Process for processing high concentration refractory organic wastewater containing paratoluidine

A technology of organic wastewater and p-toluidine, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve ecological environmental pollution, restrict sustainable development and other problems, and achieve ecological protection Environment, protection of copper mine development, and the effect of simple and easy treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

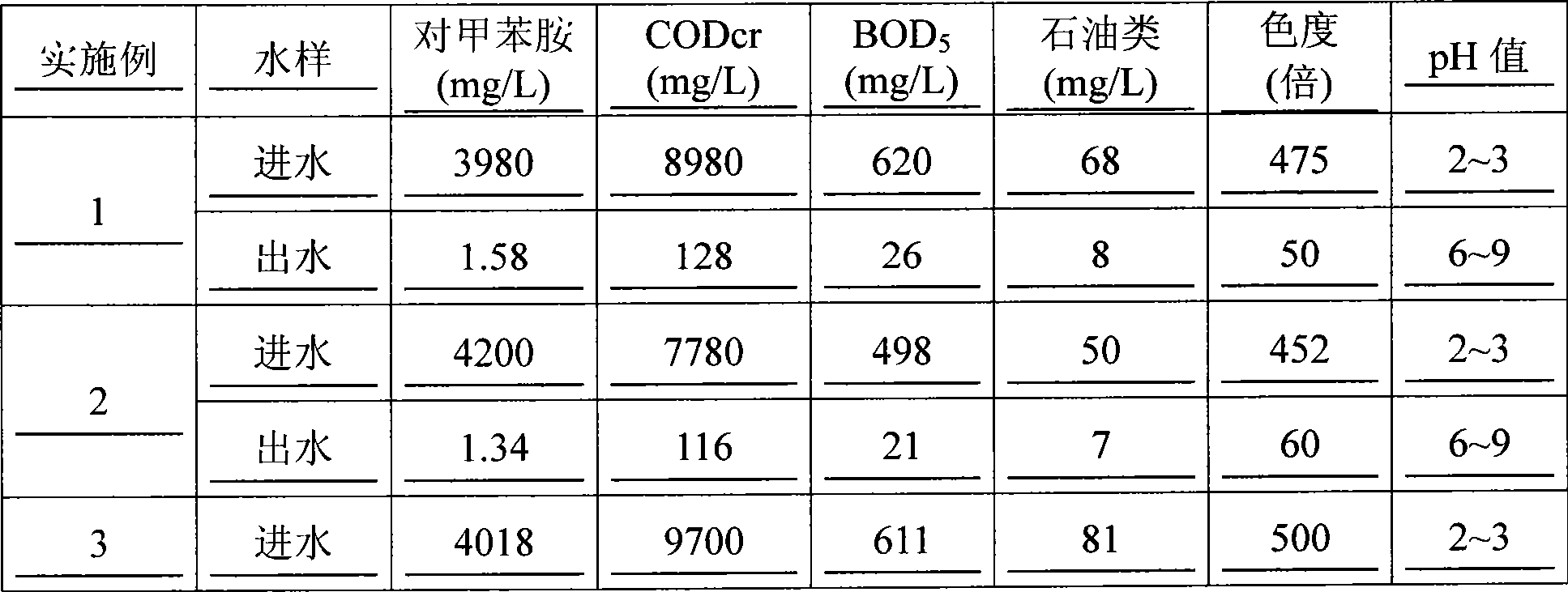

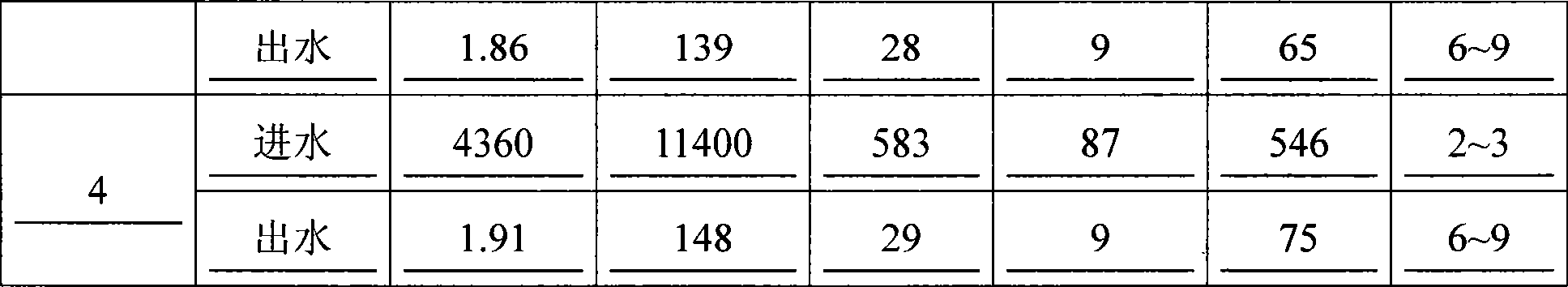

Examples

Embodiment Construction

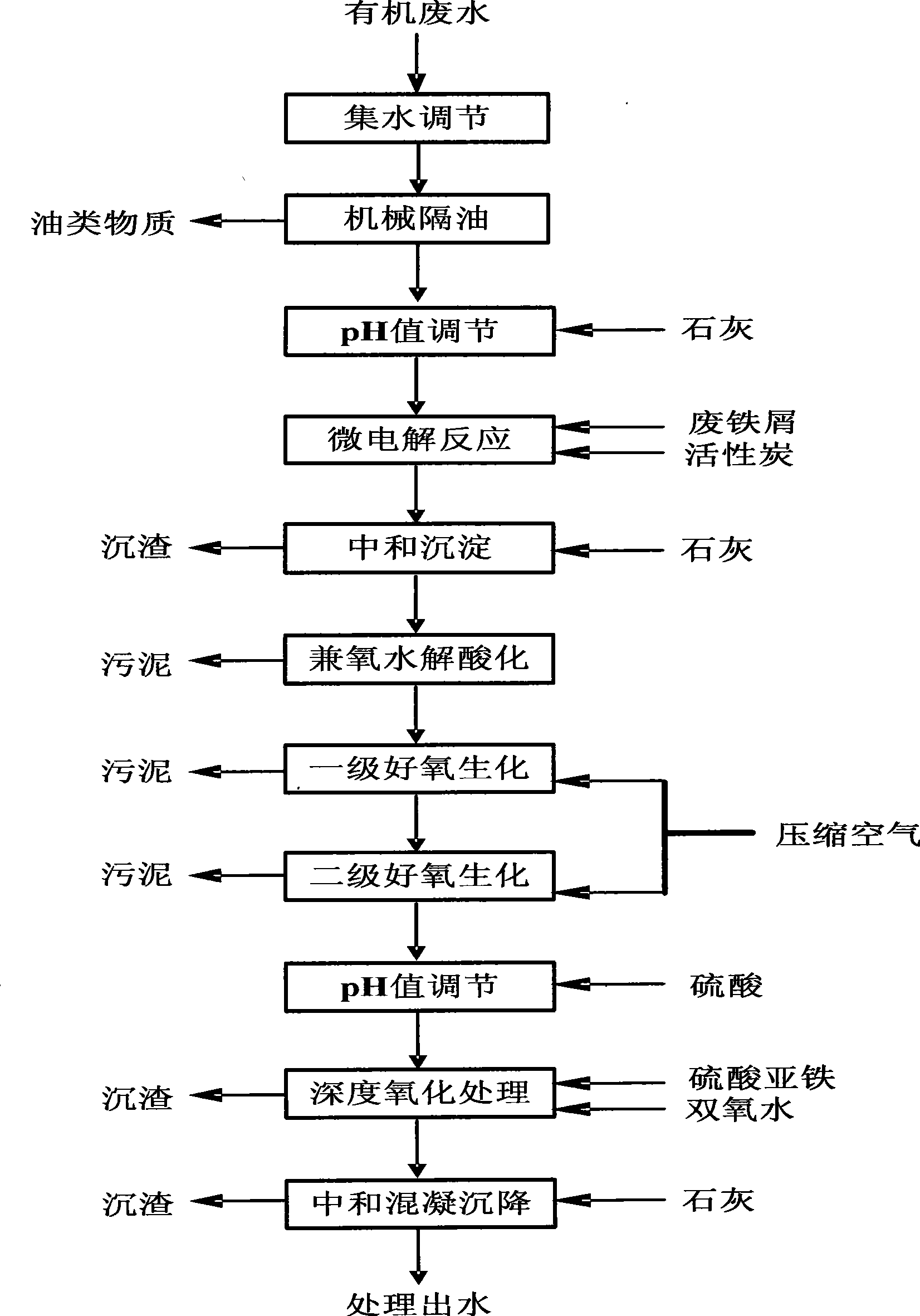

[0025] Such as figure 1 As shown, the treatment process containing high-concentration p-toluidine refractory organic wastewater includes the following sequential process steps:

[0026] a. Physicochemical pretreatment. Firstly, the organic wastewater is subjected to water collection adjustment and mechanical oil separation process to separate and remove oily substances, then add lime to adjust the pH value to 3-4, and then add iron and carbon for micro-electrolysis Reaction, the reaction time is 4 to 6 hours, and finally lime is added for neutralization and precipitation, and the pH value rises to 7 to 8 to remove most of the COD of the wastewater, improve the biodegradability of the wastewater, and separate the sediment;

[0027] b. Microbial anaerobic hydrolysis and acidification treatment, the waste water that has undergone physical and chemical pretreatment is passed into the cultivated and domesticated microorganisms for facultative hydrolysis and acidification, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com