A magnetic Fe3O4 nano-particle/flake aluminium pigment composite nanometer material

A composite nanomaterial and nanoparticle technology, which is applied in the field of Fe3O4 nanoparticle/flaky aluminum pigment composite nanomaterials, can solve the problems that aluminum pigments are not magnetic and cannot actively respond to magnetic fields, so as to achieve difficult agglomeration, uniform dispersion and magnetic field. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

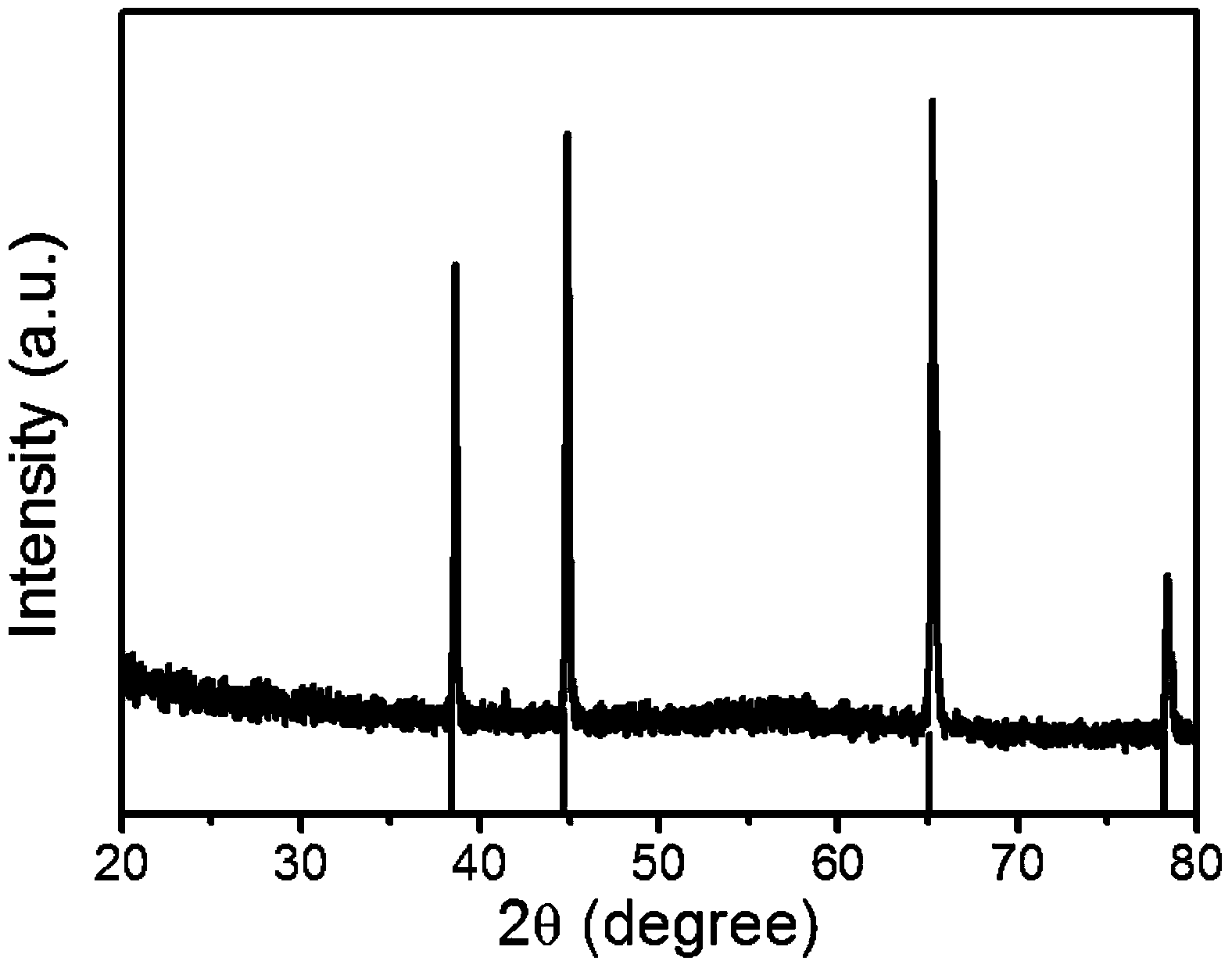

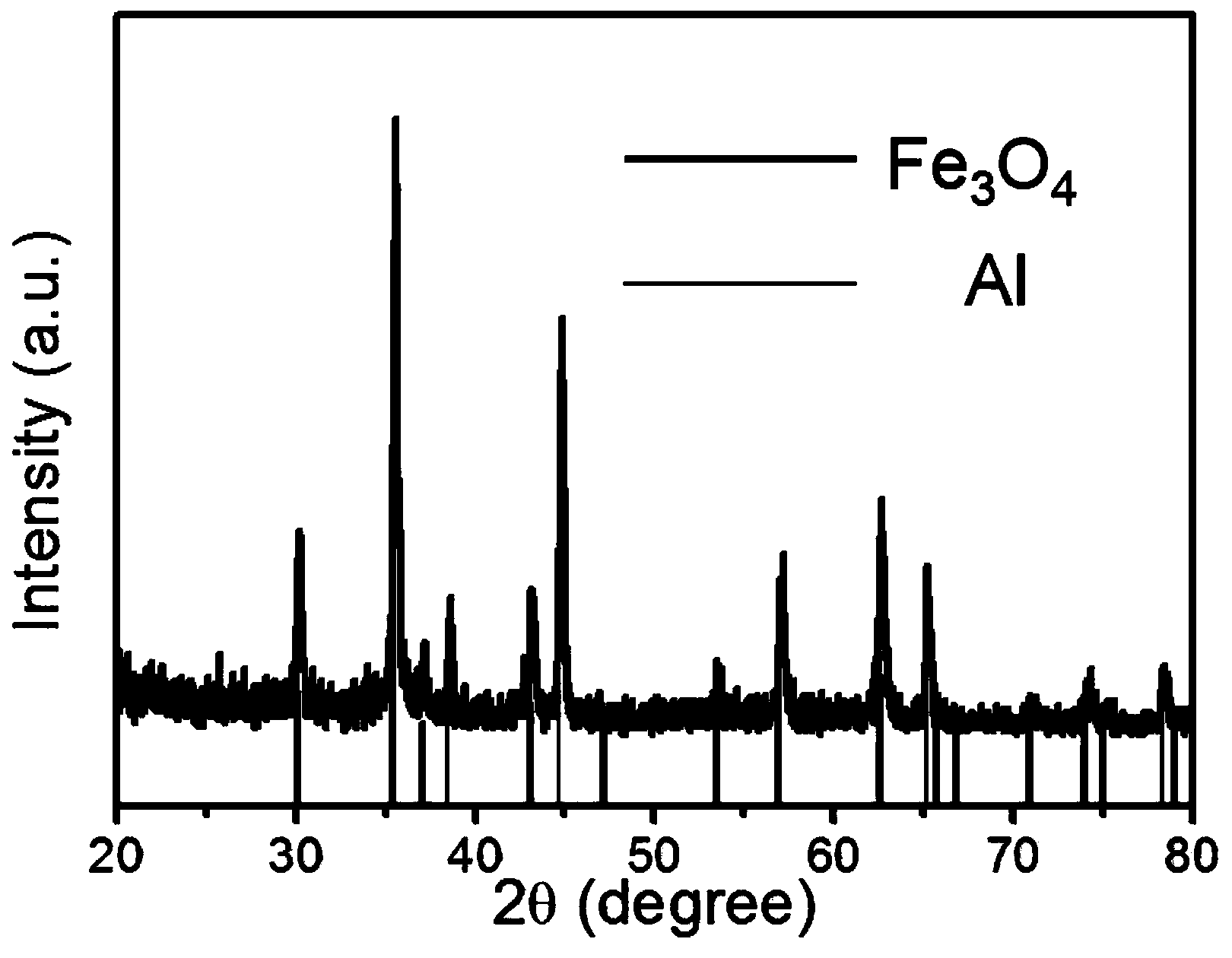

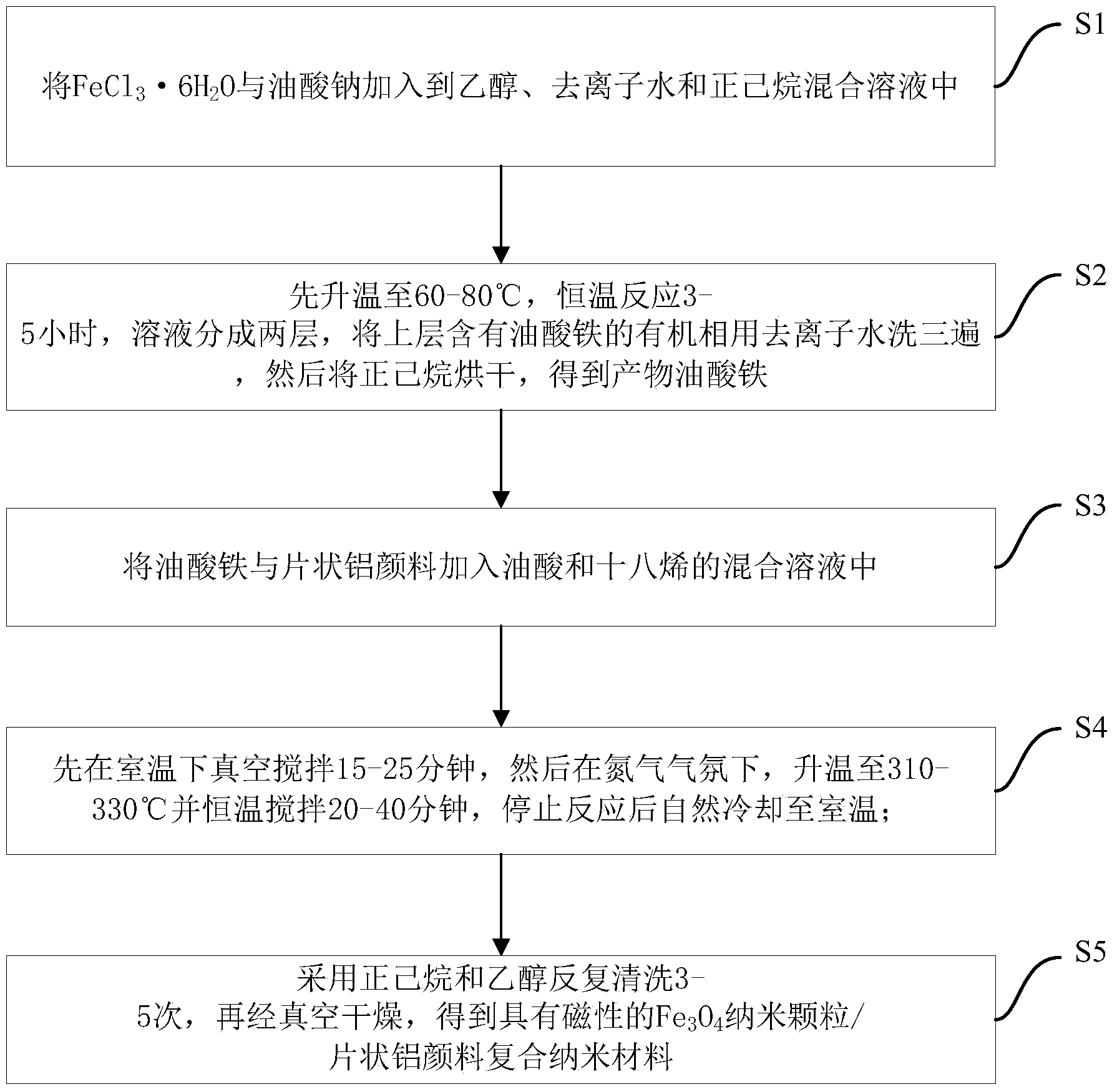

[0033] A magnetic Fe 3 o 4 Nanoparticle / flaky aluminum pigment composite nanomaterials, the FeCl 3 ·6H 2 O and sodium oleate were added to the mixed solution of ethanol, deionized water and n-hexane, wherein the amounts of each raw material were: FeCl 3 ·6H 2 O: 0.432g, sodium oleate: 1.46g, ethanol: 3.2mL, deionized water: 2.4mL, n-hexane: 5.6mL; first raise the temperature to 70°C, react at constant temperature for 4 hours, the solution is divided into two layers, and the upper layer contains oil The organic phase of acid iron was washed three times with deionized water, and then dried with n-hexane to obtain the product iron oleate; iron oleate and flake aluminum pigment were added to the mixed solution of oleic acid and octadecene, wherein each raw material The amounts are flake aluminum pigment: 20mg, oleic acid: 0.255mL, octadecene: 10.1mL; first stir in vacuum at room temperature for 20 minutes, then raise the temperature to 320°C and stir at constant temperature fo...

Embodiment 2

[0035] A magnetic Fe 3 o 4 Nanoparticle / flaky aluminum pigment composite nanomaterials, the FeCl 3 ·6H 2 O and sodium oleate were added to the mixed solution of ethanol, deionized water and n-hexane, wherein the amounts of each raw material were: FeCl 3 ·6H 2 O: 0.42g, sodium oleate: 1.4g, ethanol: 2.835mL, deionized water: 2.0811mL, n-hexane: 4.914mL; first raise the temperature to 60°C, react at constant temperature for 5 hours, the solution is divided into two layers, and the upper layer contains oil The organic phase of acid iron was washed three times with deionized water, and then dried with n-hexane to obtain the product iron oleate; iron oleate and flake aluminum pigment were added to the mixed solution of oleic acid and octadecene, wherein each raw material The amounts are flake aluminum pigment: 0.018g, oleic acid: 0.231mL, octadecene: 9.303mL; first stir at room temperature in vacuum for 15 minutes, then raise the temperature to 310°C under a nitrogen atmosphere...

Embodiment 3

[0037] A magnetic Fe 3 o 4 Nanoparticle / flaky aluminum pigment composite nanomaterials, the FeCl 3 ·6H 2 O and sodium oleate were added to the mixed solution of ethanol, deionized water and n-hexane, wherein the amounts of each raw material were: FeCl 3 ·6H 2 O: 0.444g, sodium oleate: 1.52g, ethanol: 3.7074mL, deionized water: 2.7417mL, n-hexane: 6.327mL; first raise the temperature to 60°C, react at constant temperature for 5 hours, the solution is divided into two layers, and the upper layer contains oil The organic phase of acid iron was washed three times with deionized water, and then dried with n-hexane to obtain the product iron oleate; iron oleate and flake aluminum pigment were added to the mixed solution of oleic acid and octadecene, wherein each raw material The amounts are flake aluminum pigment: 0.022g, oleic acid: 0.2886mL, octadecene: 11.0445mL; first stir at room temperature in vacuum for 25 minutes, then raise the temperature to 330°C under nitrogen atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com