GaN-based device isolation method

A device isolation and metal film technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of device reliability decline, low leakage, and high resistance, and achieve low defect density, low leakage, and high resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

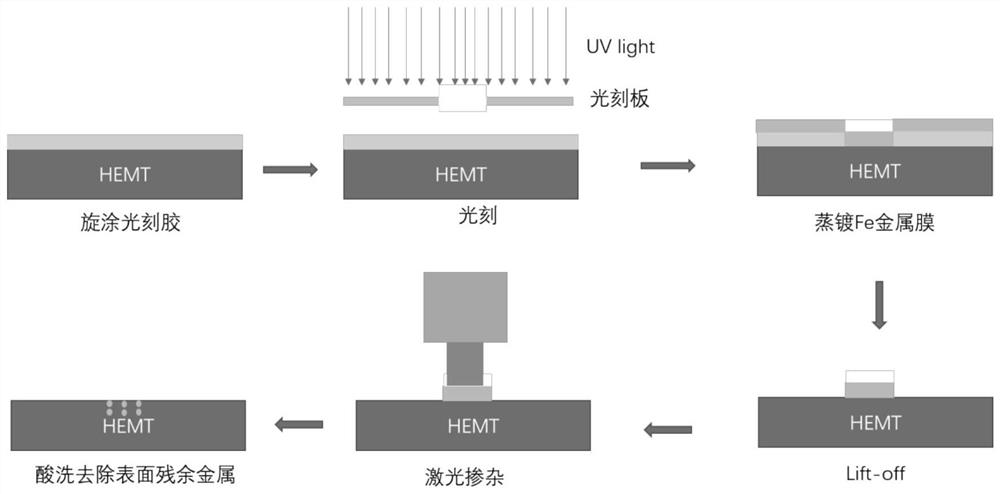

[0032] see figure 1 , the present invention provides a method for GaN-based device isolation, comprising the following steps:

[0033] Step 1): Expose the area where device isolation needs to be done on the surface of the sample by photolithography;

[0034] Step 2): Evaporate a layer of Fe metal film on the surface of the sample, the purity of the Fe source used is 99.999%, and the electron beam pressure is 10 -6 Torr, evaporation rate 0.5-3nm / min, Fe metal film thickness 1-20nm;

[0035] Step 3): The Lift-off process removes the excess Fe metal film, leaving the area that needs to be isolated to cover the Fe metal film;

[0036] Step 4): The Fe metal film is irradiated with laser pulses, the wavelength of the laser used in the experiment is 1030nm, the pulse width is 0.13ps, the average power is 30-70mW, and the laser repetition frequency is 2000Hz;

[0037] The high-energy laser pulse melts the sample locally, the Fe element diffuses into the sample, and Fe is incorporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com