Heat field structure for fast increasing growth speed of czochralski silicon single crystal

A growth rate, Czochralski technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unfavorable crystal radiation heat absorption, reduce the heat dissipation effect of water cooling jacket, etc., to improve the pulling speed, reduce the surface temperature, the effect of accelerating the release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

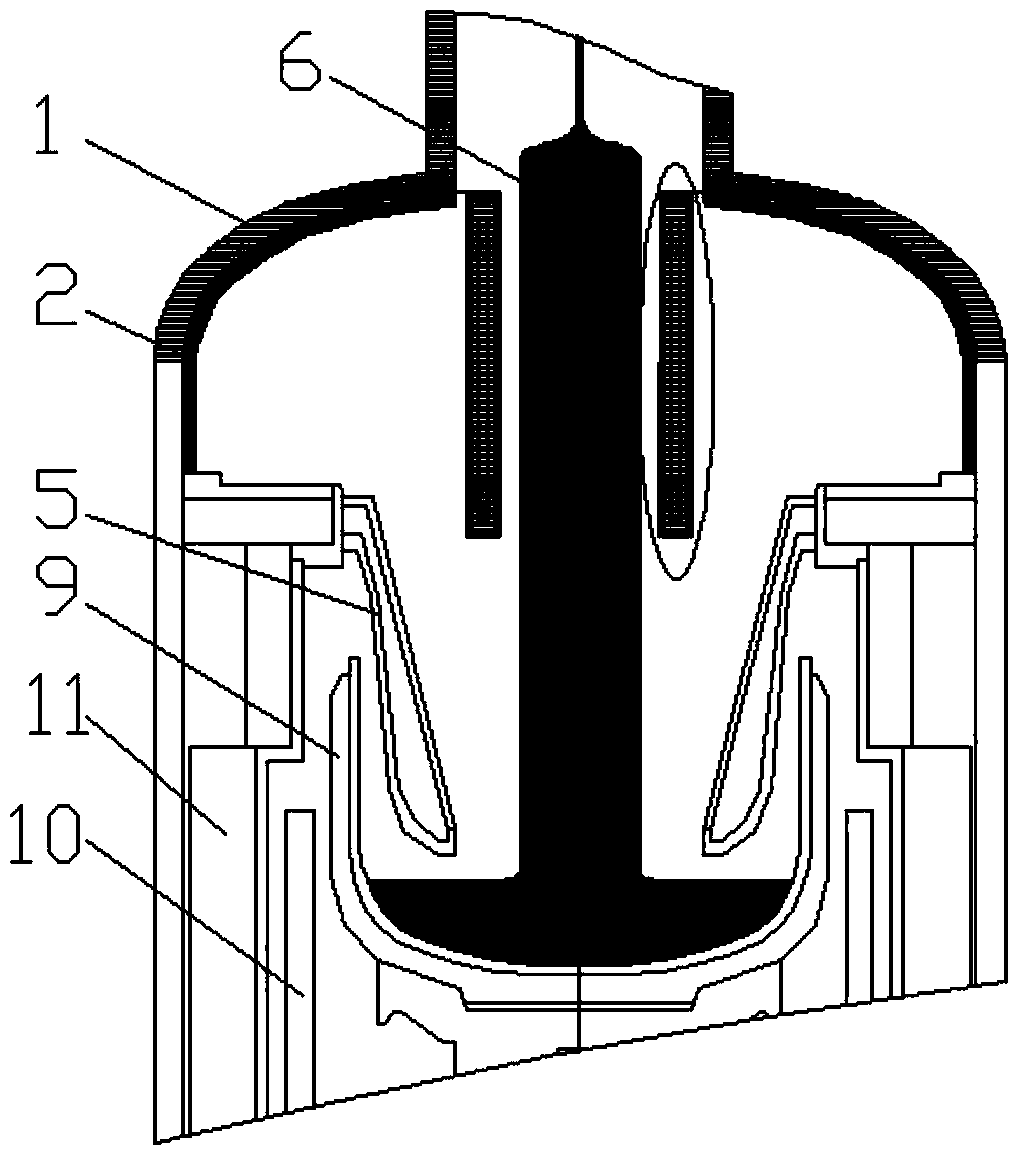

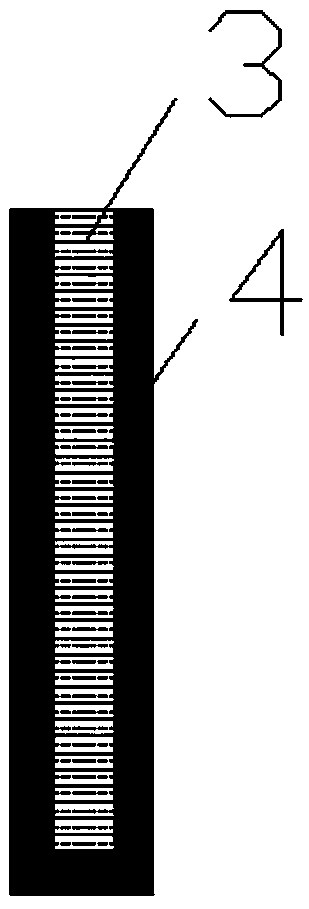

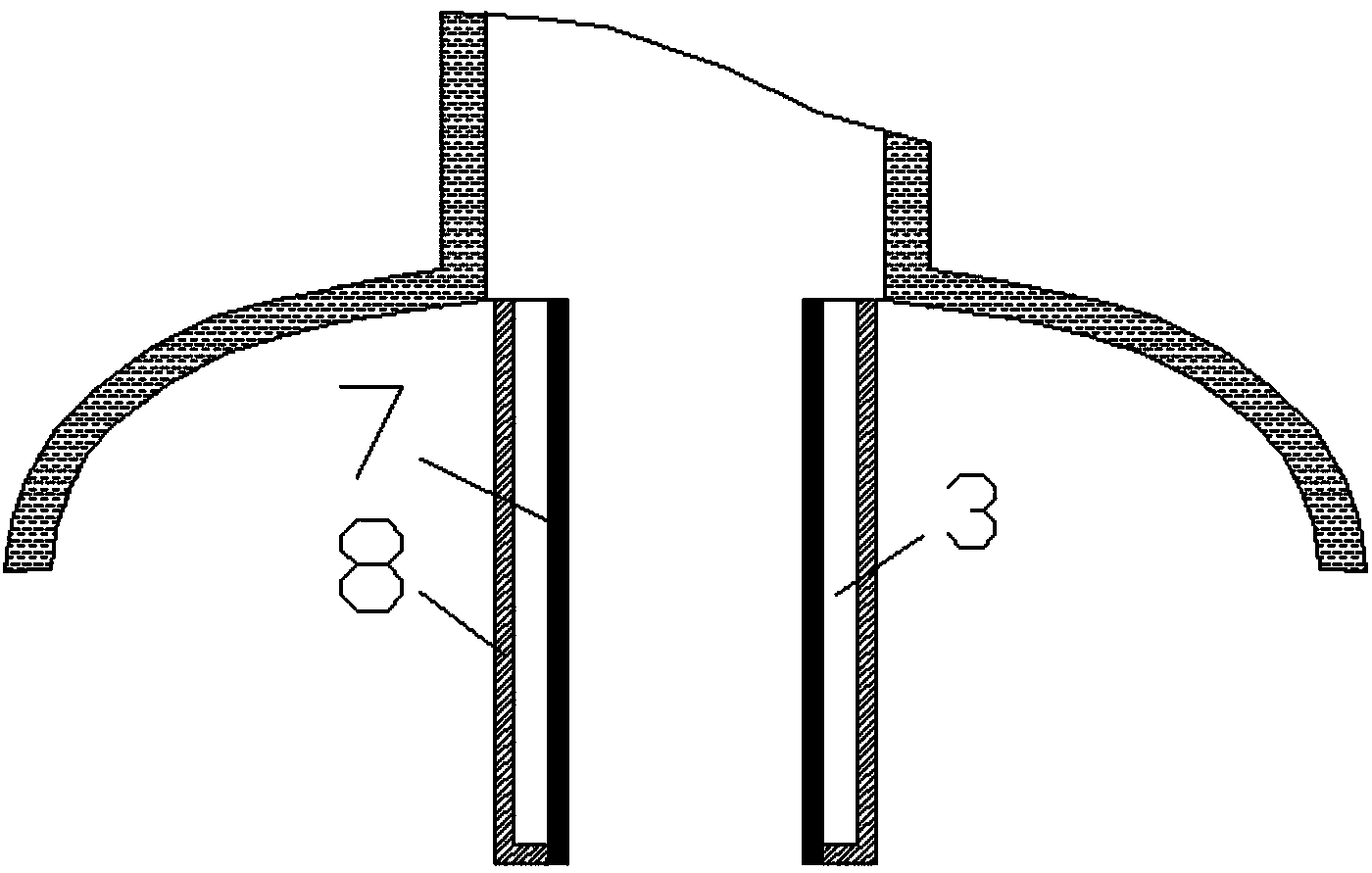

[0019] like figure 1 As shown, a thermal field structure for rapidly increasing the growth rate of Czochralski silicon single crystals includes a furnace body, a furnace cover 1, a crucible 9 located inside the furnace body, a heating device 10 located in the furnace body and outside the crucible 9, and a furnace body located outside the crucible 9. The heat preservation device 11 inside the body and outside the heating device 10, the draft cylinder 5 located inside the heat preservation device 11 and on the upper part of the crucible 9, and the single crystal rod lifting area 6 located inside the draft cylinder 5 and above the crucible 9, also includes water cooling Cover 3 and the outer absorption layer 4 of the water cooling jacket, the water cooling jacket 3 is a hollow cylindrical structure, the water cooling jacket 3 is arranged between the guide tube 5 and the single crystal rod lifting area 6, and the water cooling jacket can be directly fixed The inner wall of the fur...

no. 2 example

[0021] In the conventional Czochralski single crystal furnace as described in the first embodiment, the outer absorption layer 4 of the water-cooling jacket is added separately. The outer absorption layer 4 of the water-cooling jacket is directly coated on the surface of the water-cooling jacket 3 with a high absorption coefficient coating, and its effect is similar to that of Similar to the first embodiment, the crystal temperature gradient is increased to accelerate the release of crystallization latent heat, thereby rapidly increasing the crystal growth rate.

no. 3 example

[0023] In the conventional Czochralski single crystal furnace as described in the first embodiment, the outer absorption layer 4 of the water cooling jacket and the inner absorption layer 2 of the furnace cover are added simultaneously (structural materials or coating materials with high absorption coefficient can be selected), other technologies The features are the same as the first embodiment. Calculated by computer simulation, the average temperature of the silicon crystal surface can be reduced by about 21 degrees, and the maximum temperature difference can be reduced by about 33 degrees, which increases the crystal temperature gradient and accelerates the release of crystallization latent heat; Crystal heat dissipation, the effect of increasing the crystal temperature.

[0024] To sum up, by accelerating the release of crystallization latent heat, the effect of rapidly increasing the crystal growth rate can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com