Drainage and seepage type felting composite structure

A combined structure and pavement technology, applied to water supply devices, pavement details, waterway systems, etc., can solve problems such as difficult surface heat exchange, difficulty in large-scale promotion, and impossibility of water collection and utilization, so as to reduce urban heat island effect and construction and easy maintenance, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

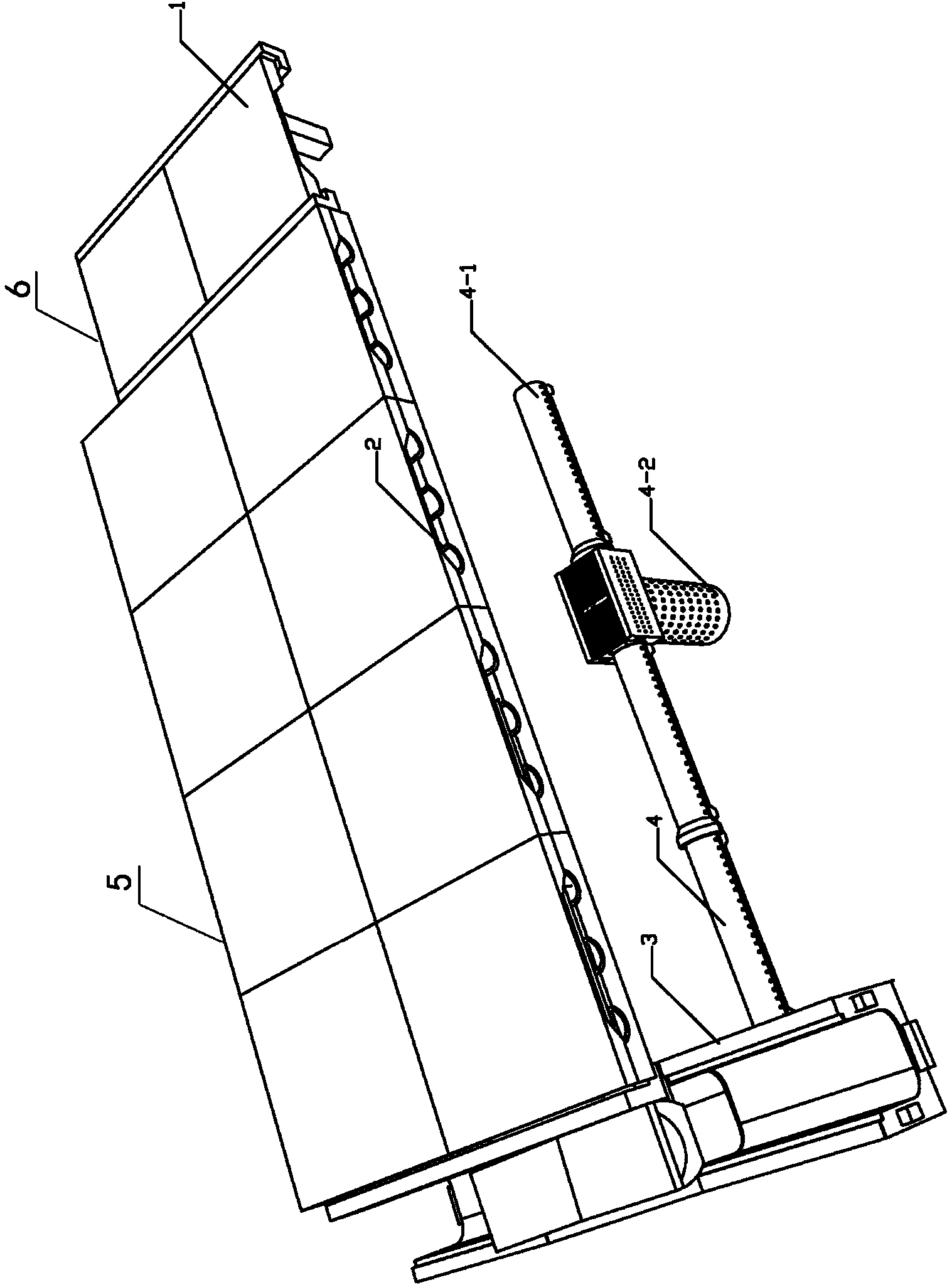

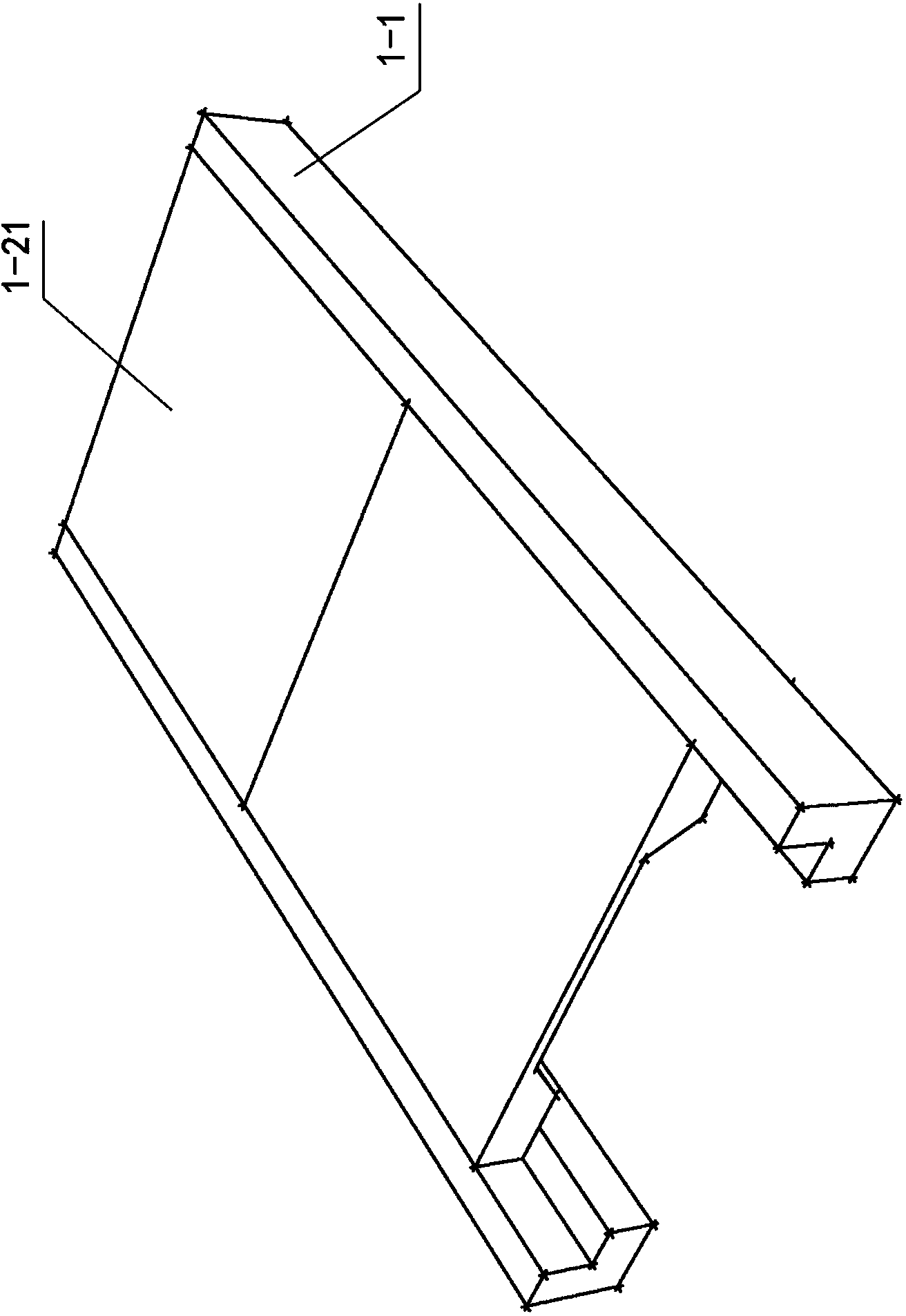

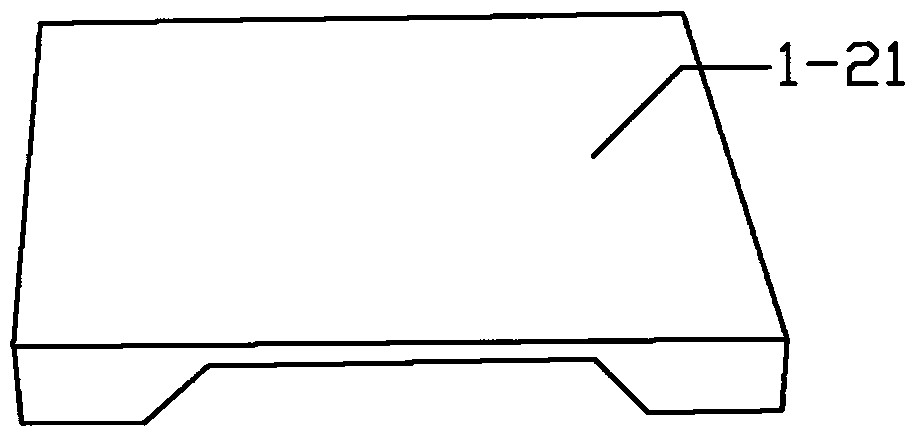

[0079] see figure 1 As shown, the seepage drainage beam-slab pavement composite structure of the preferred first embodiment of the present invention is mainly composed of a beam-slab pavement structure 1, a permeable PC base layer 2, a U-shaped ecological drainage ditch 3 and a seepage drainage pipe 4. Wherein, the beam-slab pavement structure 1 is installed on the permeable PC base layer 2, so that the permeable PC base layer 2 and the beam-slab type pavement structure 1 are combined to form a motorway or a square 5, which has the function of carrying loads. The sidewalks or non-motorized lanes 6 located on one side or both sides of the motorway or the square 5 are assembled from the plurality of beam-slab pavement structures 1 . Sidewalk or non-motorized vehicle lane 6 are provided with the side of motorized lane or square 5 in the present embodiment, see figure 1 . The U-shaped ecological drainage ditch 3 is installed on the sidewalk or the bicycle lane 6 or the side of t...

Embodiment 2

[0091] see Figure 10 As shown, in the preferred second embodiment of the present invention, the seepage drainage beam-slab pavement composite structure, the bottom of the PC pipe 4-12 of the horizontal PC pipe 4-1 is provided with a base 4-13. In the present embodiment, the sidewalk or the non-motorized lane 6 are arranged on both sides of the motorized lane or the square 5, and the U-shaped ecological drainage ditch 3 is arranged on both sides of the sidewalk or the non-motorized lane 6. Other structures are with embodiment 1.

Embodiment 3

[0093] see Figure 5 , Figure 3A , Figure 3B As shown, in the preferred third embodiment of the present invention, the seepage drainage beam-slab pavement composite structure, the lower bottom of the beam 1-1 is provided with a plurality of columns 1-3, the beam 1-1 is L-shaped, the The right-angled trapezoidal pier 1-23 of the inverted trapezoidal wedge panel 1-2 is arranged at the bottom of the L-shaped beam 1-1. In the present embodiment, the sidewalk or the non-motorized lane 6 is arranged on one side of the motorized lane or the square 5, and the U-shaped ecological drainage ditch 3 is arranged on the side of the sidewalk or the non-motorized lane 6. Other structures are with embodiment 1.

[0094] By using the above embodiments of the invention, the rainwater can be infiltrated into the surface soil of residential areas, office areas, squares, etc. to the maximum extent. When the rainfall is heavy, the rainwater that has no time to infiltrate can be discharged into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com