Surface treatment method for aluminum board

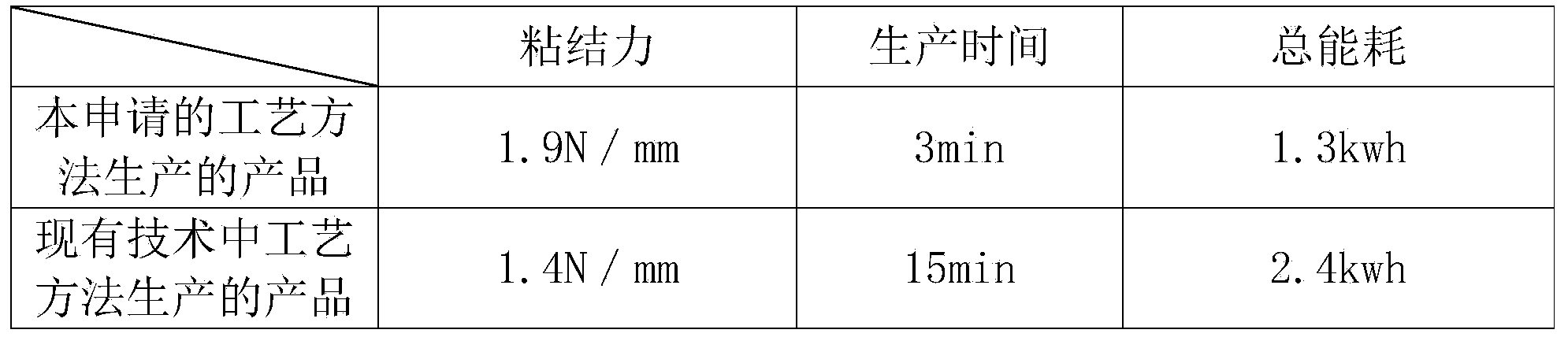

A surface treatment, aluminum plate technology, applied in the direction of metal material coating process, etc., can solve the problems of long oxidation time, low production efficiency, high power consumption, etc., to achieve good quality consistency, improved adhesion, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

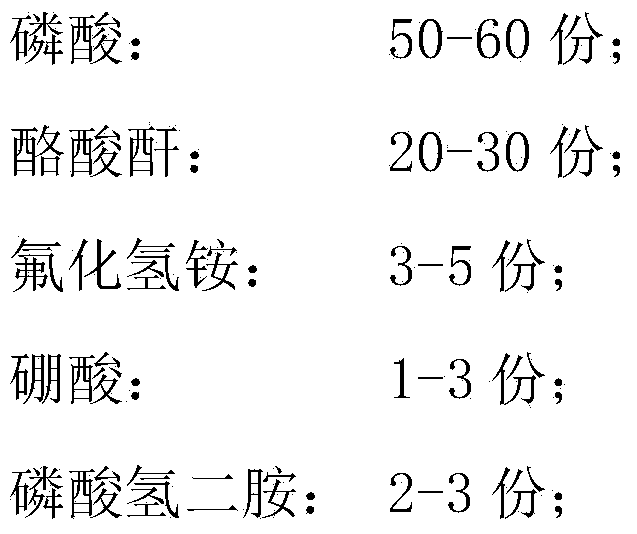

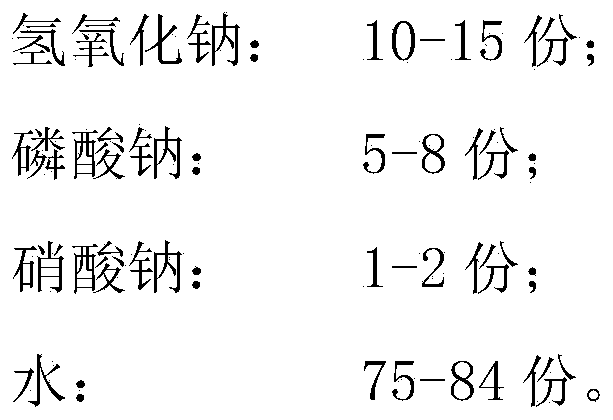

[0022] Taking the treatment of 1.5 tons of aluminum plate as an example, the surface treatment method of the aluminum plate includes the following steps: (1) Cleaning the surface of the aluminum plate: Use two non-woven brush rollers on the upper and lower sides to brush the two sides of the aluminum plate respectively. The purpose is to brush the surface of the aluminum plate and degrease it. That is to increase the specific surface area of the aluminum plate and remove the grease on the surface of the aluminum plate; (2) roughening the surface of the aluminum plate: the aluminum plate undergoes a chemical reaction in a strong alkali solution to further roughen the surface of the aluminum plate and ensure the adhesion between the aluminum plate and the insulating medium layer The temperature of the lye is 50-80°C, and the soaking time is 2-4min. The lye includes the following raw materials in parts by weight: sodium hydroxide: 20kg; sodium phosphate: 12kg; sodium nitrate: 2kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com