Method and system for producing hydrogen oil by converting ultrahigh-temperature medical solid waste

A technology of ultra-high temperature and hydrogen oil, applied in the field of hydrogen energy, can solve the problems of large-scale application of liquid organic hydrogen storage technology at normal temperature and pressure, poisoning fuel cells, poisoning fuel cells, etc., achieve good environmental protection and economic value, and reduce storage costs. and transportation costs, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

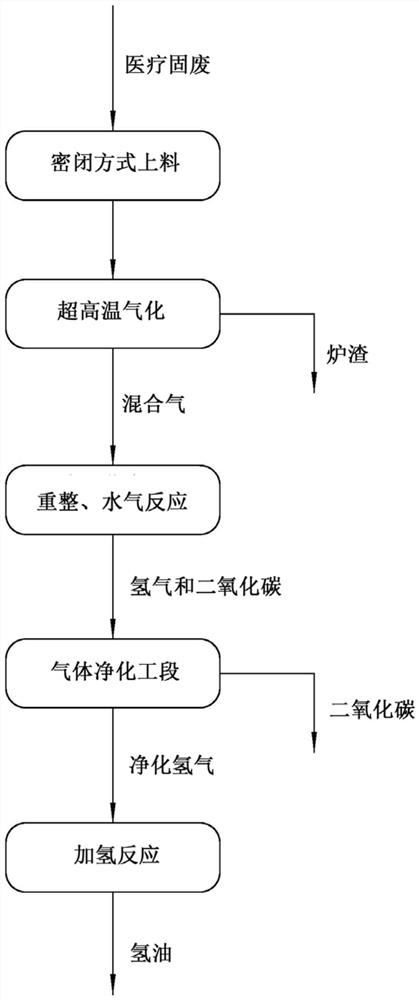

[0043] from Figure 1As can be seen from the flow chart of the method of converting ultra-high temperature medical solid waste into hydrogen oil, the medical solid waste is recovered after the integrated box of collection, storage and transport is first used, and the material is loaded in a closed manner. The integrated box of storage and transfer is a closed cubic box made of metal on four sides and plastic on both sides. Sealing can be carried out by means of negative pressure.

[0044] After the medical solid waste is sealed and compressed, the medical solid waste compressed into pieces is heated, dried and pyrolysis to obtain pre-treated medical solid waste and pyrolysis gas, and the pyrolysis temperature is 800 °C. The pre-treated medical solid waste and pyrolysis gas are gasified at ultra-high temperature, the gasification temperature is 1000 °C, and the gasification process adopts indirect heating to generate a mixture of gas.

[0045] Under the action of a highly selective ...

Embodiment 2

[0058] After the medical solid waste is recovered by the integrated box of collection, storage and transfer, the closed feeding method is adopted. The integrated box of storage and transfer is a closed cubic box made of metal on four sides and plastic on both sides.

[0059] The medical solid waste is compressed and gasified at ultra-high temperature, the gasification temperature is 1600 °C, and the gasification process adopts indirect heating. Molten slag and gas mixtures are generated.

[0060] Under the action of a highly selective reaction catalyst, the mixture first undergoes a reforming reaction to generate crude syngas, and then hydrogen and carbon dioxide are prepared by the water-gas transformation reaction, and the crude syngas includes CO and H 2 、CO 2 。 The reaction temperature of water-gas conversion is 500 °C. The highly selective reaction catalyst is a supported catalyst with an active component of WO 3 , the carrier is activated carbon.

[0061]Hydrogen is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com