Krypton, xenon gas purification method and device

A gas purification device and gas purification technology, which are applied in specific gas purification/separation, inert gas compounds, chemical instruments and methods, etc., can solve the problem that the service life is only 3 to 6 months, the valve core is abnormally worn, and the system is affected. problems such as normal operation, to achieve the effect of reliable performance, long service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

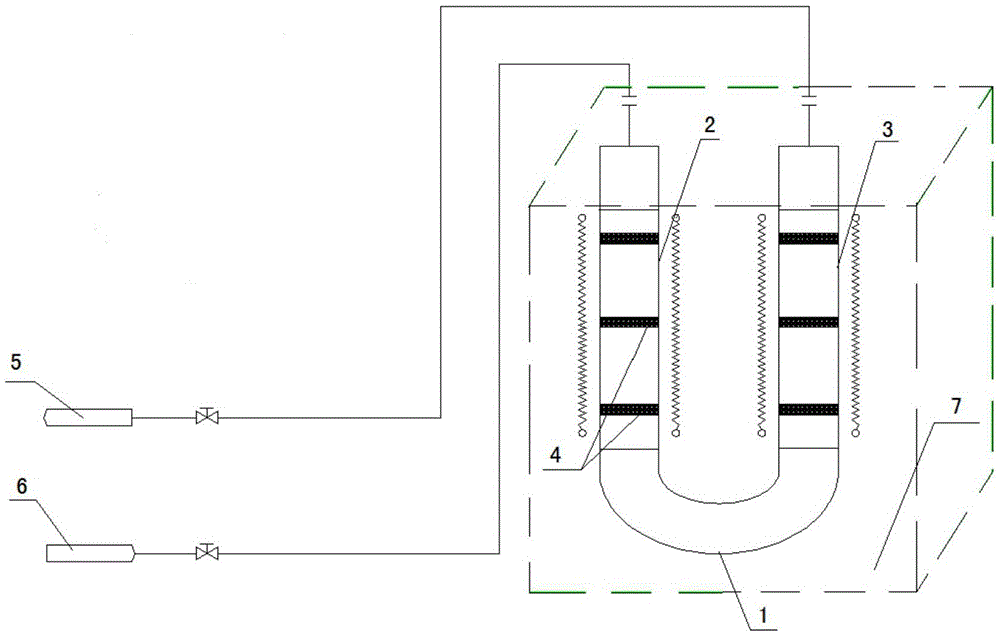

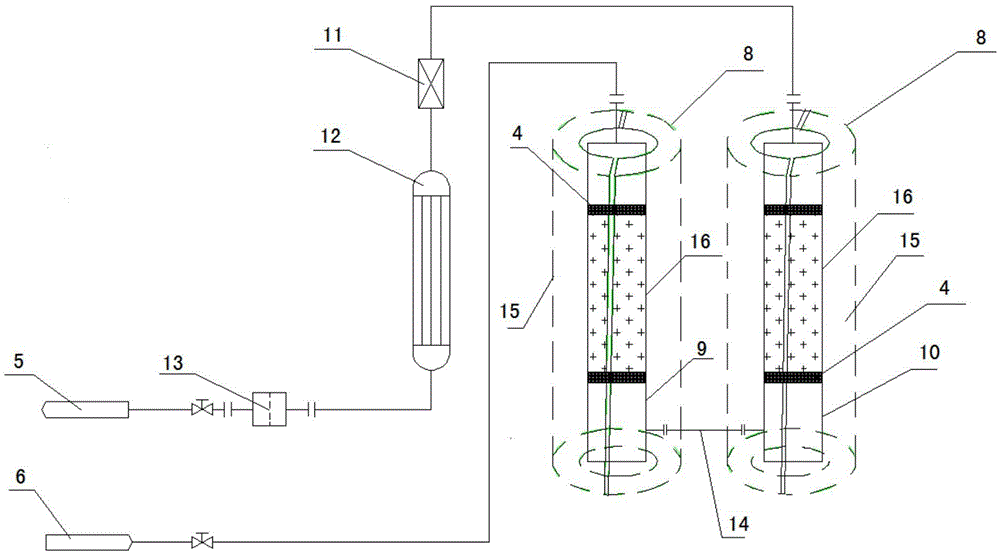

[0037] Below in conjunction with accompanying drawing for further explanation:

[0038] see figure 2 , the original gas cylinder 6, one-stage reaction tube 9, two-stage reaction tube 10, hydrogen adsorber 11, cooler 12 precision filter 13 and product gas cylinder 5 are connected in sequence, and the two-stage reaction tubes 9 and 10 connected in series Use the steel pipe 14 to carry out ferrule type connection between them. Since the steel pipe 14 is detachably connected to the reaction tubes at both ends, the reaction tube can be removed when the first section of the reaction tube 9 fails, and the second section of the reaction tube 10 can be moved forward to be used as a section of the reaction tube 9, and then a new reaction tube can be installed. The tube is used as a two-stage reaction tube 10 without discarding the two reaction tubes together, thereby achieving the purpose of maximizing the use of expensive multi-element alloy getters and reducing operating costs.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com