Air door device provided with turning plate for power station and blocking method

A damper device, flap door technology, applied in the combustion method, valve configuration, exhaust gas device and other directions, to achieve the effect of easy maintenance, easy operation, and good isolation of the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

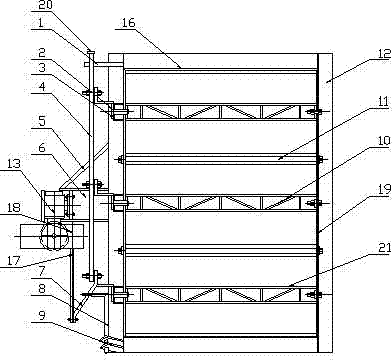

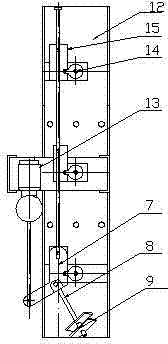

[0021] A flap damper device for a power station, its composition includes: the flap door 10 is connected with a door frame 12, the door frame is connected with a bearing seat 3, the bearing seat is connected with a ratchet shaft 2, the The ratchet shaft is connected with the connecting rod shaft connecting plate 15, the connecting rod shaft connecting plate is connected with the connecting rod shaft 4, the connecting rod shaft connecting plate is connected with the hinge shaft 8, and the hinge shaft and the hinge shaft are installed Plate 9 is connected, the hinge shaft mounting plate is connected with the door frame, the connecting rod shaft connecting plate is connected with the cylinder piston 17, the cylinder piston is connected with the air pump 18, and the air pump is connected with the motor 13 , the door frame is connected with a set of partitions 11 .

Embodiment 2

[0023] According to the flap damper device for the power station described in Embodiment 1, there is a sealing strip 16 inside the door frame, reinforcing ribs 19 are installed on both sides of the door frame, and the partition is connected to the door frame The sealing strip is installed at the place, the locking piece is arranged on the connecting rod shaft, the connecting rod shaft is connected with the connecting rod shaft guide block, and the connecting rod shaft guide block is connected with the door frame.

Embodiment 3

[0025] According to the flap damper device for a power station described in embodiment 1 or 2, there are bearings in the bearing seat, the partition plate is made of stainless steel, and the edge is grooved with a sealing strip, and the air pump There is a hand wheel on the top, the motor is connected with the motor base, the motor base is connected with the door frame, and the motor base has reinforcing ribs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com