Integrated SF6 gas density controller

A gas density, SF6 technology, applied in various fluid ratio control and other directions, can solve problems such as troublesome maintenance work, inability to intuitively understand equipment status, and no signal remote transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

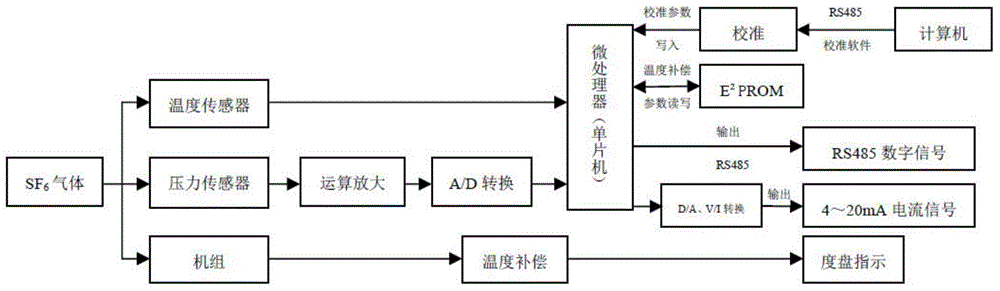

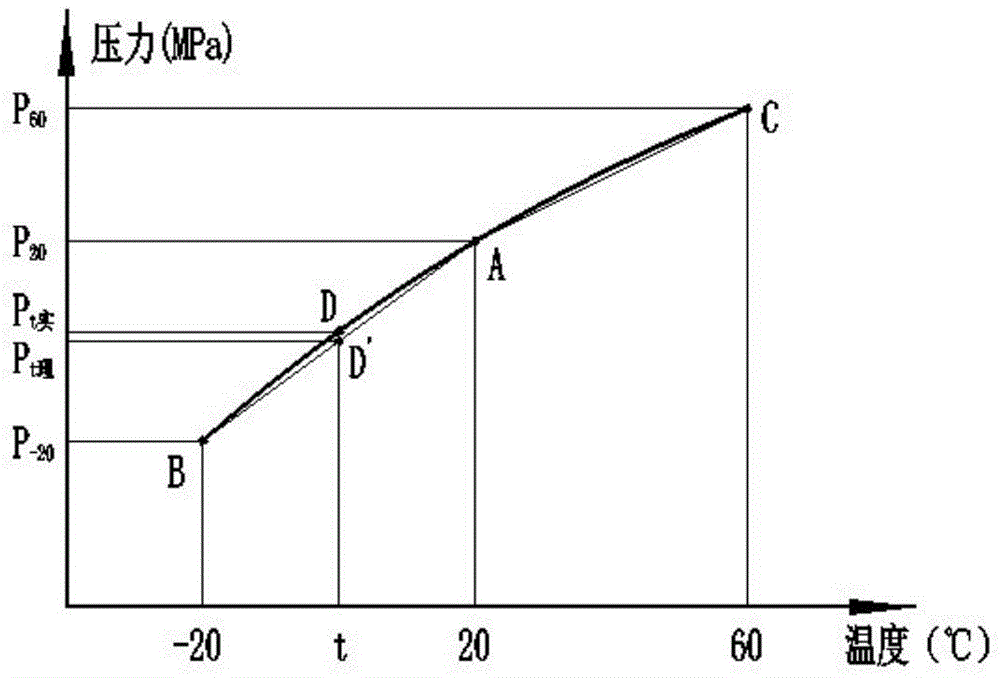

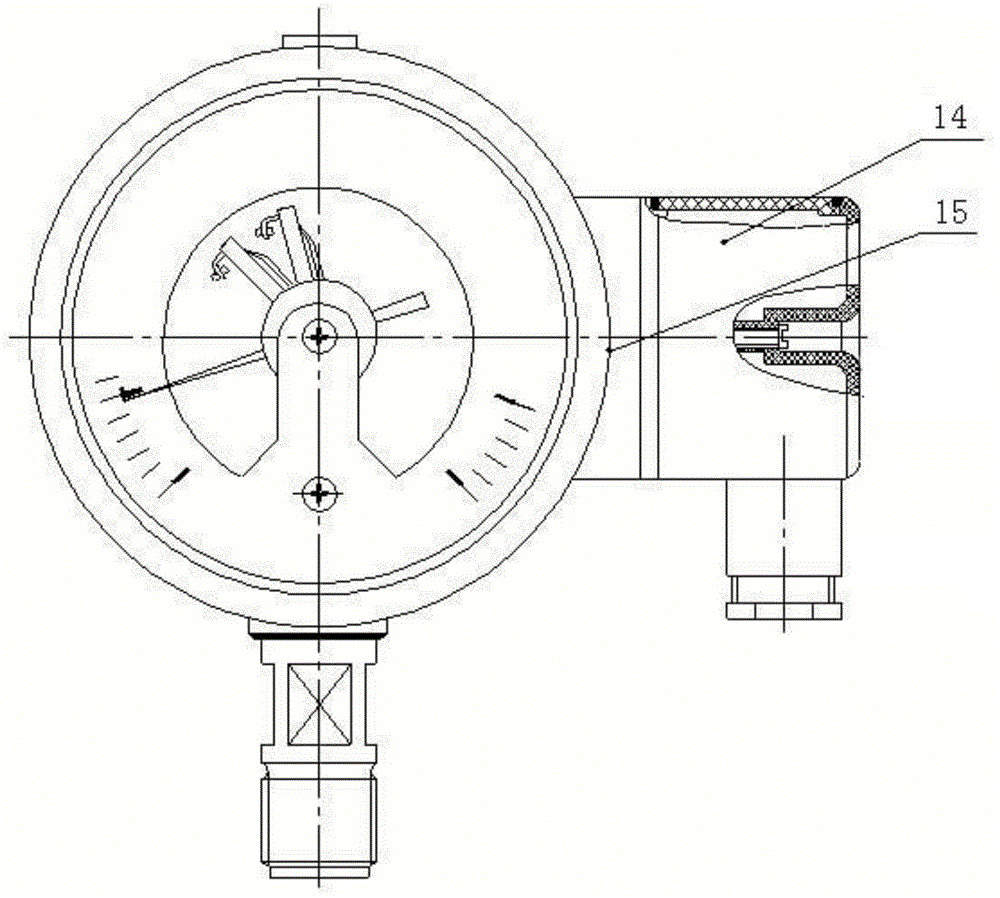

[0016] like Figure 1-6 Shown, one-piece SF 6 The gas density controller is mainly composed of a unit, a core, an instrument dial and a shell, a spring tube, a compensation element, a pressure element, a pressure sensor, a temperature sensor, an amplification and compensation circuit, a V / I conversion circuit, and a microprocessor (single-chip microcomputer) ,E 2 PROM (including temperature compensation program) and other components. The unit, movement, instrument dial, casing, spring tube, compensation element, etc. constitute the mechanical part of the controller, which are used for indication and control signal output; pressure sensors and temperature sensors are used to detect SF 6 The pressure and temperature of the gas in the high-voltage electrical equipment are converted into corresponding electrical signals and sent to the single-chip microcomputer. The single-chip microcomputer uses the E 2 The pressure-temperature comprehensive compensation software in the PROM o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com