A TSV process

A technology of TSV and process, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as destroying semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

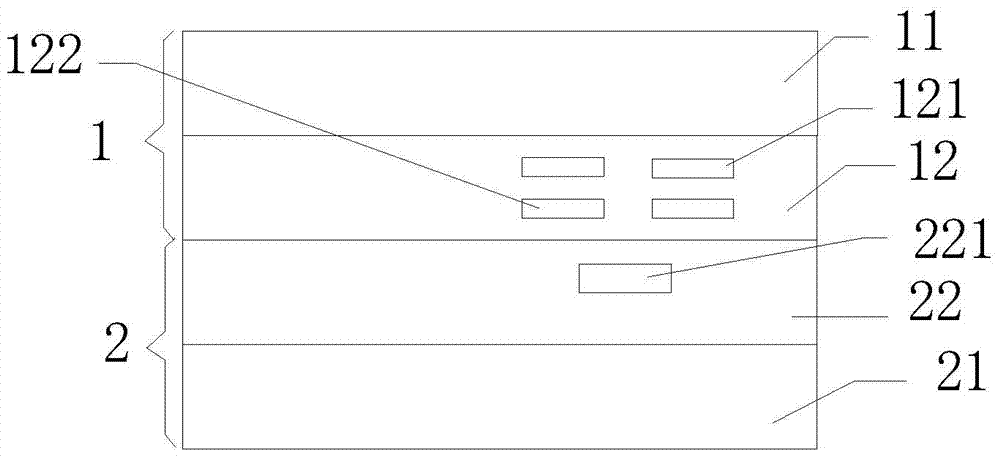

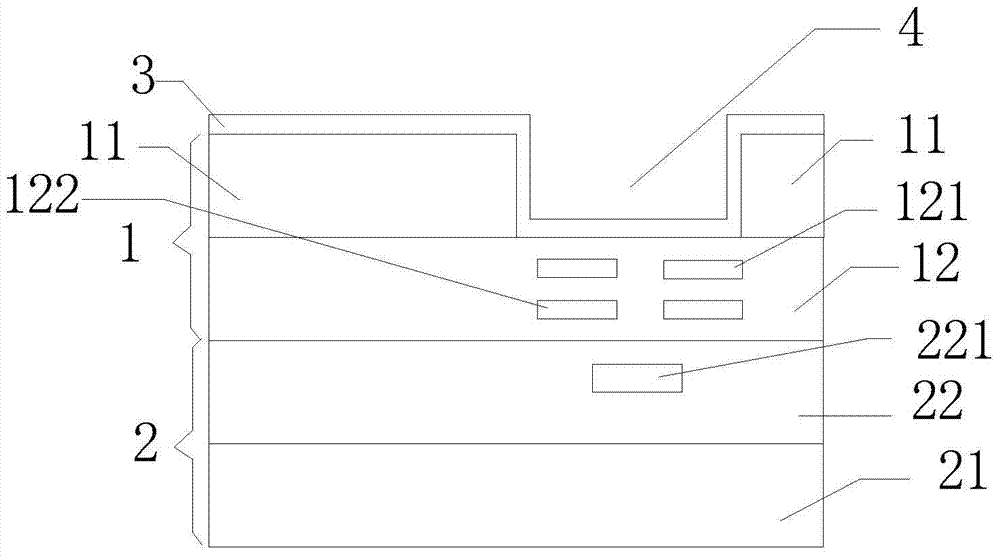

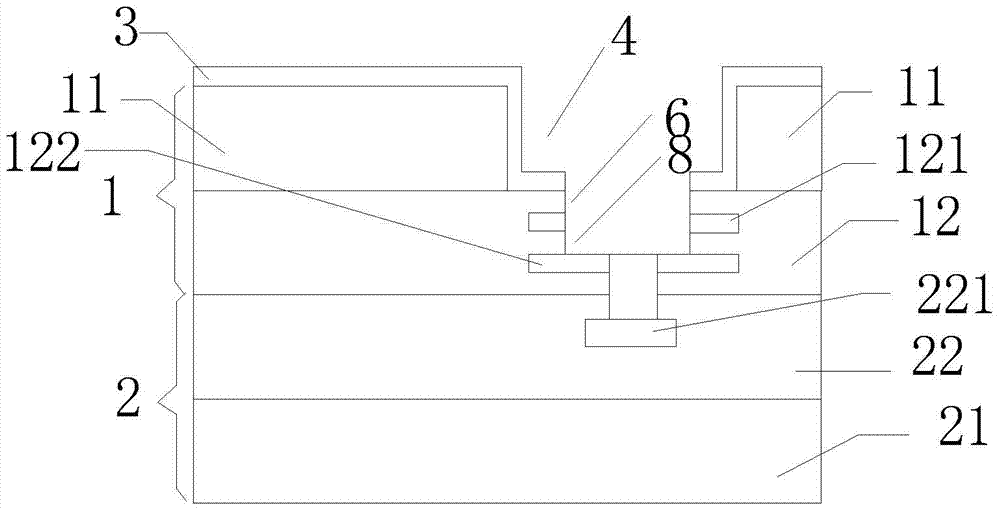

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] In view of the above existing problems, the present invention discloses a through-silicon via process, which effectively solves the damage of semiconductor devices caused by charge accumulation in the cross-wafer through-silicon via interconnection process. Part of the second metal layer contained in the first BEOL dielectric layer and part of the third metal layer contained in the second BEOL dielectric layer are connected to the semiconductor device, so that the chip is reduced in size without affecting performance, and the traditional three-dimensional wafer is completed. Integration; at the same time, part of the first metal layer contained in the first BEOL dielectric layer is not connected to any device to achieve the effect of grounding, which can overcome the long-term bombardment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com