Wire winding machine for stator core of motor

A motor stator and winding machine technology, which is applied in the field of motor stator core winding machines, can solve problems such as single structure of winding nozzles, low winding efficiency, and inability to realize automation, so as to solve the instability of power grid voltage and improve production Efficiency, beautiful shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

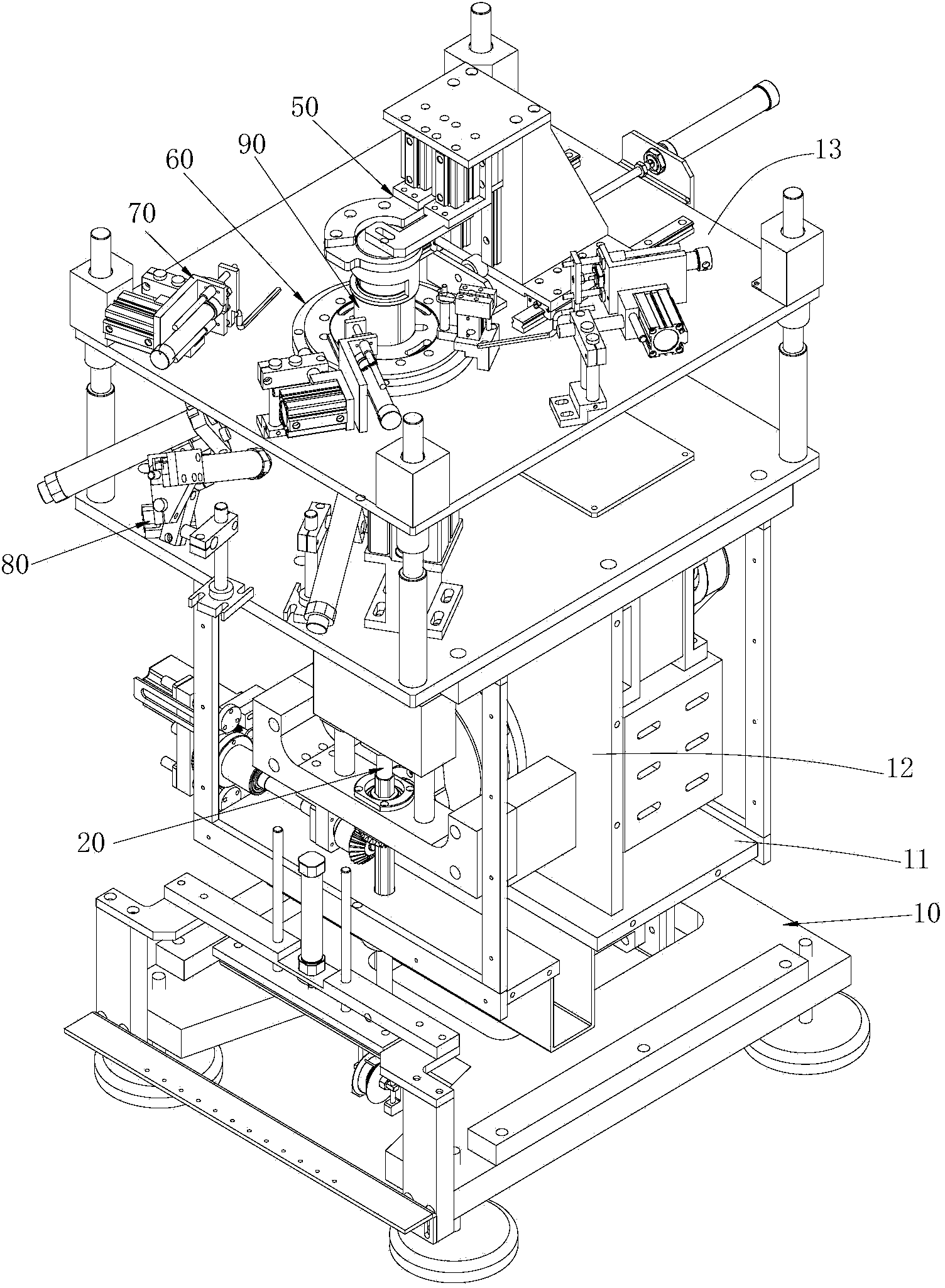

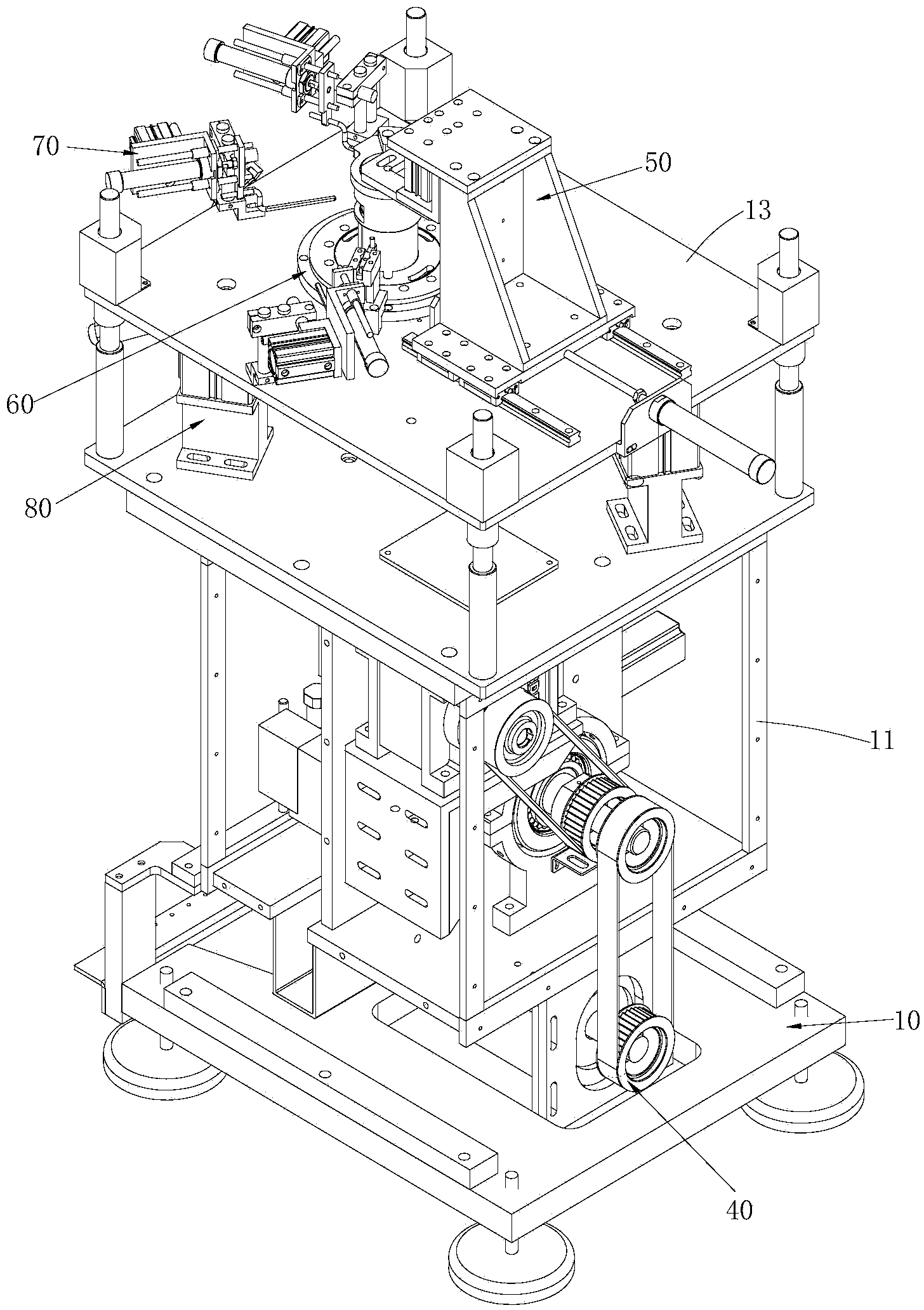

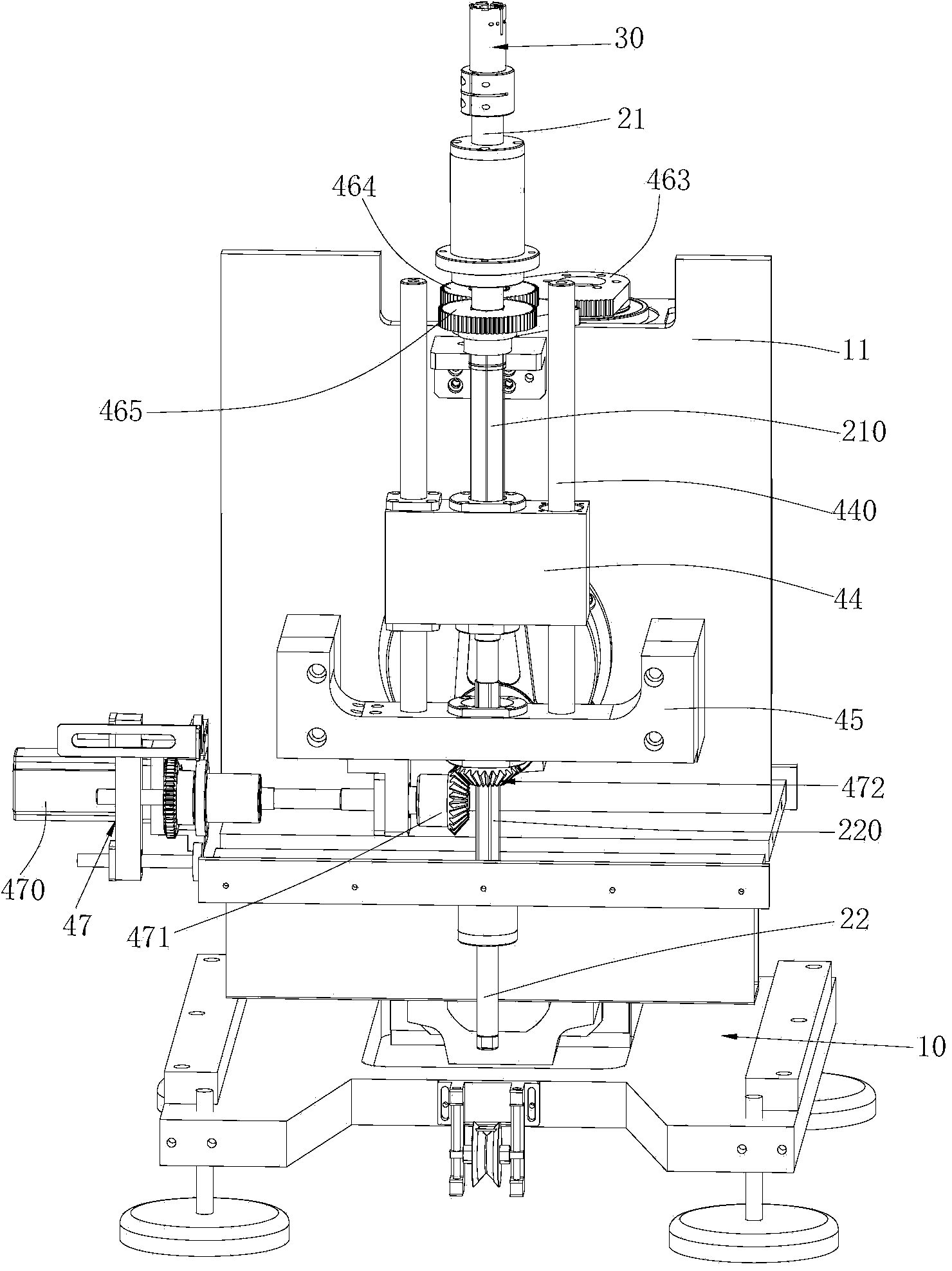

[0093] Such as figure 1 with figure 2 As shown, the motor stator core winding machine of the present invention consists of a frame 10, a wire arrangement 20, a wire winding mold 30, a driving mechanism 40, an axial compression device 50 of the stator core, an indexing mechanism 60, and a pick The thread mechanism 70 and the thread trimming mechanism 80 are composed. The following describes each part and the relationship between them in detail:

[0094] Such as figure 1 with figure 2 As shown, the rack 10 includes a frame frame 11, a mounting plate 12 arranged longitudinally along the frame frame 11, an upper panel 13 arranged horizontally along the frame frame 11 and above the mounting plate 12, the mounting plate 12 and the upper panel 13 are both It is arranged on the frame body 11, the mounting plate 12 is located in the middle of the frame body 11 and is fastened to the frame body 11 by bolts or welding as a whole, and the upper platform panel 13 is provided with a mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com