, the present invention comprises a frame 1, a rotating barrel 2, a vacuum pump 3, a ladder 4 is provided on one side of the frame 1, a guardrail 5 is provided above the frame 1, and a rotating barrel 2 is arranged on the upper part of the frame 1, The upper and lower ends of the rotary material cylinder 2 are connected with the frame 1 through bearings 6, the top of the rotary material cylinder 2 is provided with a feed port 7, the bottom is provided with a discharge port 8, the feed port 7 is provided with a sealing cover door 9, and the feed port 7 One side is provided with a vacuum pump 3 fixed on the frame 1, the airtight cover door 9 is provided with an air pipe 10, the air pipe 10 is connected with the vacuum pump 3 through a hose 11, and a lower cover device 12 is provided below the discharge port 8, and the rotating There is a toothed flange 13 on the outside of the barrel 2, and a motor 14 is provided on the frame 1 on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com