Rubber use high dispersing insoluble sulfur pre-dispersion mother colloidal particle and preparation method thereof

A technology for pre-dispersing master batches and dispersing active agents, applied in the field of rubber additives, can solve problems such as poor dispersion, user troubles, and vulcanized rubber performance degradation, achieve simple and easy processing methods, improve poor dispersion problems, and improve The effect of performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

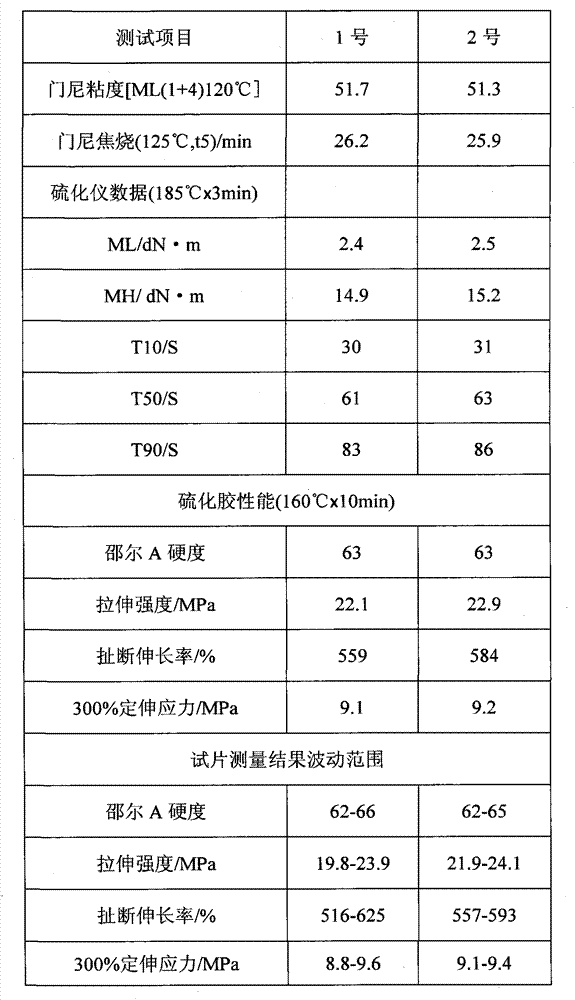

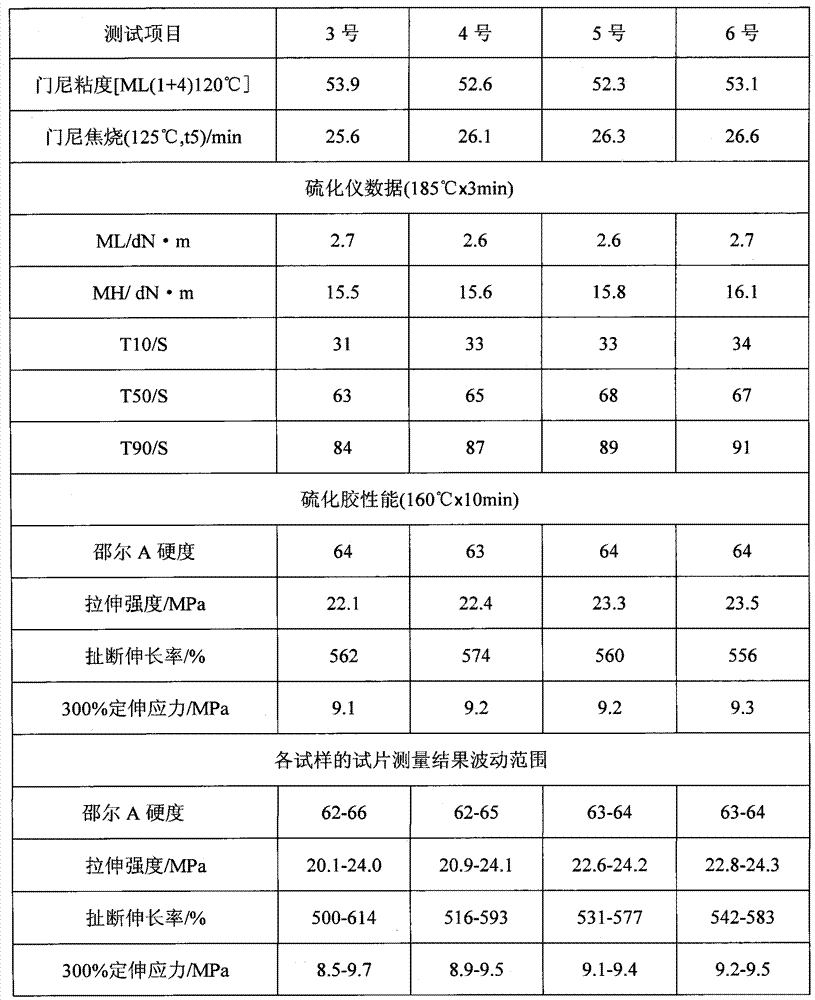

Embodiment 1

[0016] The formula is composed by weight: 100 phr oil-extended, 7 parts of EPDM with Mooney viscosity [ML(1+4)125°C] of 54, 3 parts of EVA with melting point of 58°C, 3 parts of stearic acid, 7 parts of naphthenic oil, oil Alcohol 2 parts, insoluble sulfur IS60-10 78 parts. Preheat the internal mixer to 60°C, put all EPDM, EVA and 1 part of stearic acid into the internal mixer and knead for 2 minutes, then add two thirds of insoluble sulfur, remaining stearic acid, oleyl alcohol, three parts Two-weight naphthenic oil was kneaded for 3 minutes; finally, the remaining insoluble sulfur and naphthenic oil were added and kneaded for 3 minutes, then the material was discharged, and then pelletized by an extruder to obtain insoluble sulfur masterbatch IS60-70.

Embodiment 2

[0018] The formula is composed by parts by weight: oil-extending 50phr, 6 parts of EPDM with Mooney viscosity [ML(1+4)125°C] of 46, 6 parts of BR9000, 2 parts of pentaerythritol stearate, 2 parts of naphthenic oil, 2 parts of oleyl alcohol Parts, insoluble sulfur IS-HS70-20 81.5 parts. Preheat the internal mixer to 50°C, put all EPDM, BR9000 and one third of pentaerythritol stearate into the internal mixer and knead for 2 minutes, then add two thirds of insoluble sulfur and the remaining pentaerythritol tetrastearate Ester, oleyl alcohol, and two-thirds of naphthenic oil were mixed for 3 minutes, and finally the remaining insoluble sulfur and naphthenic oil were added and mixed for 3 minutes, then the material was discharged, and the extruder was used to granulate to obtain insoluble sulfur masterbatches IS90-65.

Embodiment 3

[0020] The formula is composed by parts by weight: 9 parts of SBR1502, 1 part of stearic acid, 2 parts of oleyl alcohol, and 88 parts of insoluble sulfur IS-HS70-20. Preheat the internal mixer to 55°C, put SBR1502 and one third of stearic acid into the internal mixer and knead for 2 minutes, then add two thirds of insoluble sulfur, remaining stearic acid and oleyl alcohol for kneading 3 Minutes, finally add the remaining insoluble sulfur and knead for 3 minutes, discharge the material, and granulate on the extruder to obtain the insoluble sulfur masterbatch IS90-70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com