Balance valve for preventing traction motor from leaking oil, bearing cap provided with balance valve and traction motor

A technology for traction motors and balance valves, applied in the direction of balance valves, bearing components, shafts and bearings, etc., can solve the problems of polluting the environment, polluting the traction motor casing and the outside of the gearbox, etc., and achieve low cost, simple structure and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0028] A locomotive traction gear box is provided with a ventilation hole, and the air pressure inside the gear box is normally one atmospheric pressure. If the bearing chamber of the traction motor is under negative pressure, the oil in the gearbox will easily escape from the labyrinth oil seal of the sealing ring to the bearing chamber under the action of the negative pressure. The invention provides a balance valve for preventing oil leakage of a traction motor. The balance valve is installed at the leakage port of the large-end bearing cover of the traction motor of a locomotive to prevent the formation of negative pressure.

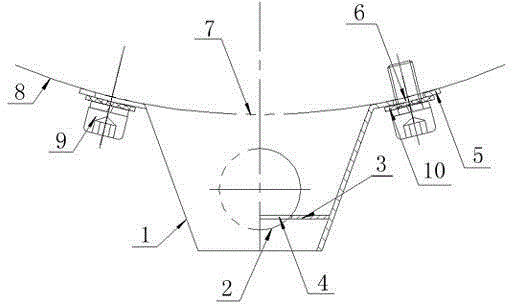

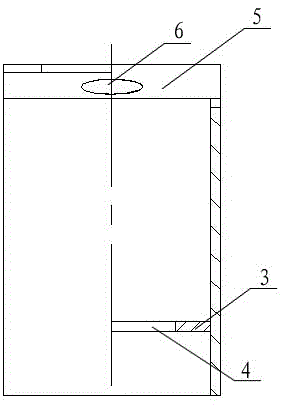

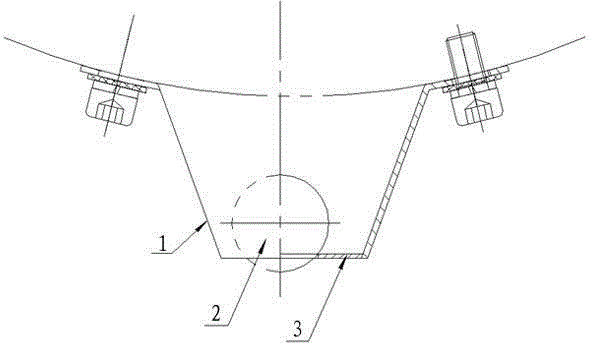

[0029] Such as figure 1 As shown, a balance valve for preventing oil leakage of a traction motor includes a valve body 1 and a valve core 2, a wall 3 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com