Design method of large caliber optics telescope four way structure and obtained four way structure

A design method and telescope technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of long design cycle and low structural lightweight rate, so as to facilitate system operation and control, shorten design cycle, and reduce quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

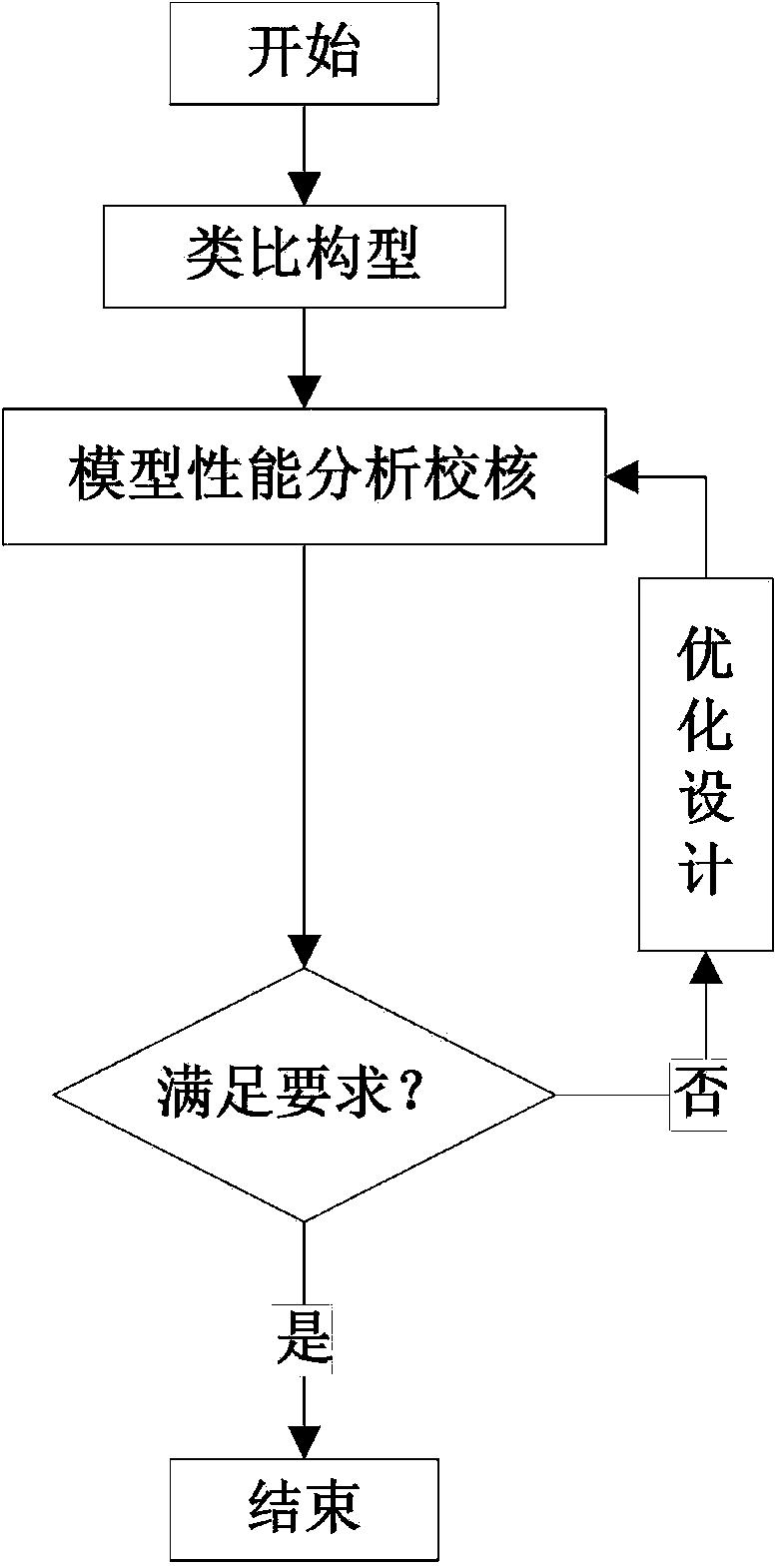

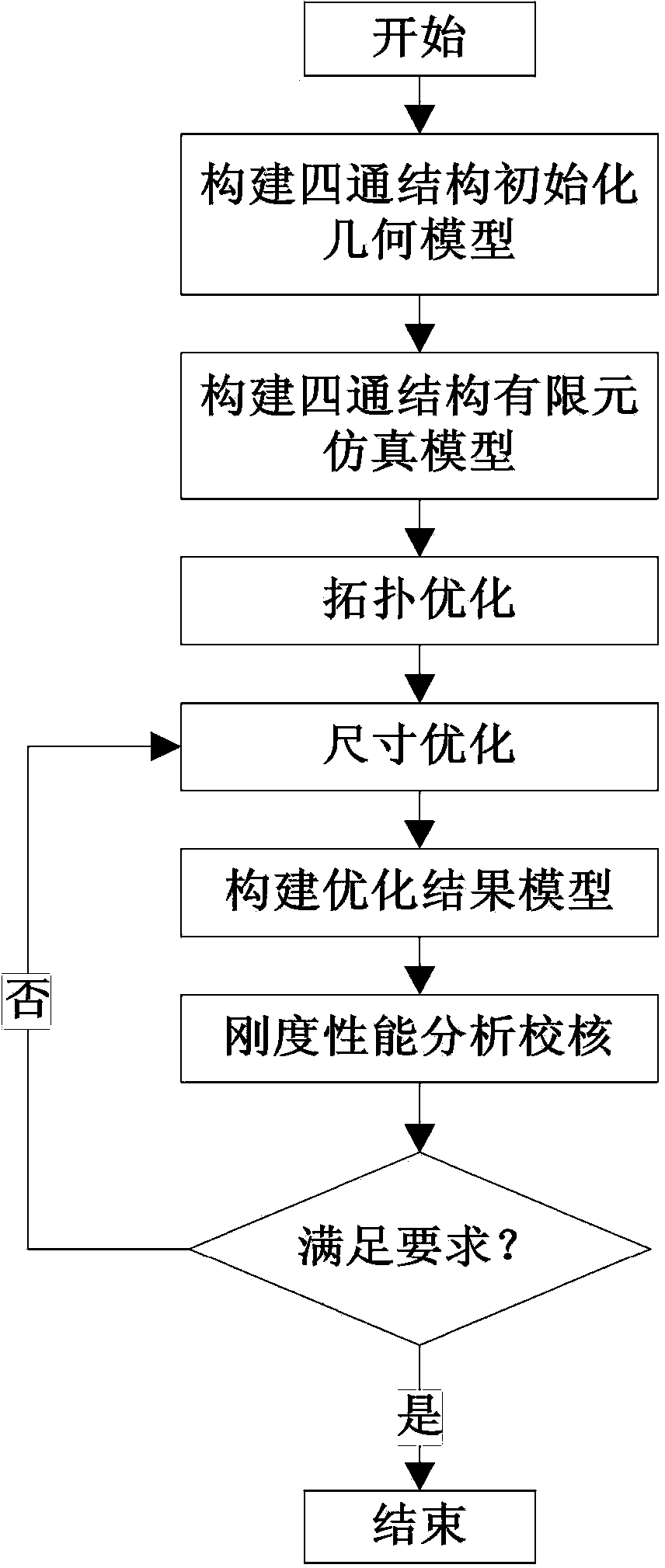

[0041] like figure 2 Shown, the design method of large aperture optical telescope four-way structure of the present invention comprises the following steps:

[0042] Step 1. Construct the initial geometric model of the four-way structure

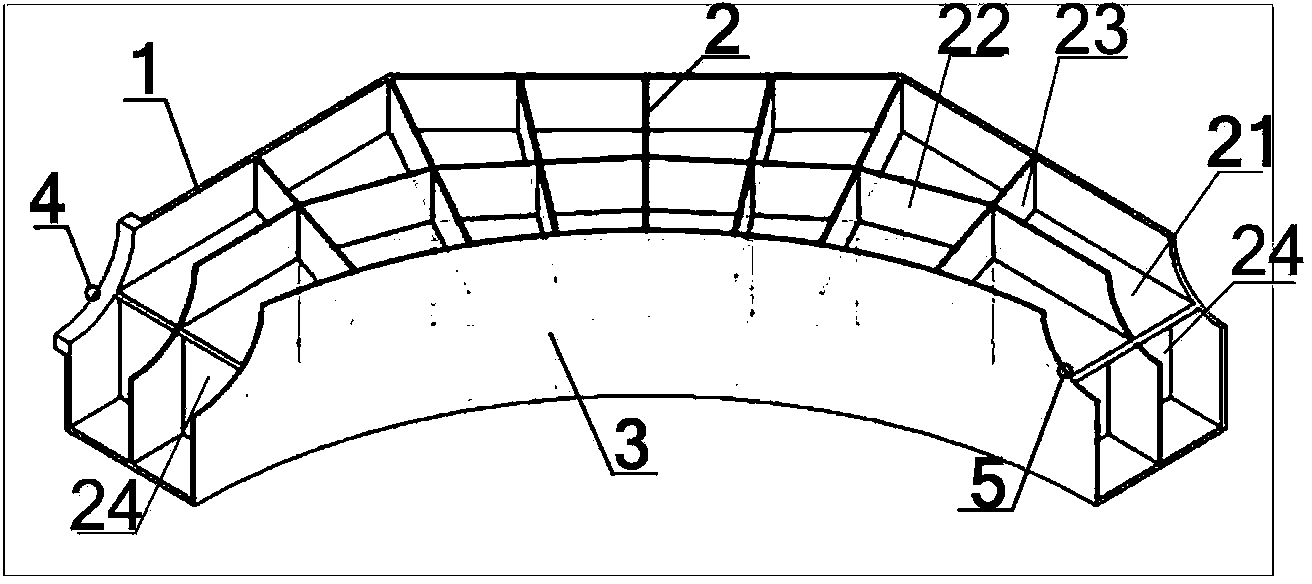

[0043] According to the requirements of design and assembly, the shape parameters of the four-way structure are determined, including local shape parameters such as the installation hole 4 and the light hole 5, and the initial geometric model of the four-way structure before optimization is constructed. The initial geometric model of the four-way structure is obtained as follows: Figure 5 shown.

[0044] Step 2. Construct the finite element simulation model of the four-way structure

[0045] The finite element method (FEA) is used to discretize the initial geometry model of the four-way structure obtained in step 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com