Biomass low-temperature pre-burning low-volatile inferior coal low-NOx combustion device

A low-volatile, combustion device technology, applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problems of backward emission control, high emission, difficult ignition, etc., to save energy, improve economic benefits, improve The effect of combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

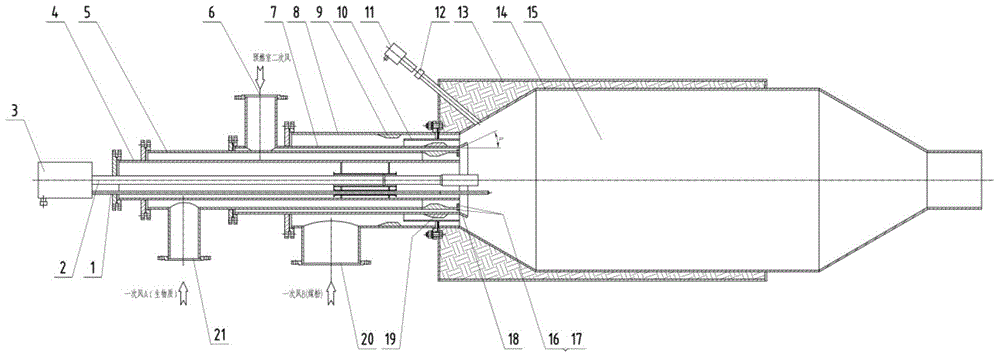

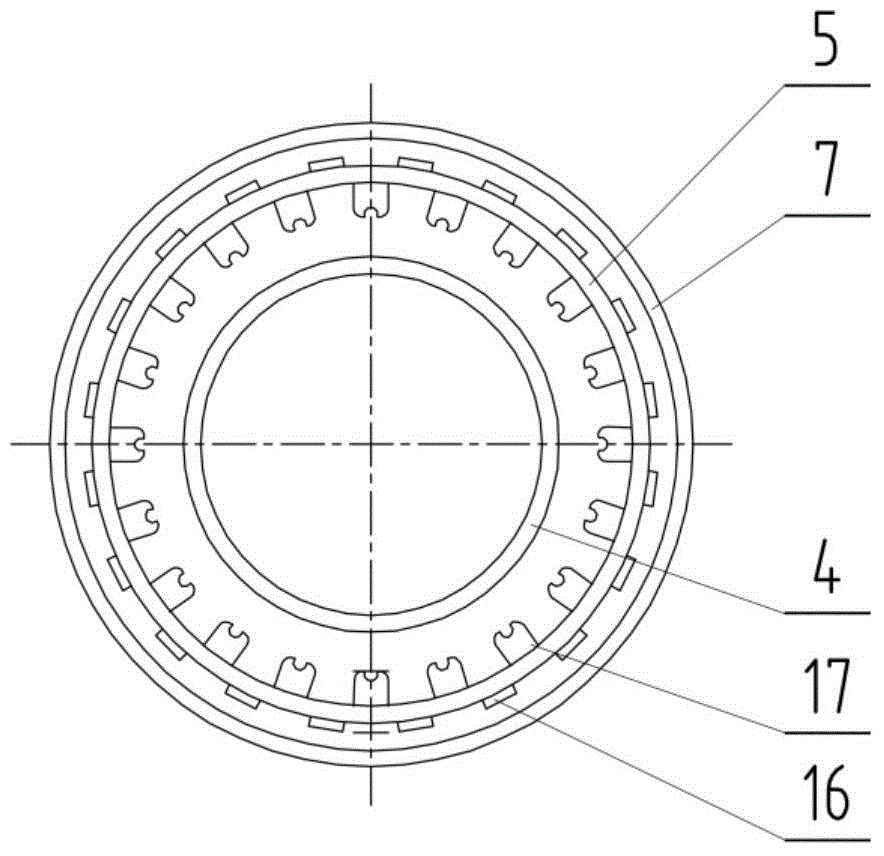

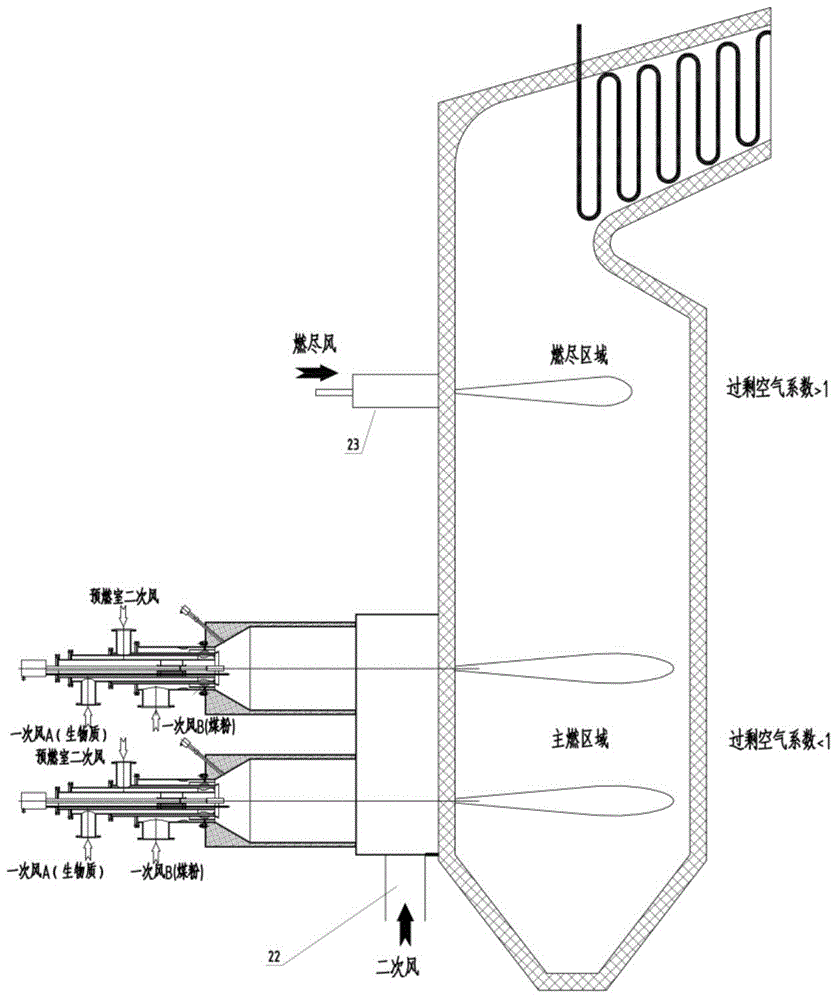

[0030] see Figure 1 to Figure 3 , the present invention comprises at least one boiler secondary air inlet 22, the boiler secondary air inlet 22 is connected with the pre-combustion chamber 15 surrounded by the pre-combustion inner casing 14, and the top of the boiler secondary air inlet 22 is provided with an exhaust air The inlet 23, the secondary air inlet 22 and the burn-off air inlet 23 correspond to a main combustion area and a burn-out area; the burn-out area is located above the combustion-supporting area. The pre-chamber inner shell 14 is covered with the pre-chamber outer shell 13 with an open bottom; Aluminum silicate refractory fibers are filled between the pre-combustion inner shell 14 and the pre-combustion outer shell 13 . The pre-combustion chamber 15 is also equipped with an infrared flame detection device 11 and a fire sighting device 12 . The entran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com