Preparation method of waterproof fabric

A waterproof fabric and fabric technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of inability to achieve protective effect, non-fitting of rubber layer and fabric layer, poor use effect, etc., and achieve excellent waterproof performance, sensitive use, good reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to a preparation method of waterproof gloves, specifically comprising the following steps:

[0033] Step 1. Prepare waterproof emulsion

[0034] Add the nanometer fluorocarbon resin polymer into water under stirring conditions to obtain a mixed solution, the concentration of the nanometer fluorocarbon resin polymer is 30g / L; add glacial acetic acid or citric acid dropwise to the mixed solution until the pH value is 5, i.e. Get a waterproof lotion.

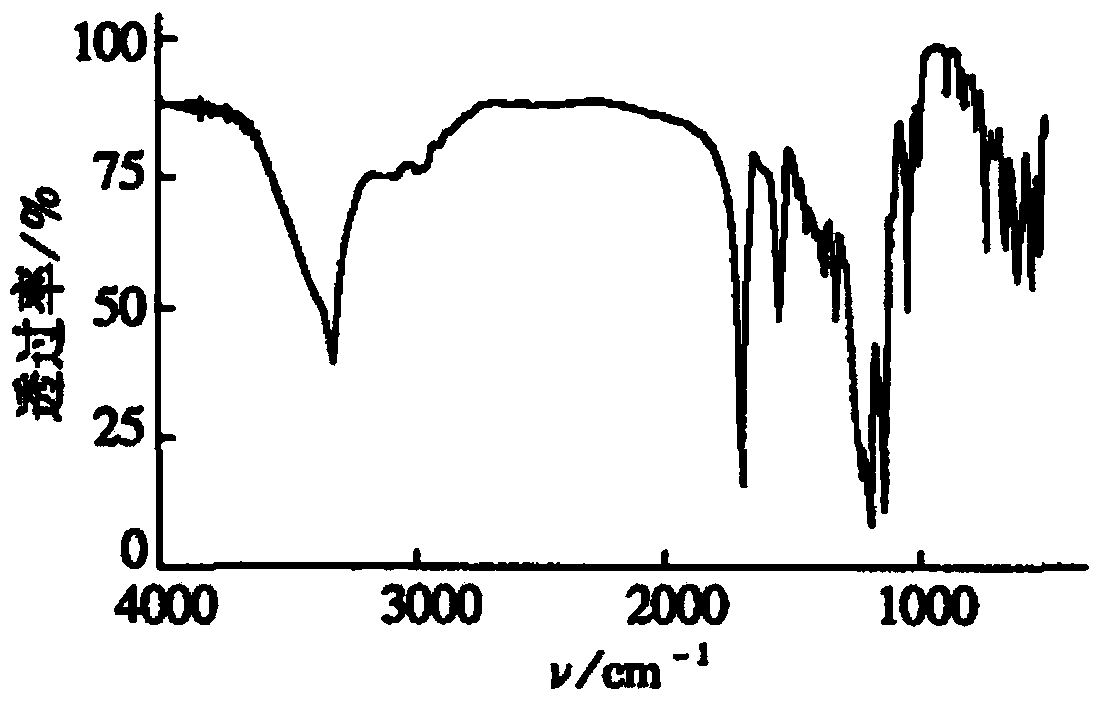

[0035] The nano-fluorocarbon resin polymer in this embodiment is self-made, and the specific methods are as follows:

[0036] Add 1.74g (0.01mol) of 2,4-toluene diisocyanate, 4ml of anhydrous methyl isobutyl ketone and 1 drop of dibutyltin dilaurate (catalyst) in a four-necked flask to dry N 2 Protect, heat up to 65-70°C, slowly add 4.57g (0.01mol) of N-hydroxyethyl perfluorooctylamide and 12ml of anhydrous methyl isobutyl ketone solution dropwise, dropwise for 1h, and maintain this state after drop...

Embodiment 2

[0046] This embodiment relates to a preparation method of waterproof gloves, specifically comprising the following steps:

[0047] Step 1. Prepare waterproof emulsion

[0048] Add the nanometer fluorocarbon resin polymer into water under stirring conditions to obtain a mixed solution, the concentration of the nanometer fluorocarbon resin polymer is 30g / L; add glacial acetic acid or citric acid dropwise to the mixed solution until the pH value is 5, i.e. Get a waterproof lotion.

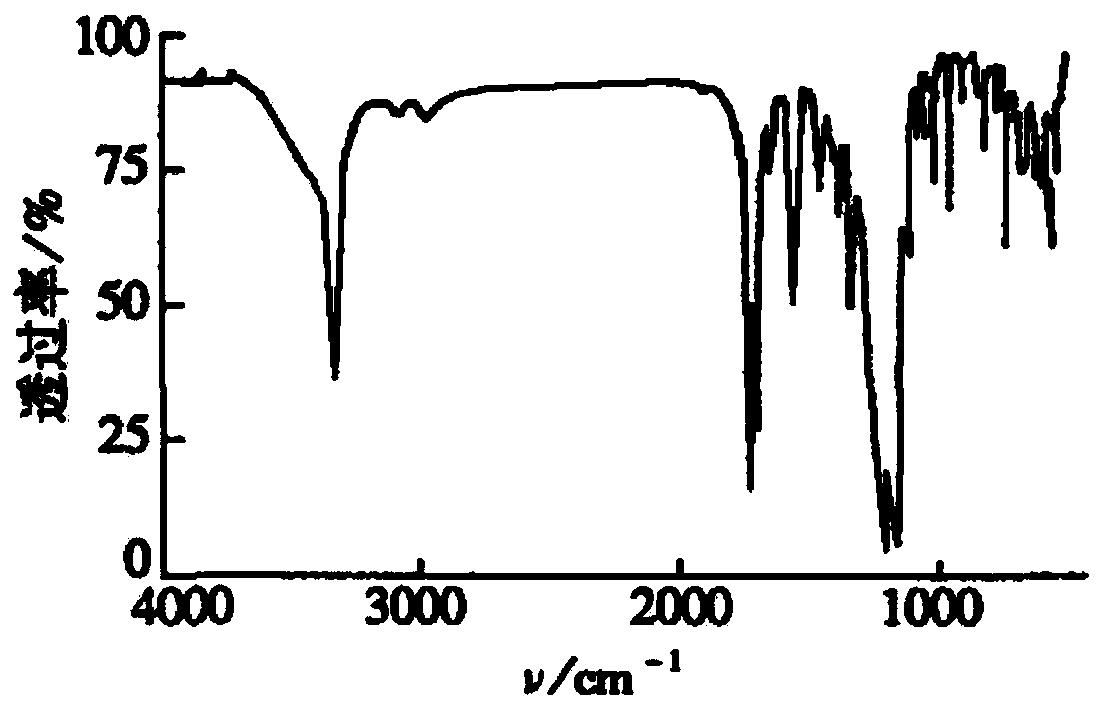

[0049] The nano-fluorocarbon resin polymer in this embodiment is a self-made organosilicon-modified nano-fluorocarbon resin polymer, and the specific preparation method is as follows:

[0050] The nano-fluorocarbon resin polymer prepared by the method of Example 1 is mixed with the silane coupling agent KH-570, and a coupling reaction occurs to obtain a silicone-modified nano-fluorocarbon resin polymer; the amount of the silane coupling agent 5wt.%.

[0051] Step 2. Glove dipping

[0052] Wash / soa...

Embodiment 3

[0060] This embodiment relates to a preparation method of waterproof gloves, specifically comprising the following steps:

[0061] Step 1. Prepare waterproof emulsion

[0062] Add the nanometer fluorocarbon resin polymer into water under stirring conditions to obtain a mixed solution, the concentration of the nanometer fluorocarbon resin polymer is 30g / L; add glacial acetic acid or citric acid dropwise to the mixed solution until the pH value is 5, i.e. Get a waterproof lotion.

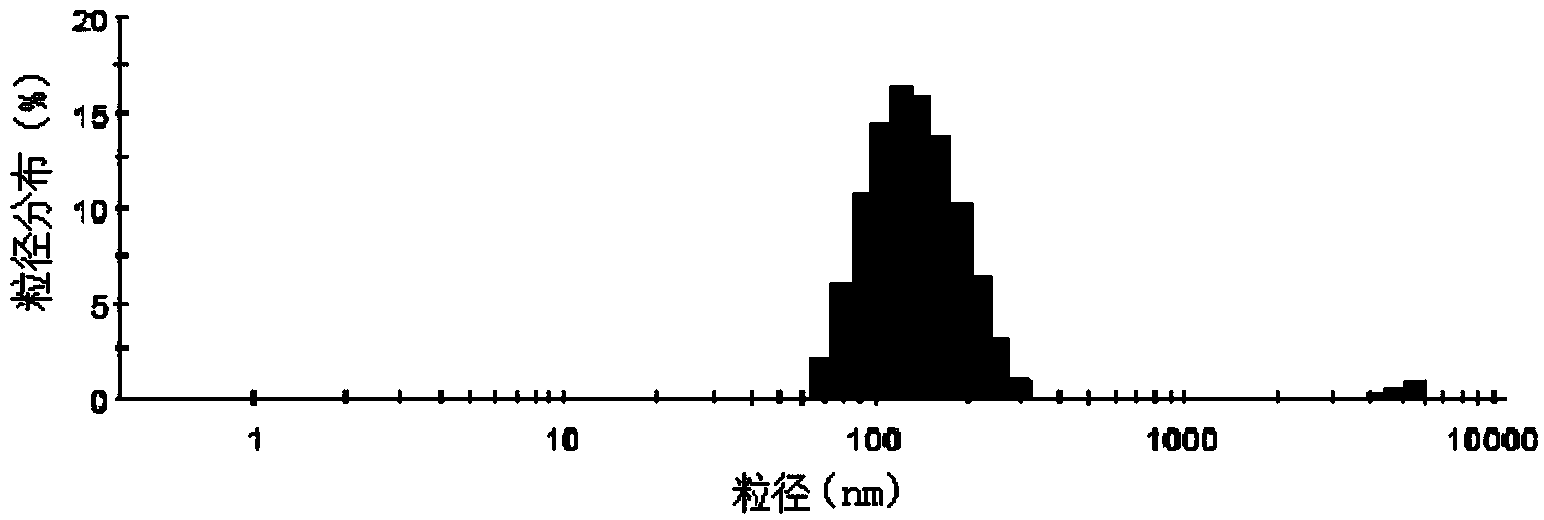

[0063] The nanometer fluorocarbon resin polymer in the present embodiment is CF-1114 fluorocarbon resin, is made of molecular size less than 10 -9 Fluorocarbon polymer colloids of 80-185nm that are agglomerated from m particles.

[0064] Step 2. Glove dipping

[0065] Wash / soak the gloves in water to wash off the floating color, dirt and hydrophilic groups on the surface of the fabric, so that the fabric and the waterproof agent have a better hinge reaction at high temperature; spin dry to quickly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com