In-line common rail fuel feed pump capable of controlling low-pressure fuel inlet amount

An in-line, oil supply pump technology, applied in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of large volume, easy high pressure leakage, high oil temperature, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

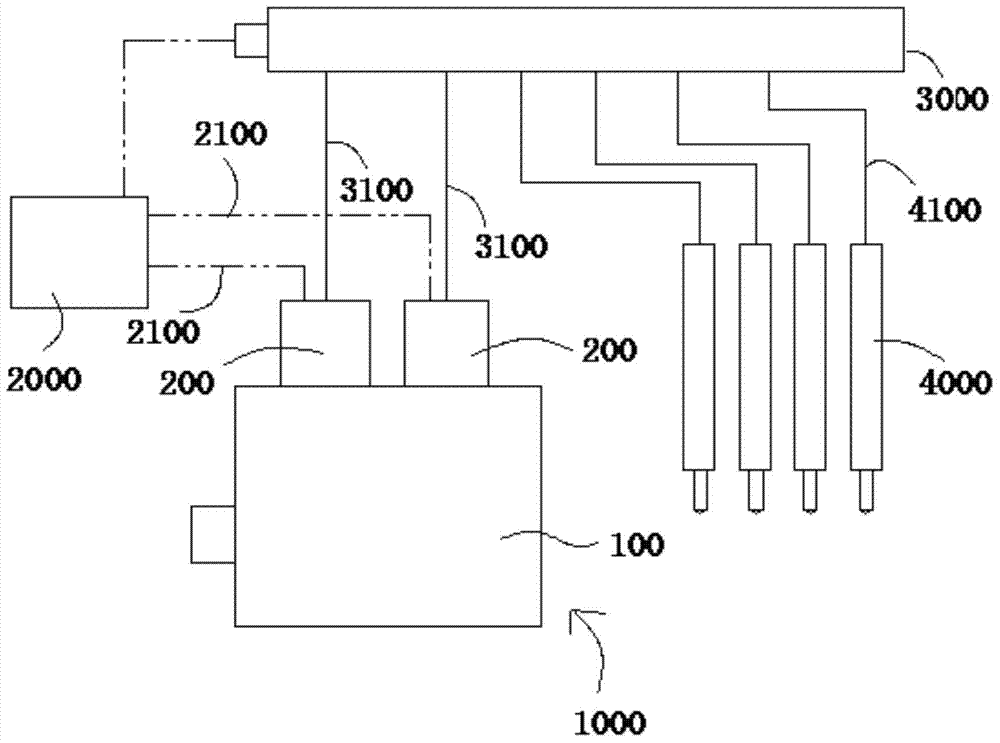

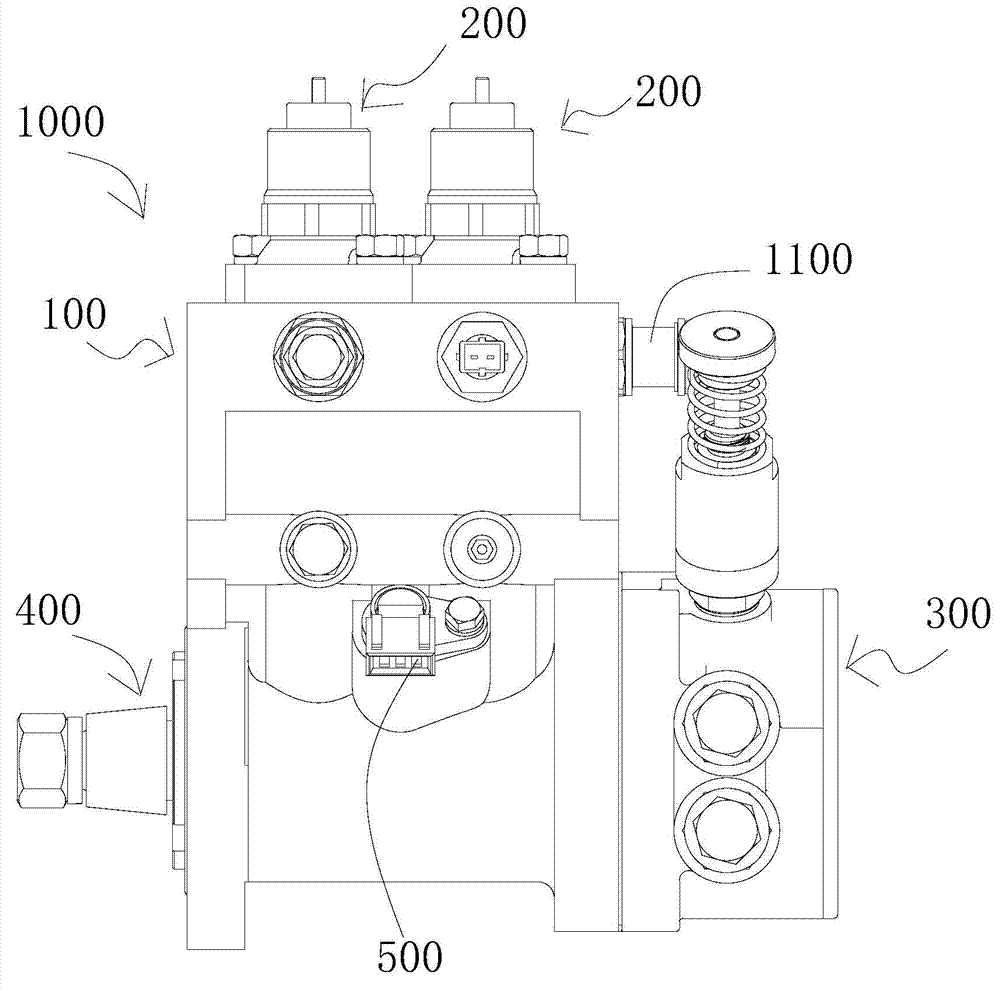

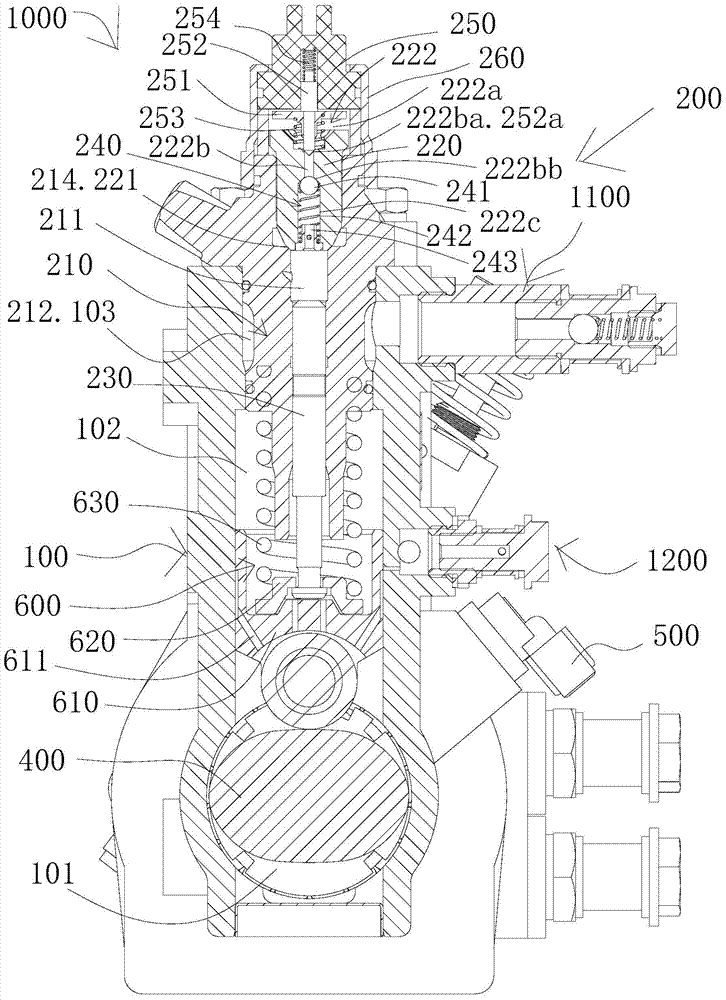

[0032] see figure 1 and figure 2 The shown in-line common rail oil supply pump 1000 for controlling low-pressure oil inlet includes a pump body 100 and several common rail single pumps 200 arranged side by side on the pump body 100, and the side of the pump body 100 is connected to the oil delivery pump 300 , the pump body 100 is provided with a drive cam 400 for driving the common rail unit pump 200 to work, and the axis of the drive cam 400 is perpendicular to the axes of several common rail unit pumps 200 . The side of the pump body 100 is provided with a cam position sensor 500 for monitoring the phase of the drive cam 400, the cam position sensor 500 is connected to the ECU unit 2000 through a signal cable 2100, and the side wall of the pump body 100 is provided with an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com