Automatic mercury thermometer calibration method based on machine vision

A mercury thermometer and machine vision technology, used in thermometers, thermometer testing/calibration, instruments, etc., can solve problems such as large estimation error, human eye fatigue failure, slow speed, etc., to improve production efficiency and quality, and improve product competition. power and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

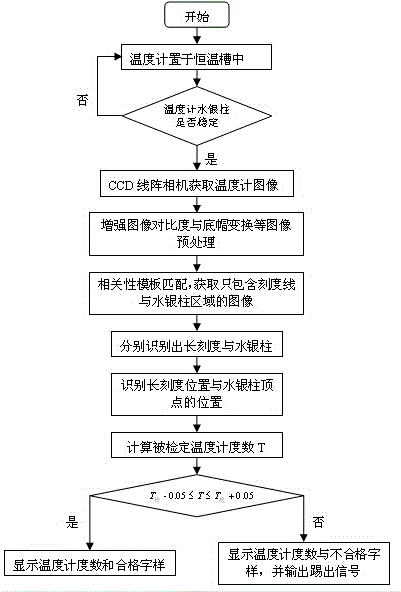

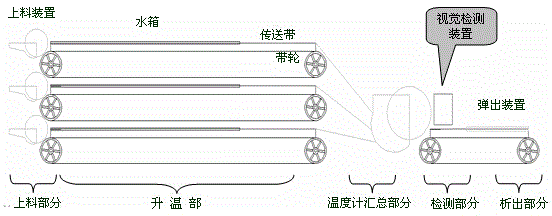

[0024] Embodiment 1 A kind of automatic verification method of mercury thermometer based on machine vision, flow process is as follows figure 1 as shown, figure 2 It is a schematic diagram of the automatic verification system for mercury thermometers based on machine vision of the present invention.

[0025] The specific steps are:

[0026] 1) Put the thermometer to be verified in the constant temperature tank until the mercury column is stable, and the temperature of the constant temperature tank is the verification temperature .

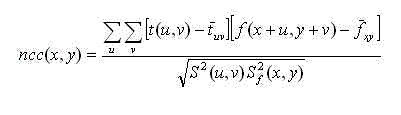

[0027] 2) Use the CMOS line array camera to collect the image of the mercury thermometer processed in step 1, and transfer the image to the computer and use the HALCON machine vision software to perform preprocessing such as contrast enhancement and bottom hat transformation on the obtained image. The bottom hat transformation (bot-hat) is an algorithm that subtracts the original image from the closed operation image. Assume is the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com