A glass-ceramic material with ultra-broadband near-infrared luminescence and its preparation method

A glass-ceramic and near-infrared technology, applied in the field of ultra-broadband luminescent materials, can solve problems such as uneven gain, difficulty in ultra-broadband near-infrared light emission, and small bandwidth expansion, so as to increase bandwidth parameters, improve information transmission capabilities, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the steps of preparing glass-ceramic by high-temperature melting method and heat treatment method are as follows:

[0037] (1) Select high-purity Li 2 CO 3 , SiO 2 、Al 2 o 3 、 Ta 2 o 5 , NiO as raw materials, the molar ratio between raw materials is controlled as Li2 CO 3 : SiO 2 :Al 2 o 3 : Ta 2 o 5 : NiO=20:30:30:20:0.2;

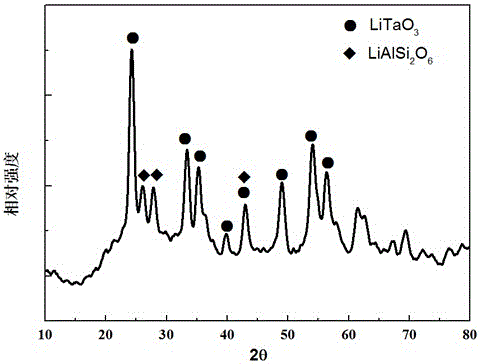

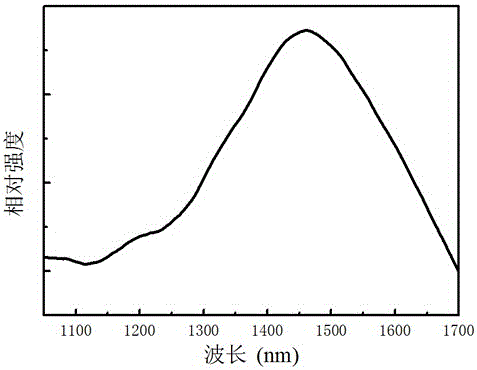

[0038] (2) Weigh a total of 40 grams of raw materials according to the ratio of step (1), grind them in an agate grinding body for 40 minutes, and then put them into a platinum crucible and keep them warm at 1600°C for 2 hours. The melted glass solution was poured on a copper plate and flattened with another copper plate, then transferred to a muffle furnace and kept at 500°C for 5 hours, then the power of the muffle furnace was turned off, and the glass was allowed to cool down to room temperature with the furnace to obtain Glass brown in color. Put the glass into the muffle furnace, raise the temperature from room te...

Embodiment 2

[0043] In this example, the steps of preparing glass-ceramic by high-temperature melting method and heat treatment method are as follows:

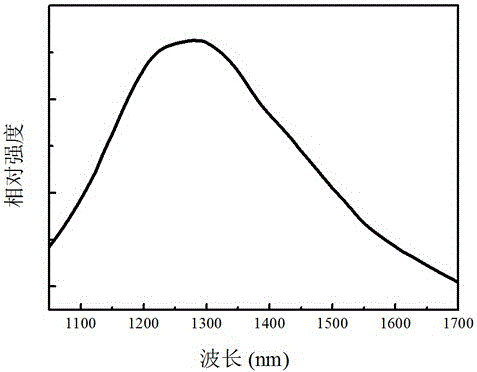

[0044] (1) Select high-purity Li 2 CO 3 , SiO 2 、Al 2 o 3 , Nb 2 o 5 , NiO as raw materials, the molar ratio between raw materials is controlled as Li 2 CO 3 : SiO 2 :Al 2 o 3 : Nb 2 o 5 :NiO=25:35:15:25:1;

[0045] (2) Weigh a total of 40 grams of raw materials according to the ratio of step (1), grind them in an agate grinder for 40 minutes, and then put them into a platinum crucible and keep them warm at 1650°C for 2 hours. The melted glass solution was poured on a copper plate and flattened with another copper plate, then transferred to a muffle furnace and kept at 500°C for 5 hours, then the power of the muffle furnace was turned off, and the glass was allowed to cool down to room temperature with the furnace to obtain Glass brown in color. Put the glass into the muffle furnace, raise the temperature from room temperatu...

Embodiment 3

[0047] (1) Select high-purity Li 2 CO 3 , SiO 2 、Al 2 o 3 、 Ta 2 o 5 , NiO as raw materials, the molar ratio between raw materials is controlled as Li 2 CO 3 : SiO 2 :Al 2 o 3 : Ta 2 o 5 : NiO=20:30:30:20:0.2;

[0048] (2) Weigh a total of 40 grams of raw materials according to the ratio of step (1), grind them in an agate grinding body for 40 minutes, and then put them into a platinum crucible and keep them warm at 1600°C for 2 hours. The melted glass solution was poured on a copper plate and flattened with another copper plate, then transferred to a muffle furnace and kept at 500°C for 5 hours, then the power of the muffle furnace was turned off, and the glass was allowed to cool down to room temperature with the furnace to obtain Glass brown in color. Put the glass into the muffle furnace, raise the temperature from room temperature to 1000°C at a rate of 300°C / h, keep it warm for 10 hours, then turn off the power of the muffle furnace and let the glass cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com