Anionic surfactant for micro-foam drilling fluid and preparation method thereof

A surfactant and anionic technology, which is applied in the field of oilfield drilling fluid treatment agent synthesis, can solve the problems that it is difficult to ensure the low density of drilling fluid, poor air tightness in microbubbles, and affect the safety of drilling construction, etc., and achieve compression resistance Strong, strong foaming ability, low cycle density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

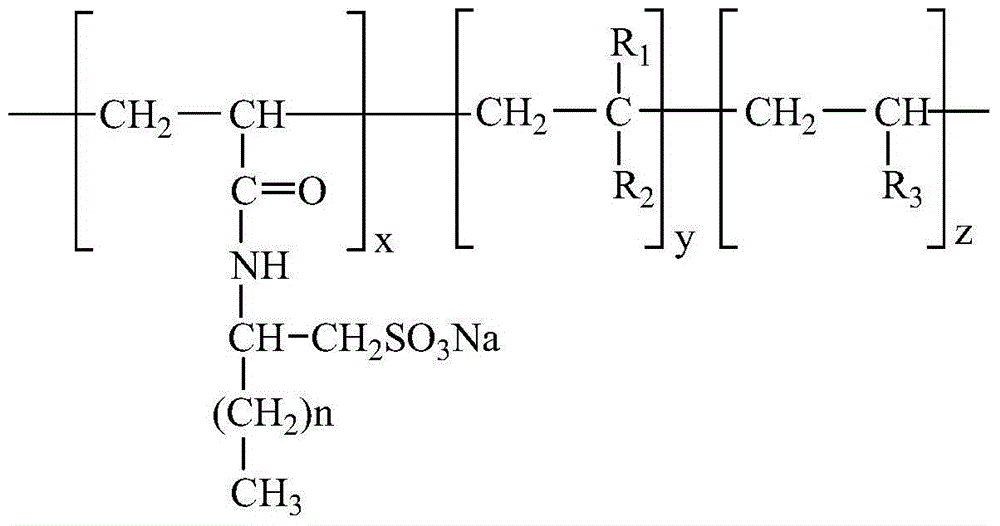

Embodiment 1

[0021] Dissolve 5g of acrylic acid and 25g of 2-acrylamido-2-methylpropanesulfonic acid in 100g of clear water to obtain a mixed reaction monomer solution. For use, dissolve 0.4g of ammonium persulfate in 70g of clear water for use, and add 50g of 2- Acrylamide dodecane sulfonic acid and 0.8g hydroquinone were dissolved in 150g of water and the temperature was raised to 50°C, then the mixed reaction monomer solution and ammonium persulfate solution were added to the reaction system, and then the system was raised to 90°C After reacting for 1 hour, a surfactant product with a solid content of 20% is obtained. After the reaction, the system is neutralized with sodium hydroxide to a pH value of 8, and after drying and crushing, a surface active agent for microbubble drilling fluid with an average molecular weight of 7000 is obtained. The structural formula is:

[0022]

[0023] The amount ratio of x:y:z substances is 3.1:1.4:2.4.

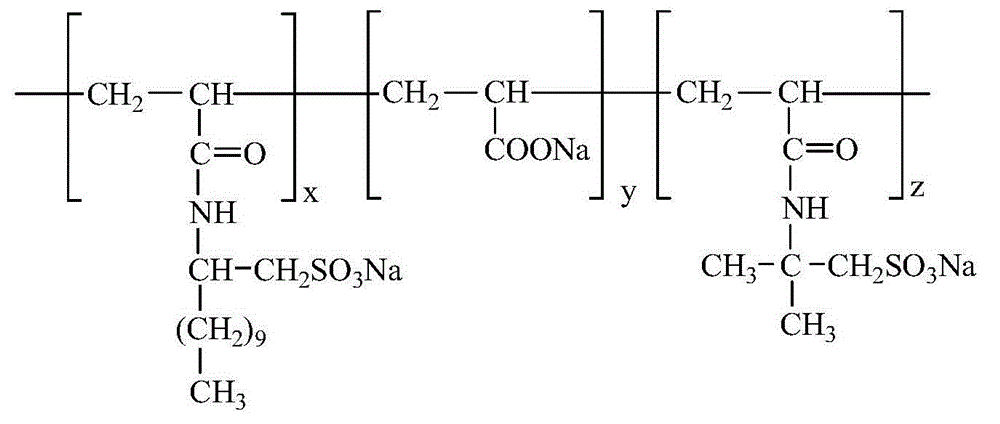

Embodiment 2

[0025] Dissolve 10g of methacrylic acid and 50g of sodium allyl sulfonate in 120g of clear water to obtain a mixed reaction monomer solution. For use, dissolve 0.55g of ammonium persulfate in 60g of clear water for use, and add 50g of 2-acrylamidodecane Sulfonic acid and 0.11g isopropanol were dissolved in 150g water and the temperature was raised to 40°C, then the mixed reaction monomer solution and ammonium persulfate solution were added to the reaction system, and then the system was heated to 100°C for 2h to obtain the solid phase content 25% surfactant product. After the reaction, the system is neutralized with sodium hydroxide to pH 8. After drying and pulverization, a surfactant for microbubble drilling fluid with an average molecular weight of 10,000 is obtained. Its structural formula is:

[0026]

[0027] The amount ratio of x:y:z substances is 3.4:2.3:6.9.

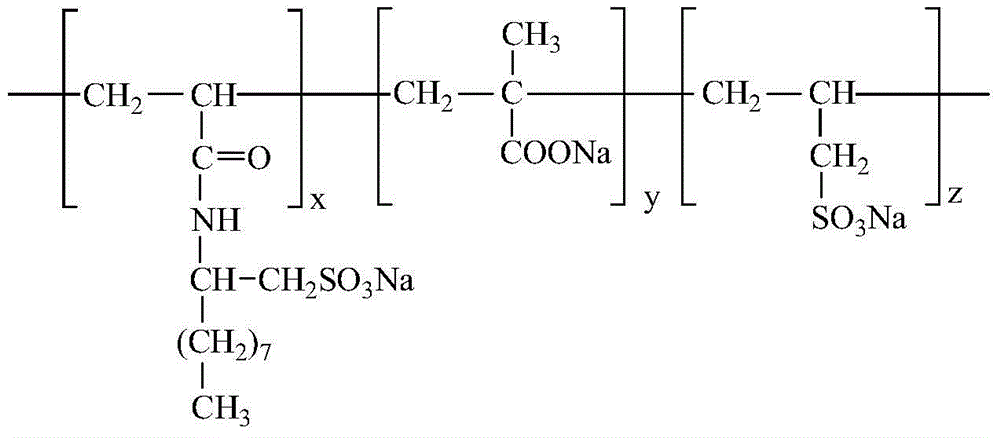

Embodiment 3

[0029] Dissolve 50g of itaconic acid and 30g of 2-acryloxybutyl sulfonic acid in 60g of clear water to obtain a mixed reaction monomer solution. For use, dissolve 1.3g of ammonium persulfate in 10g of clear water for use, and add 50g of 2-acrylamide Tetradecanesulfonic acid and 2.6g copper sulfate were dissolved in 60g water and the temperature was raised to 60°C, then the mixed reaction monomer solution and ammonium persulfate solution were added to the reaction system together, and then the system was heated to 95°C for 1.5h. A surfactant product with a solid content of 50% is obtained. After the reaction, the system is neutralized with sodium hydroxide to a pH value of 8.5. After drying and crushing, a surfactant for microbubble drilling fluid with an average molecular weight of 1000 is obtained. The structural formula is:

[0030]

[0031] The amount ratio of x:y:z substances is 2.9:7.7:2.9.

[0032] The steps in Examples 4 to 7 are the same as in Example 1. The reaction mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com