Method for recovering oxidation function of oxidizing furnace packing in methane enrichment analyzer

An oxidation furnace and analyzer technology, which is applied to the field of restoring the oxidation function of the packing used in the oxidation furnace of the methane enrichment analyzer, can solve the problems of weakening oxidation ability, affecting the sample conversion rate and analysis accuracy, etc., and achieves the restoration of oxidation ability and good use. And the effect of promoting value and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

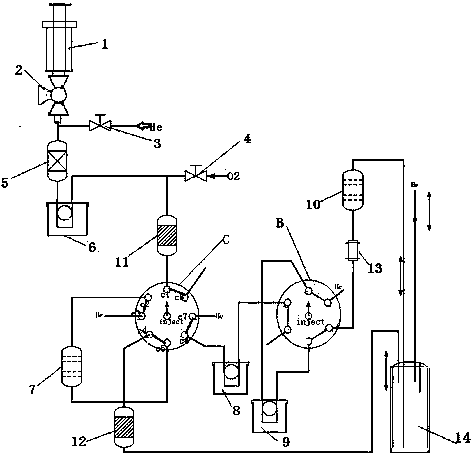

[0011] Below, in conjunction with accompanying drawing, this method is further described:

[0012] Such as figure 1 As shown, the method for recovering the oxidation function of the oxidation furnace filler in the methane enrichment analyzer mainly includes: sample tube 1, sample tube valve 2, sample guide valve 3, oxygen injection valve 4, chemical trap 5, pre-freezing cold trap 6. Water trap 7, enrichment cold trap 8, transfer cold trap 9, adsorption water trap 10, oxidation furnace 11, Cr reaction furnace 12, chromatographic column 13, gas stable isotope ratio mass spectrometer (MS) 14, six channels Eight contacts of valve B and eight-way valve C: c1, c2, c3, c4, c5, c6, c7, c8.

[0013] While the gas sample contained in the sample tube 1 enters the chemical trap 5 through the sample tube valve 2, the He carrier gas with a flow rate of 12ml / min is introduced from the sample guide valve 3, and after passing through the chemical trap 5 and the pre-freezing cold trap 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com