Patents

Literature

56results about How to "Achieve the purpose of isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

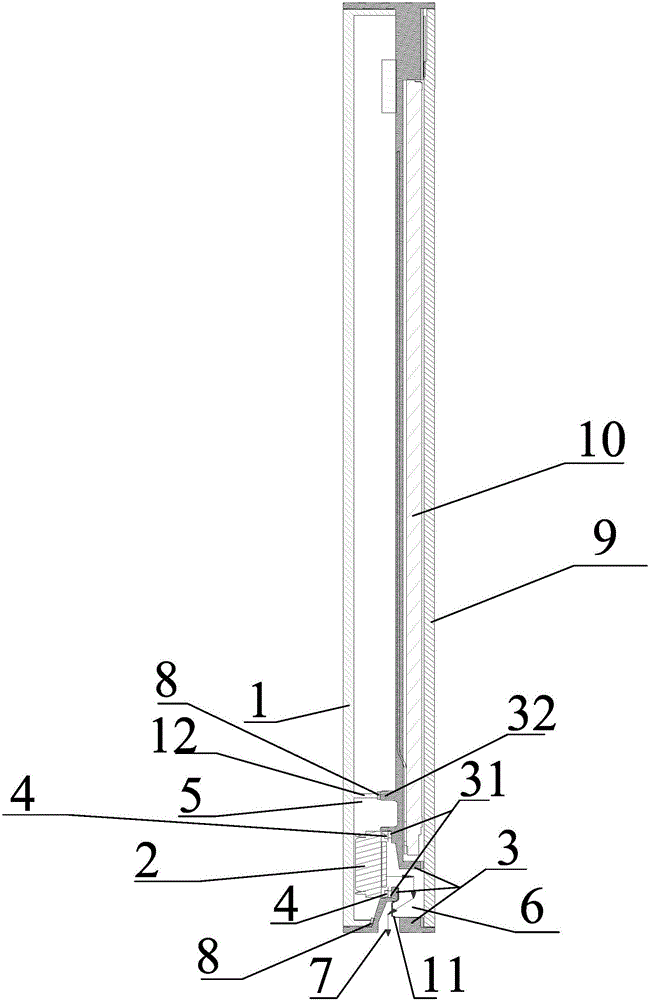

Medium and high temperature heat collecting tube for internal concentrated light and volume reduction solar energy and its manufacturing method

ActiveCN102278832AImprove heat collection efficiencyIncrease luminous energy densitySolar heat devicesSolar thermal energy generationVolume reductionSolar thermal collector

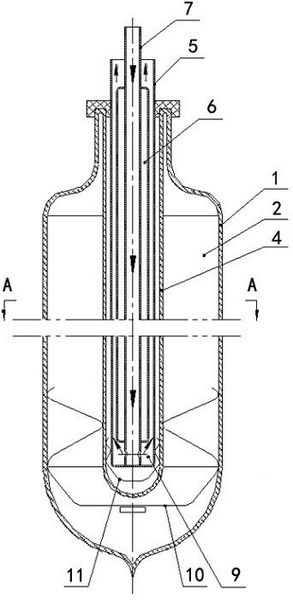

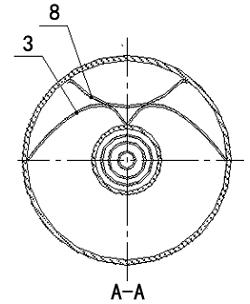

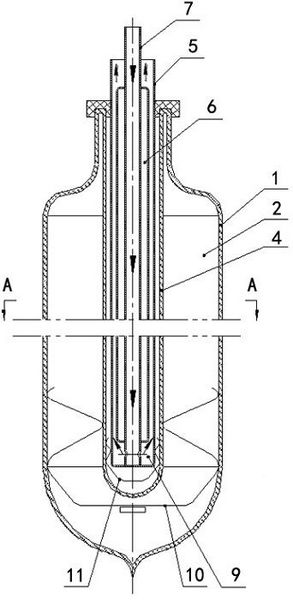

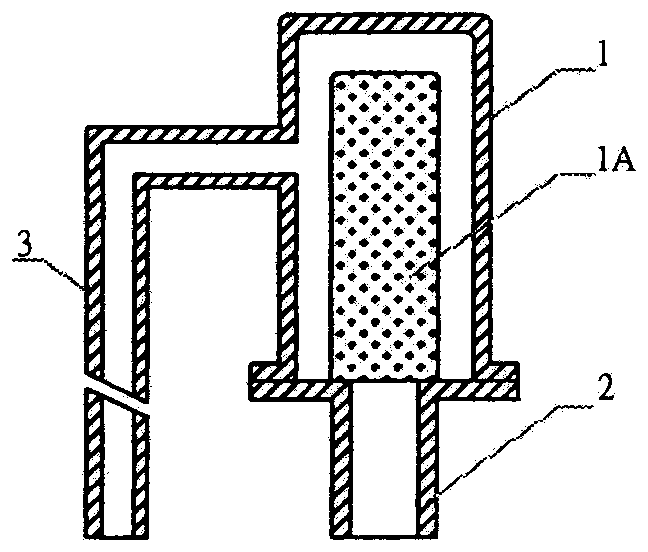

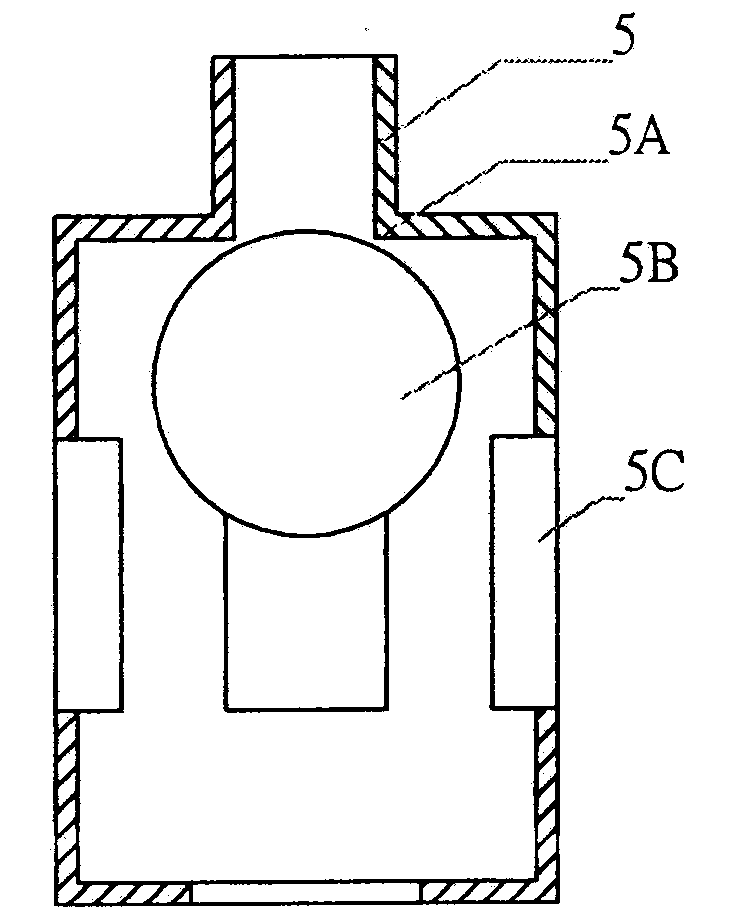

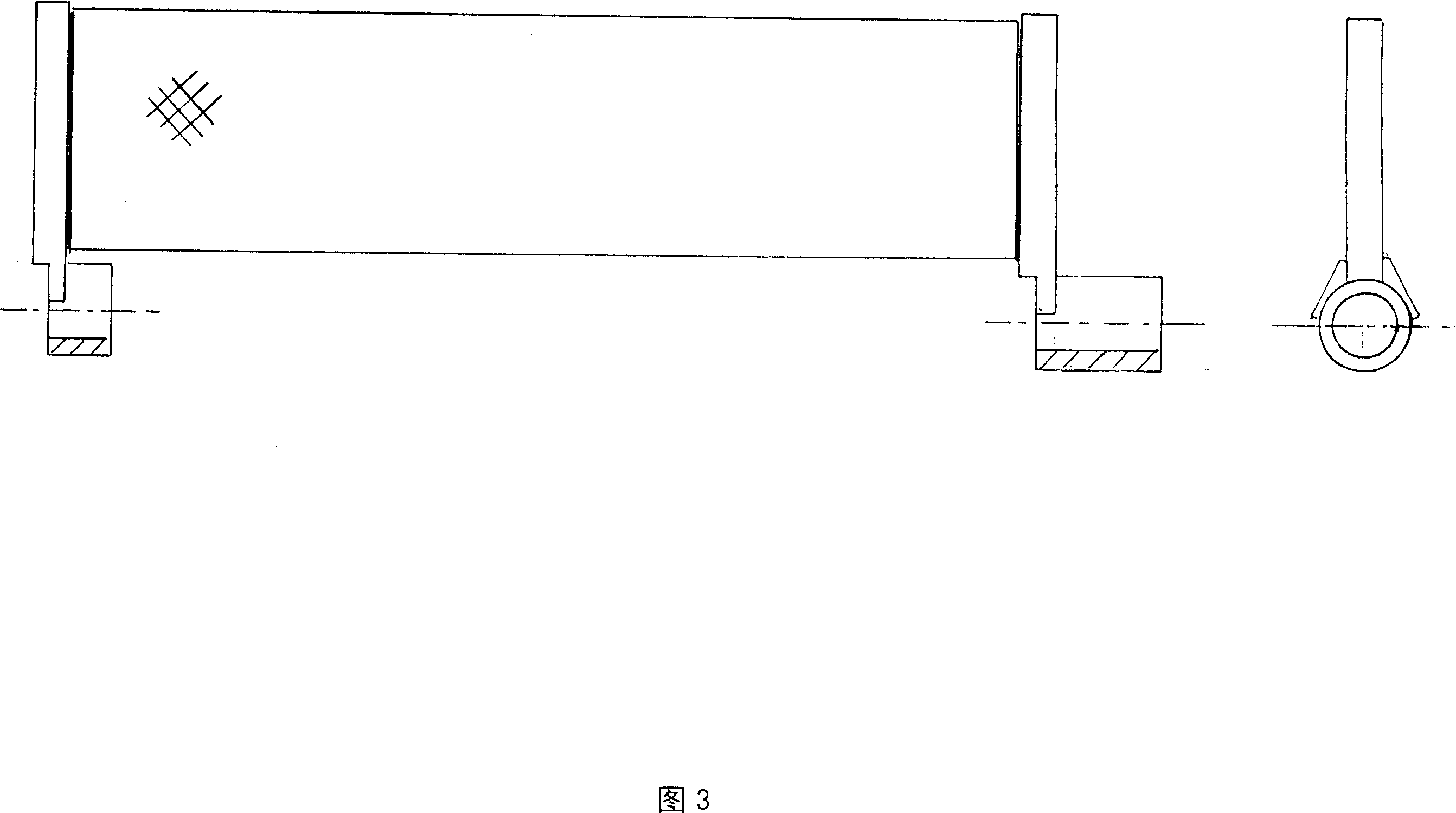

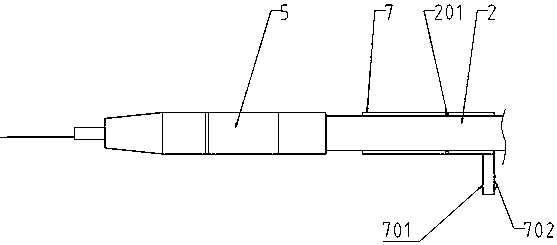

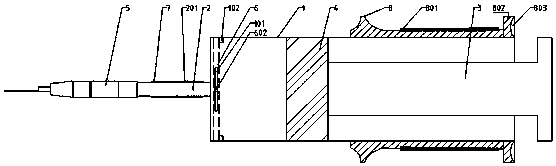

The invention relates to an internal-condensation capacity-reducing solar medium and high temperature heat collection pipe and a method for manufacturing the same. The heat collection pipe comprises a vacuum internal-condensation solar heat collector, wherein the vacuum internal-condensation solar heat collector consists of an outer cover tube which is made of a light-transmitting material, a heat absorption tube which is coaxial with the outer cover tube and a composite parabolic reflecting plate which is assembled between the outer cover tube and the heat absorption tube; a heat energy conductor is arranged in the vacuum internal-condensation solar heat collector; the heat energy conductor consists of a metal sleeve, a metal flow guide cavity tube which is assembled in the metal sleeve, and heat conduction media which are filled in the metal sleeve and the metal flow guide cavity tube; the metal sleeve is inserted into an internal cavity of the heat absorption tube and tightly contacted with the heat absorption tube; and a heat conduction heat medium transmission path is formed between the metal flow guide cavity tube and the metal sleeve. The preparation steps of the high temperature heat collection pipe are as following: manufacturing focus solar collector in vacuum, processing heat sensor, and then assembling and moulding. The internal-condensation capacity-reducing solar medium and high temperature heat collection pipe is high in heat collection efficiency, high in heat transfer speed and safe, and can convert solar energy into a medium and high temperature heat source for use.

Owner:河北光源太阳能有限公司

Insulator for bare-packing and sintering ceramics to be stacked in multi-layered manner and application method thereof

The invention relates to an insulator for bare-packing and sintering ceramics to be stacked in a multi-layered manner and an application method thereof. The insulator comprises the following raw materials in parts by weight: 35-60 parts of quartz particles with 32-100 meshes, 40-65 parts of calcined Al2O3 or quartz particles with 100-140 meshes and 0.5-2 parts of peach gum or carboxyl methyl cellulose (CMC). The application method comprises the following steps during the preparation: firstly, dissolving the peach gum or the carboxyl methyl cellulose by using water with a weight ratio of 6-20 times, then adding the proportioned other raw materials, and finally, adding an appropriate amount of water to mix into thin paste. When in use, the insulator is sprayed, coated or brushed on the surfaces of stacked parts of ceramic tire products; and after the insulator is naturally aired, the same shape or different shapes of a plurality of layers of or a plurality of ceramic tire products are vertically stacked on sintered kiln furniture on a same plane to be sintered, and the sintering temperature is 1200-1280 DEG C. After the ceramics are sintered, viscose compositions in the ceramics aredecomposed and evaporated, and the quartz particles and the calcined Al2O3 particles are only remained among the ceramic tire products and can not be melted or bonded with ceramic tires, so that the purpose of dividing and separating the vertically-stacked and sintered ceramic tire products is achieved.

Owner:潮州市美地陶瓷有限公司

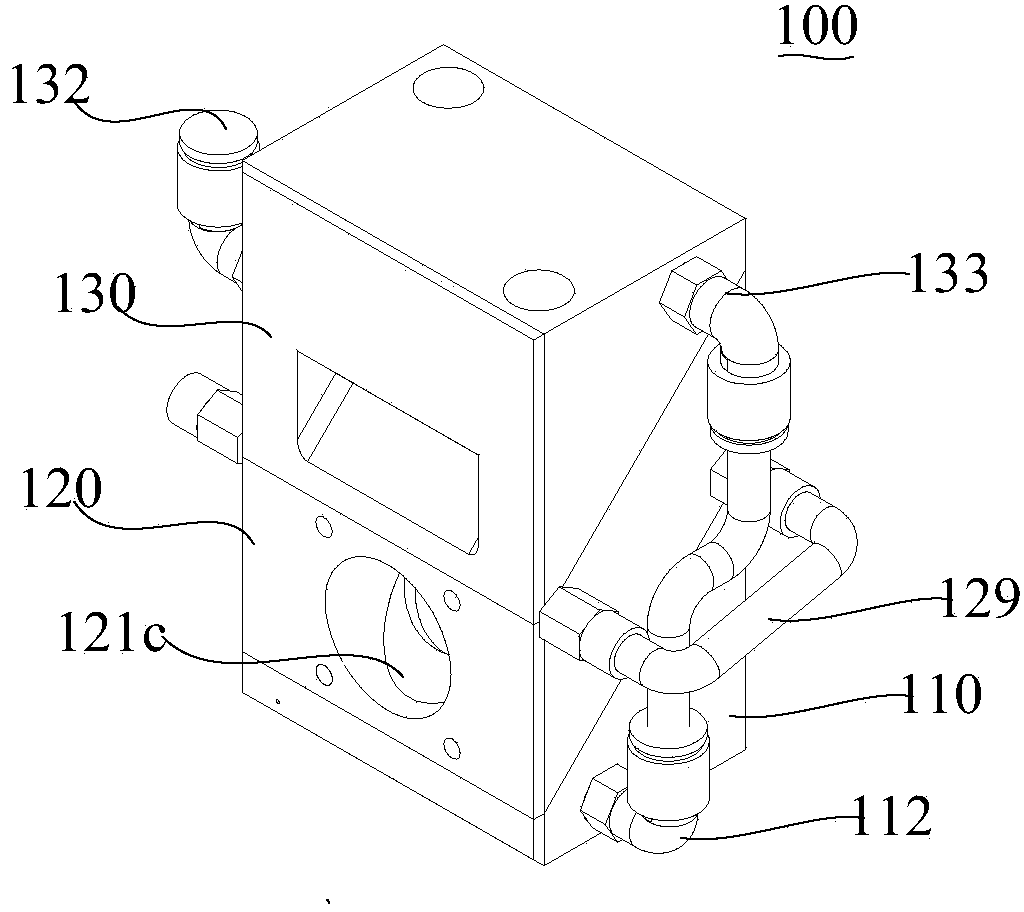

Water quality controller of water tank

ActiveCN103669489AAchieve the purpose of isolationGive full play to the disinfection effectService pipe systemsWater mainsPositive pressureWater quality

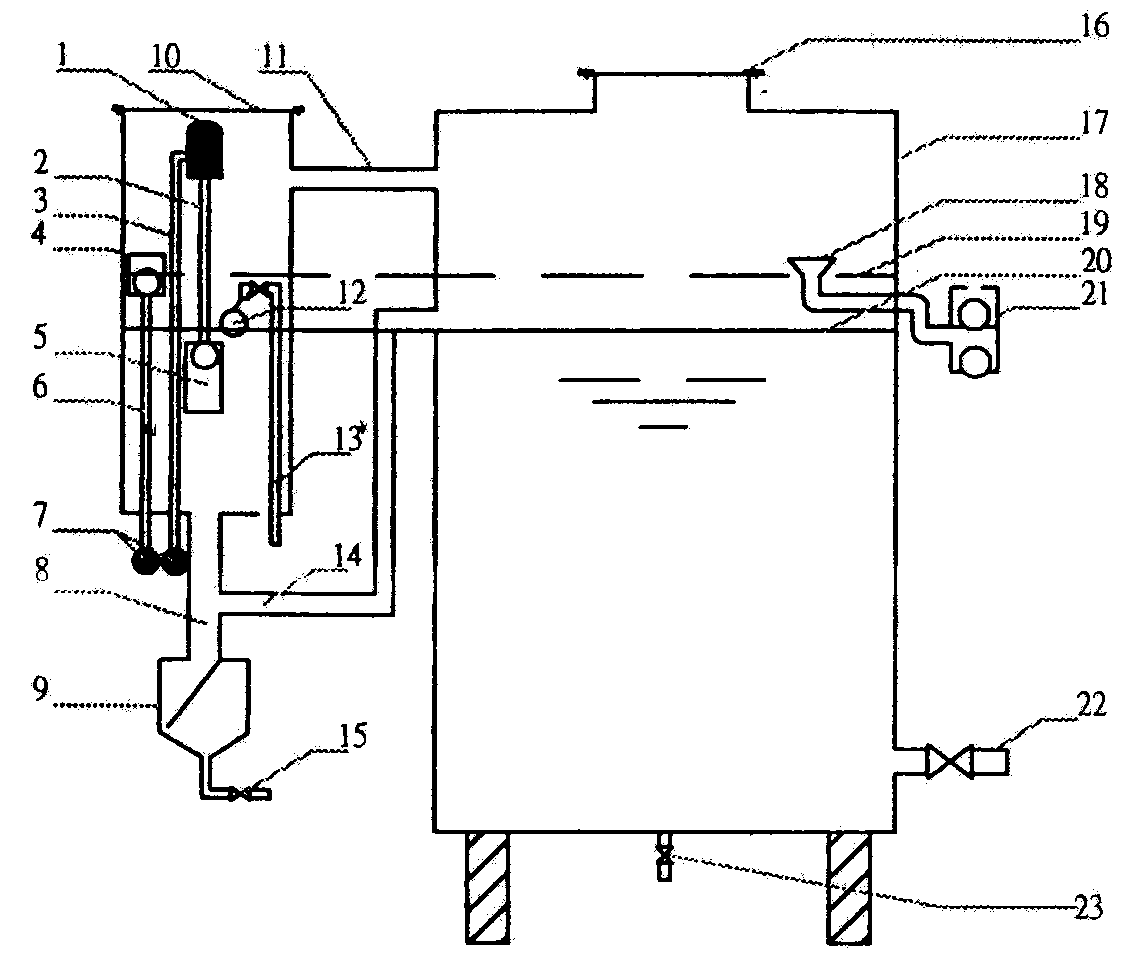

After a water quality control of a water tank is connected with the slightly-improved water tank, the water tank is changed into an expanded pipeline, and therefore secondary pollution is effectively avoided. Power of ball valves in the controller depends on energy provided by water inlet and water consumption of a pipe network. A filter, a chlorine control ball valve, a water overflow ball valve, a water inlet pipe, a water outlet pipe, a breathing pipe and a deep hole dirt storage tank are arranged in a tank body. The water quality controller and the water tank are connected into a whole through a communicating pipe. A manhole of the water tank is sealed, a safety valve is installed on an overflow pipe, and therefore expansion and shrinking of the tank are avoided. Through the chlorine control valve, an air chamber in the tank can be kept at micro-positive pressure, and therefore free chlorine does not easily escape out of the tank and can fully play the disinfection role. When water inlet is larger than water outlet, air, containing free chlorine, in the tank is exhausted outwards to back flush a disinfection filter element, and therefore efficiency of the filter is improved, and the service life of the filter is prolonged. A water flow slow flow zone and the deep hole dirt storage tank are arranged on the controller, and a dead water zone is moved forwards to the controller. The goal of avoiding secondary pollution of tap water is achieved without consuming electricity, adding disinfector or conducting filtering.

Owner:上海沥源流体科技有限公司

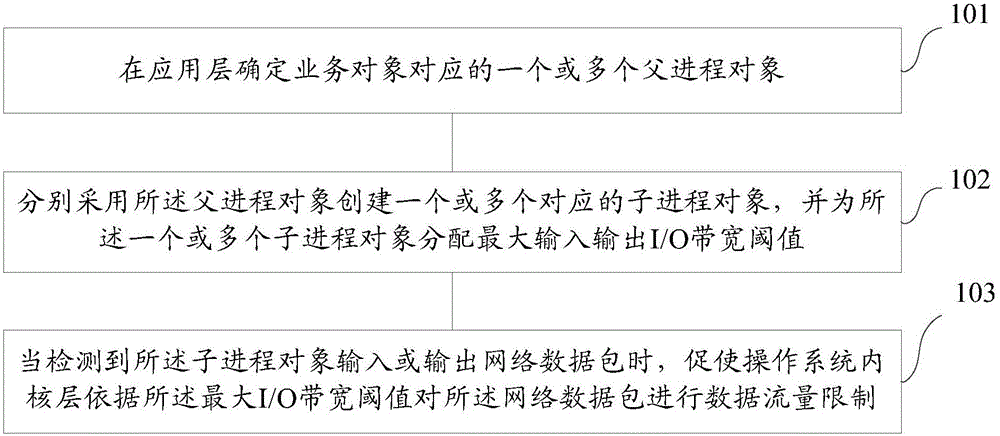

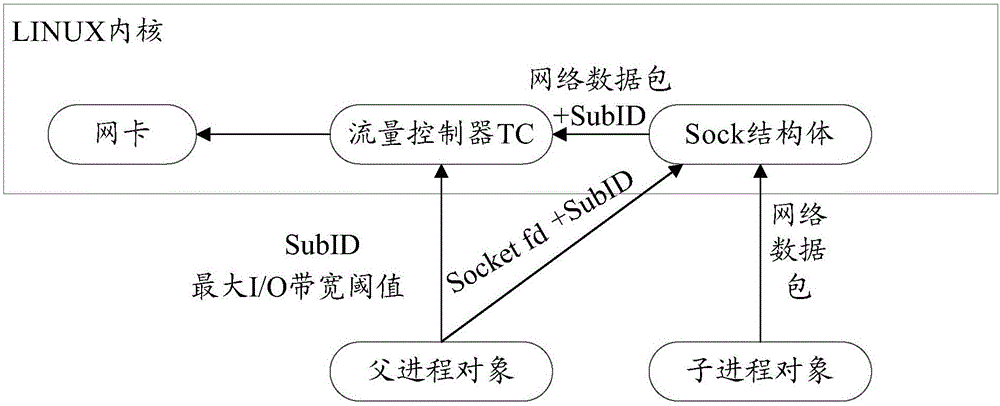

Data flow limitation method and system

ActiveCN106411558ACause stabilityMeet network needsData switching networksOperational systemFlow limitation

Owner:ALIBABA GRP HLDG LTD

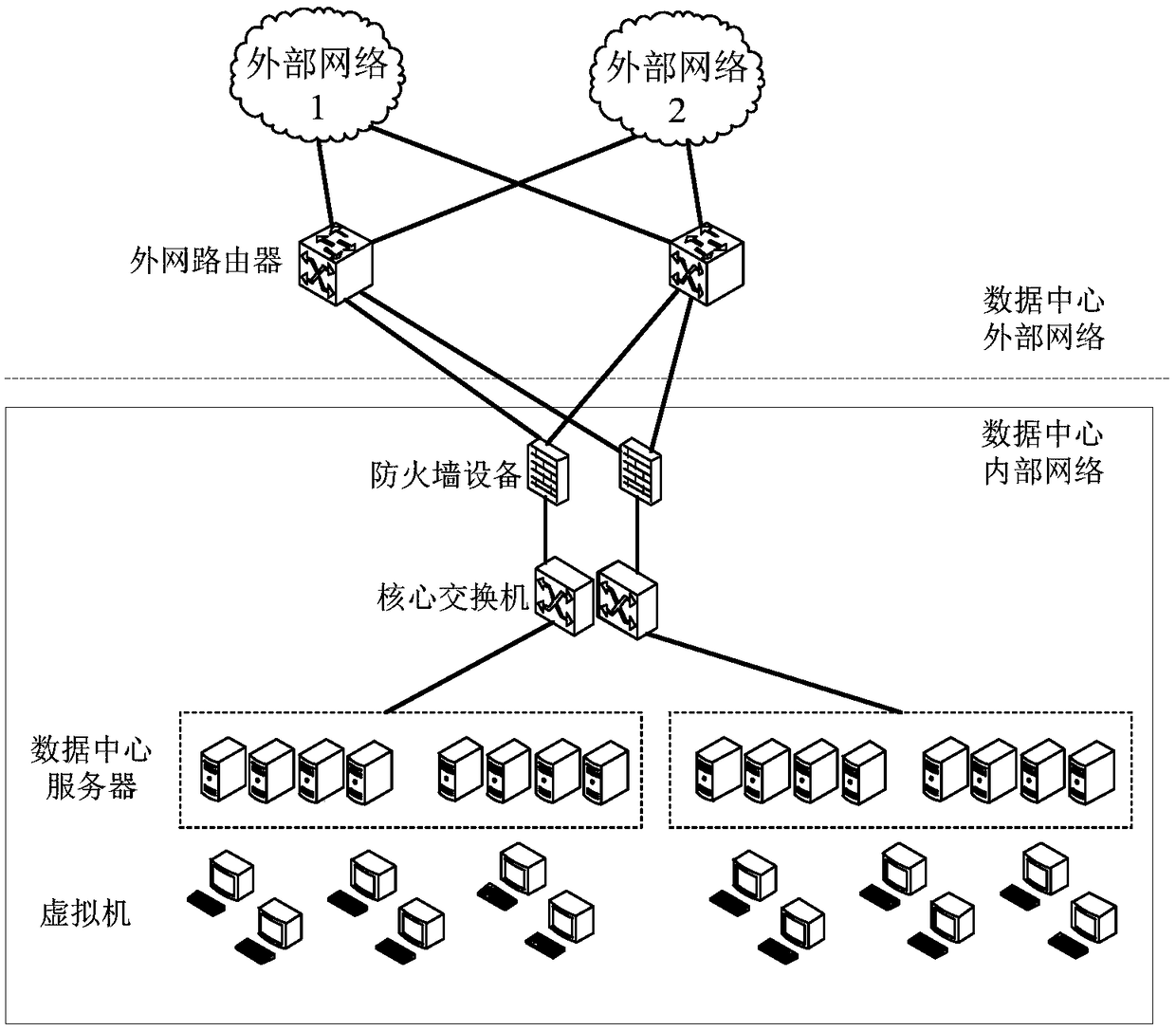

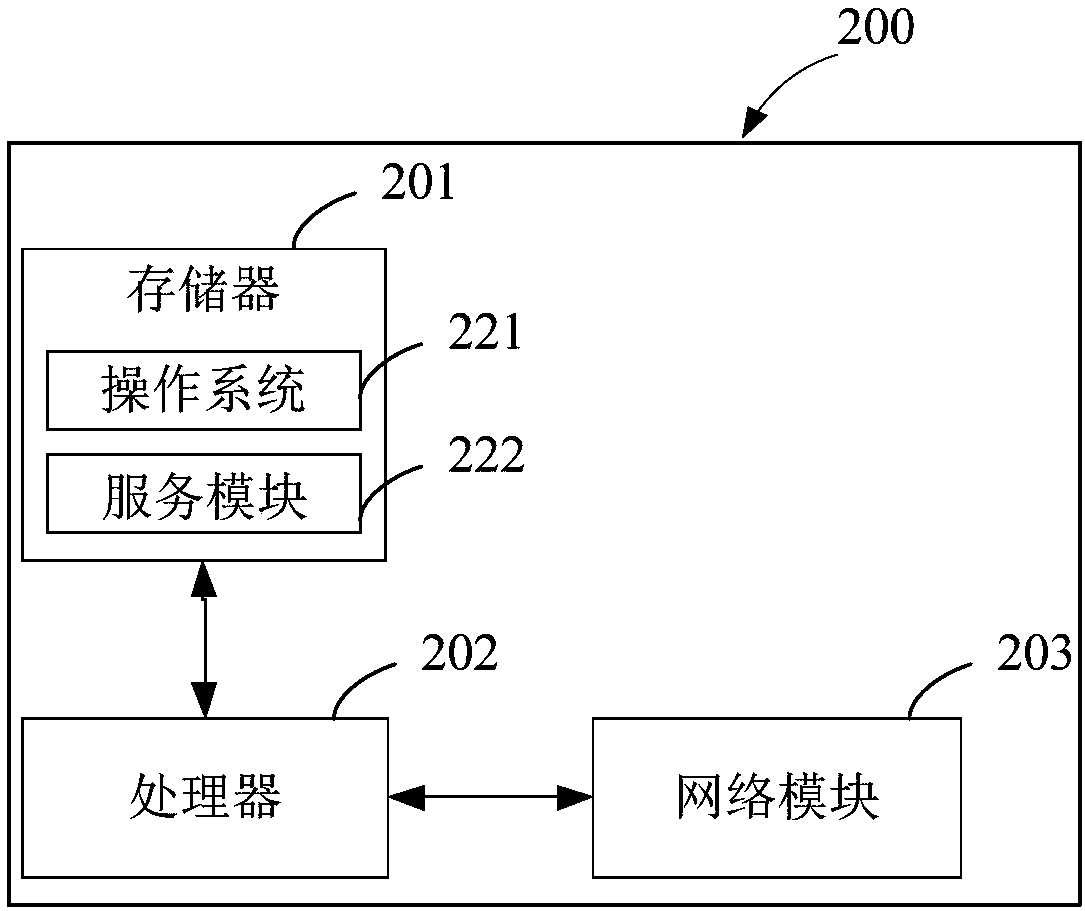

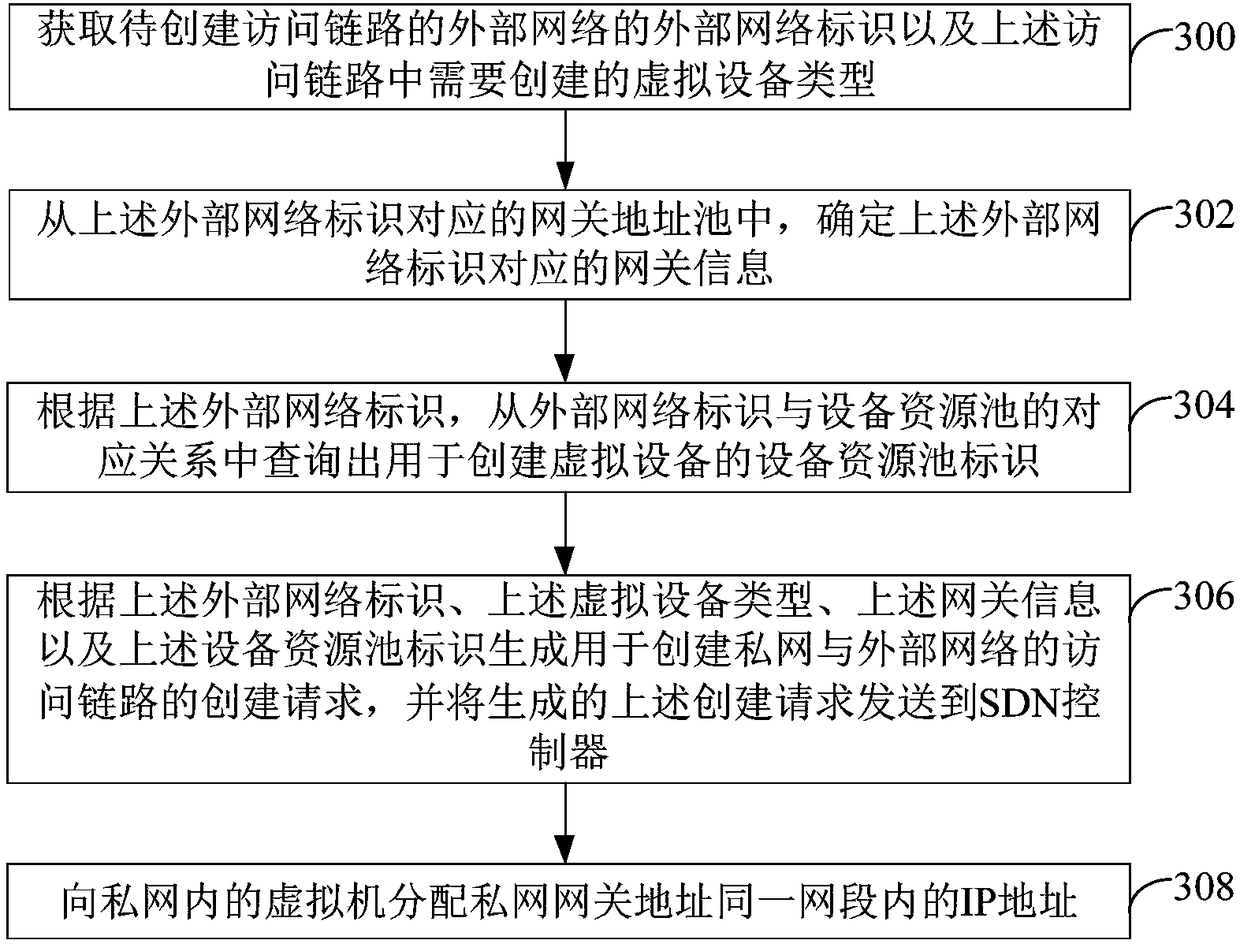

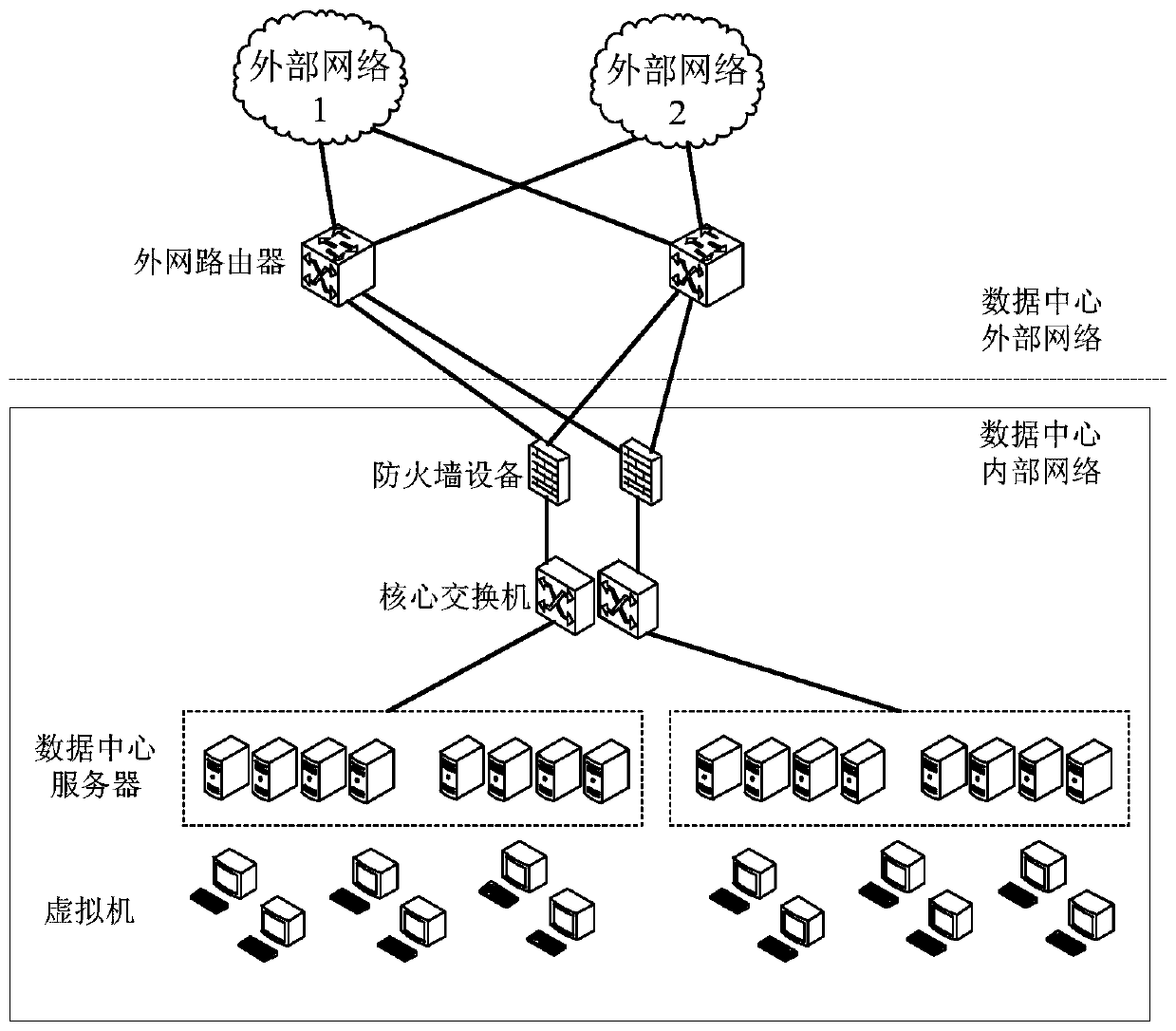

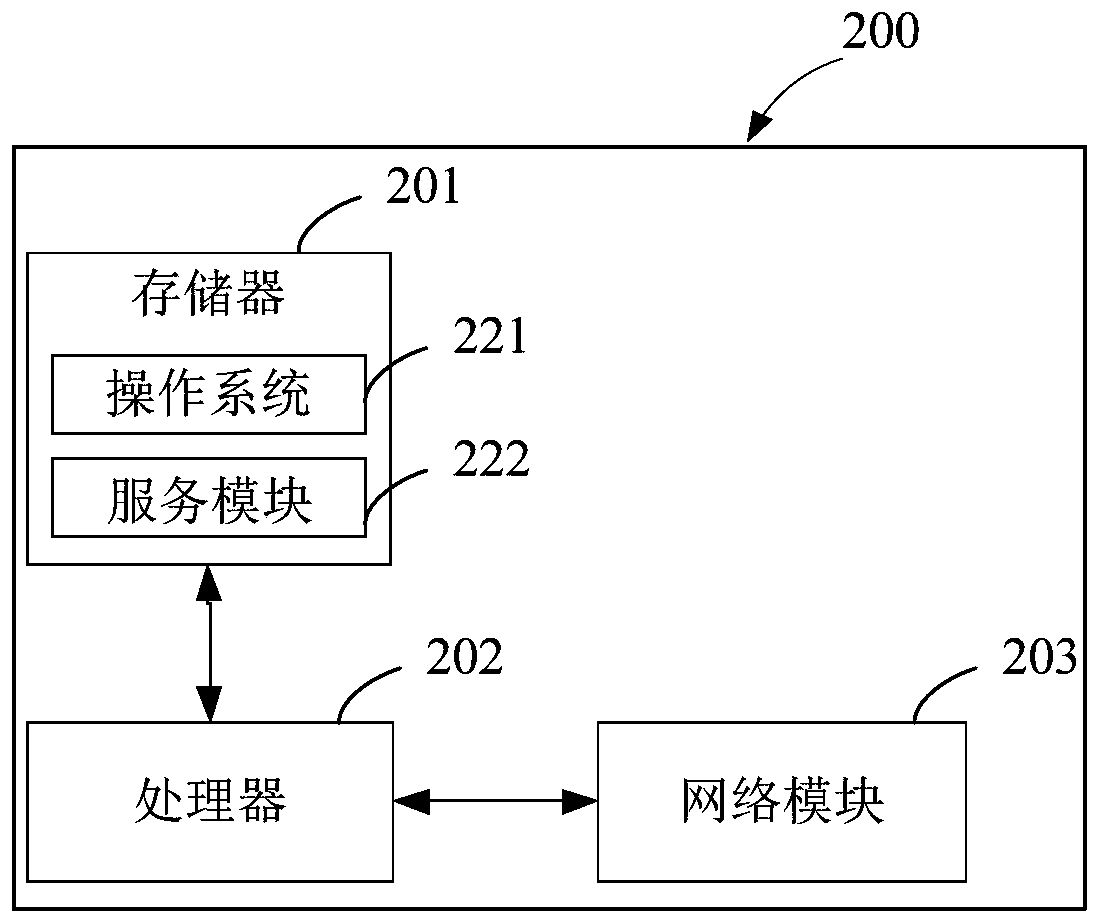

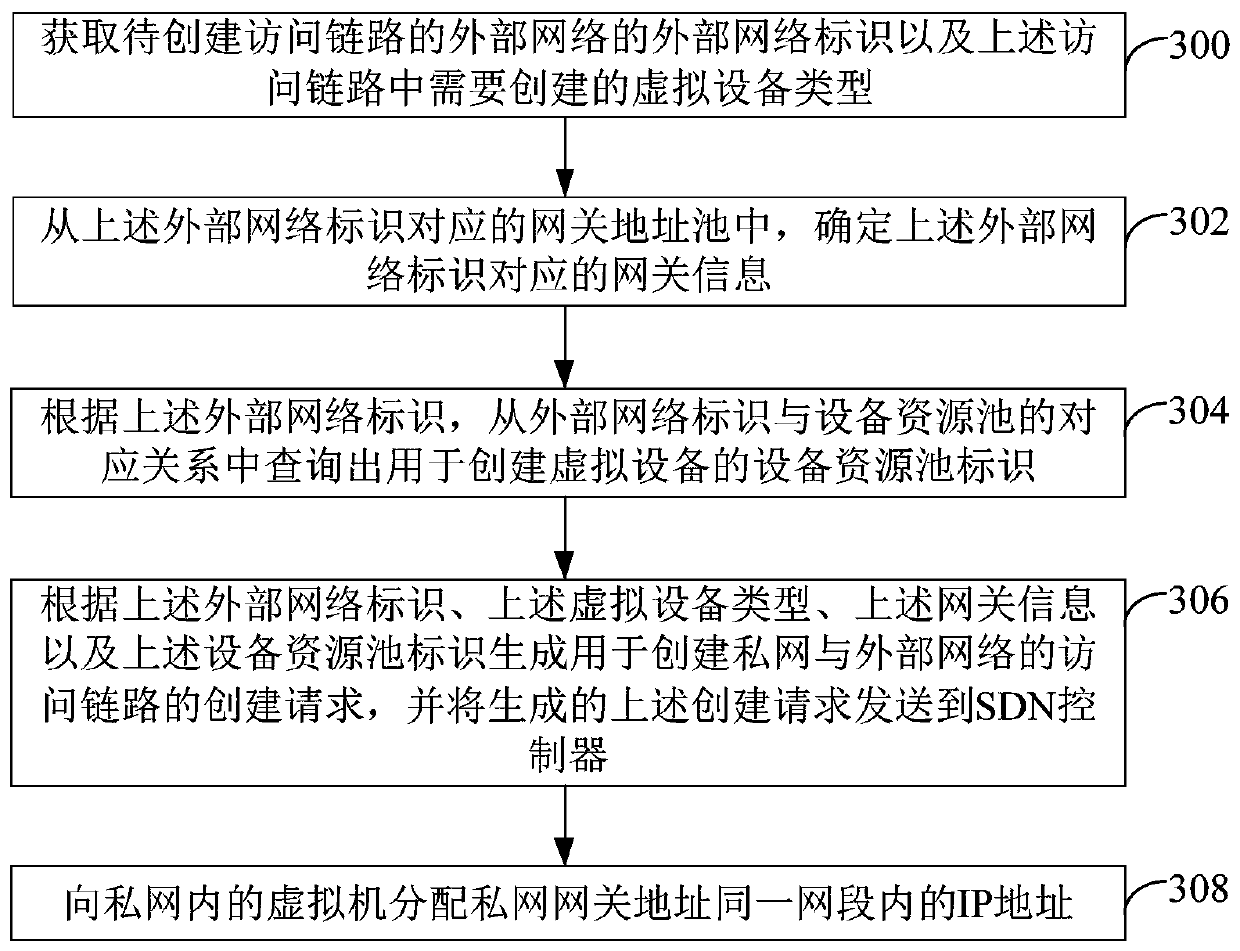

Network processing method, cloud platform and SDN controller

ActiveCN108063761AImprove securityAchieve the purpose of isolationTransmissionResource poolTraffic capacity

The invention provides a network processing method, a cloud platform and an SDN controller. A forwarding device determined according to an external network identifier in a device resource pool is configured according to gateway information and an interface address determined based on the external network identifier, an access link between a private network and an external network corresponding tothe external network identifier is created, corresponding access links are created for all external networks, so that traffic generated in access of the external networks by a private network user canbe sent to external networks through corresponding access links, traffic is isolated when the private network user accesses different external networks, and the private network user can access the external network more safely.

Owner:NEW H3C CLOUD TECH CO LTD

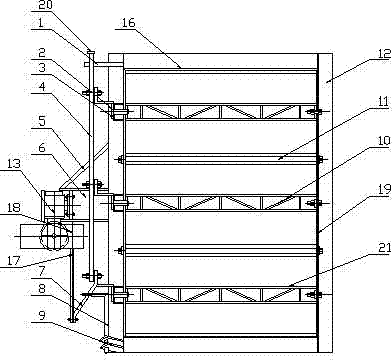

Air door device provided with turning plate for power station and blocking method

InactiveCN104329683AAchieve the purpose of isolationSimple structureDamper arrangementChimneysRatchetPower station

The invention discloses an air door device provided with a turning plate for a power station and a blocking method. The conventional air door does not have the function of a shutter or a turning plate door, and a sealing device is not provided for blocking media, thereby leading to environmental pollution, inconvenience in operation and unreasonable structure. The air door device provided with the turning plate for the power station is characterized in that a turning plate door (10) is connected with a door frame (12); the door frame is connected with a bearing seat (3); the bearing seat is connected with a ratchet shaft (2); the ratchet shaft is connected with a connecting rod shaft connecting plate (15); the connecting rod shaft connecting plate is connected with a connecting rod shaft (4); the connecting rod shaft connecting plate is connected with a hinge shaft (8); the hinge shaft is connected with a hinge shaft mounting plate (9); the hinge shaft mounting plate is connected with the door frame; the connecting rod shaft connecting plate is connected with a cylinder piston (17); the cylinder piston is connected with an air pump (18); the air pump is connected with a motor (13); the door frame is connected with a group of clapboards (11). The air door device is applied to a dust-removing system of flue gas and a partition of cold and hot air.

Owner:HEILONGJIANG HONGYU POWER STATION EQUIP

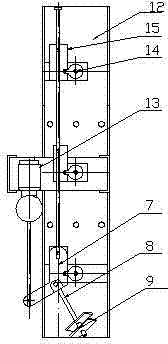

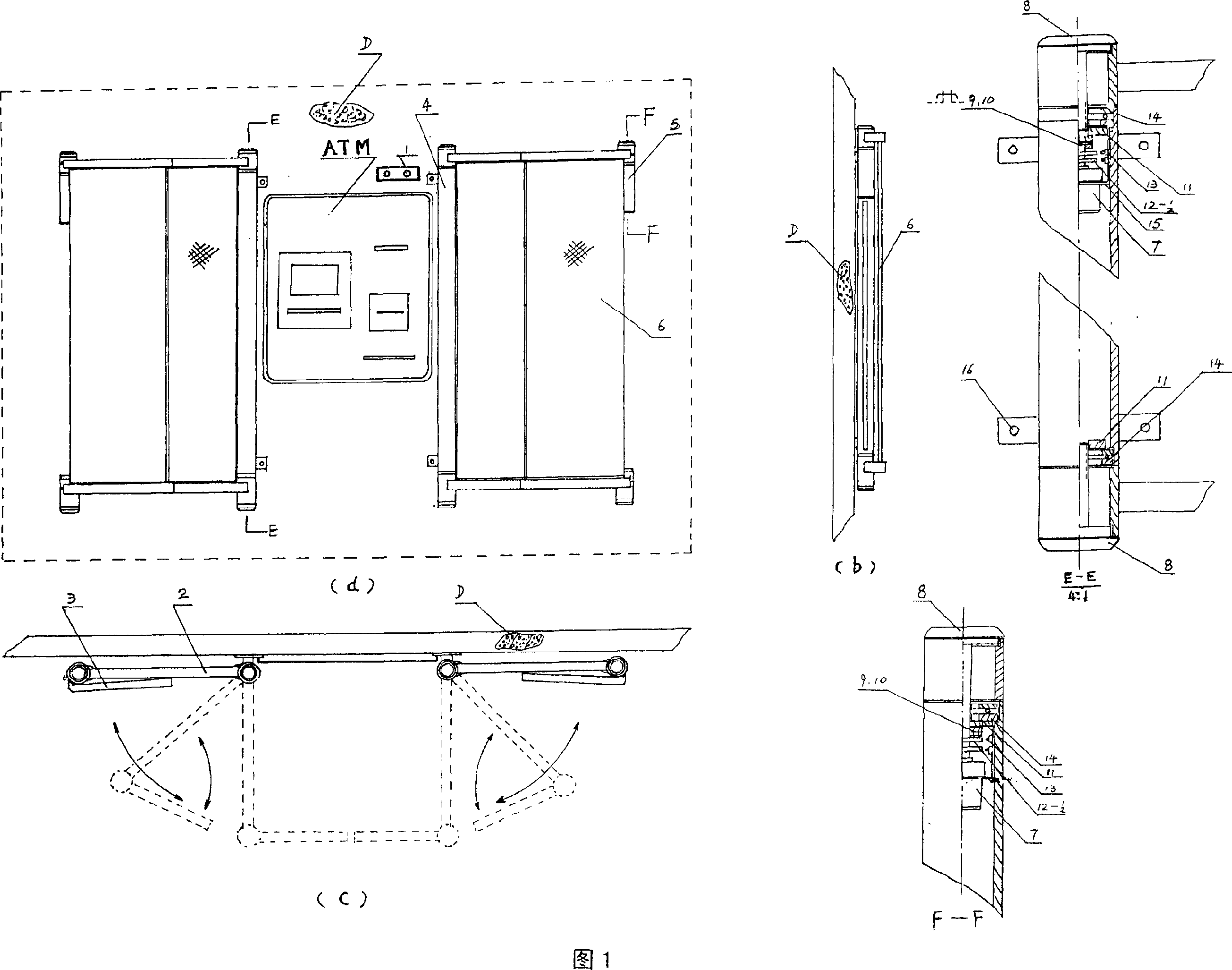

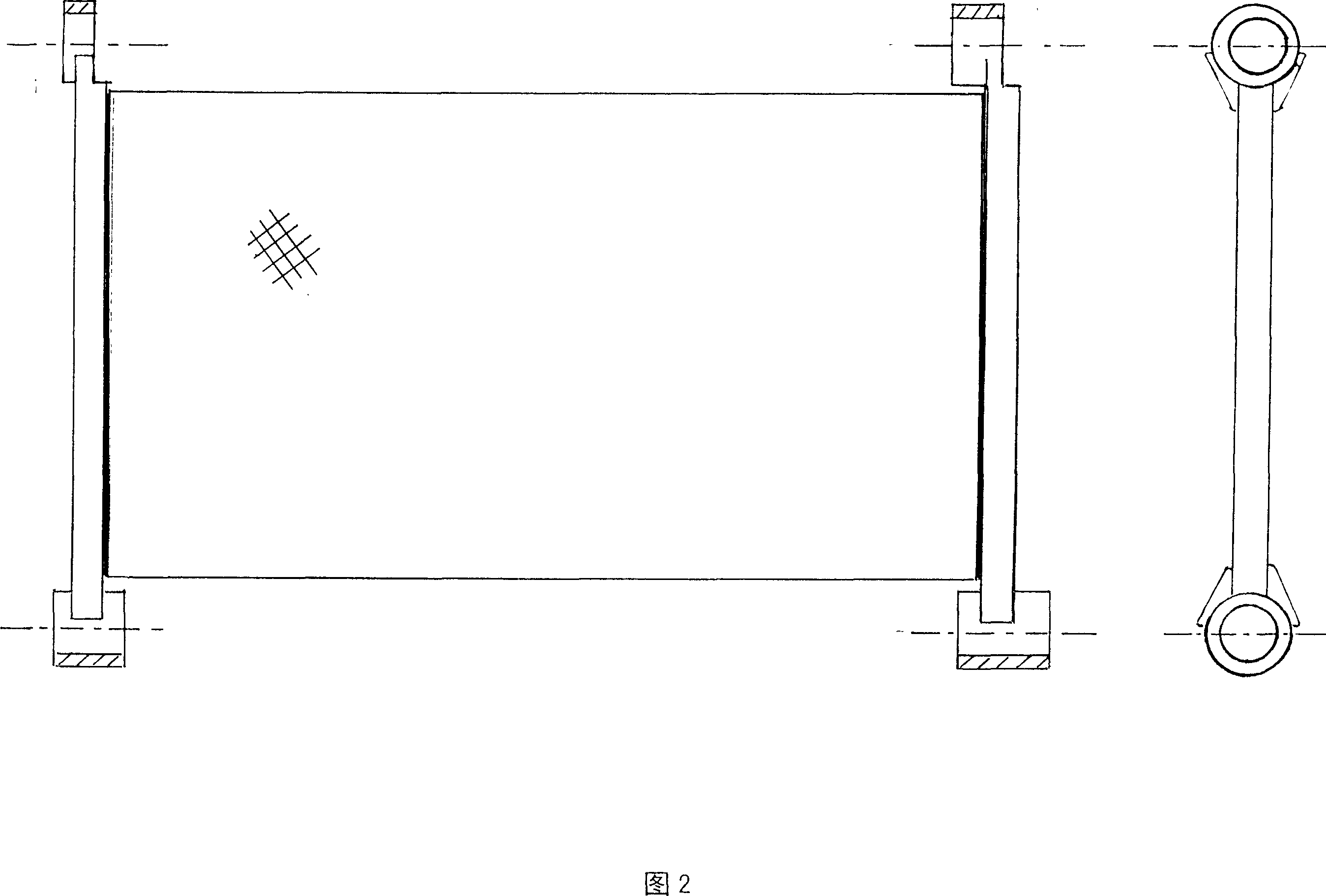

Electric near-wall folding protection gate barrier for bank ATM

InactiveCN101144363AAchieve the purpose of isolationDoes not affect the traffic functionBurglary protectionBank protection devicePasswordElectrical and Electronics engineering

The invention relates to an electrical wall pasting folding type guard door fence of a bank ATM Automatic Teller Machine, and is applied to the financial field, the invention is a guard door fence used to separate a payee and an outsider during the process of transacting the service when the ATM Automatic Teller Machine in a bank industry is used by being arranged at the outside, to prevent the unsafe hidden troubles caused by the password steal, the bank card fraud and steal, the cash steal and the disobey of the queuing sequence, to arranged the safety guard device for reducing the mental repression of the payee.

Owner:邵国忠

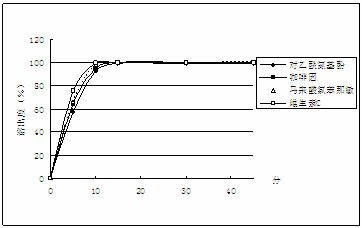

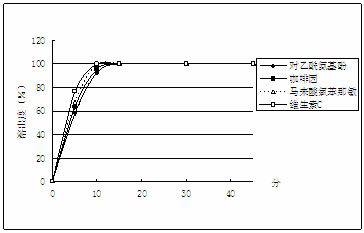

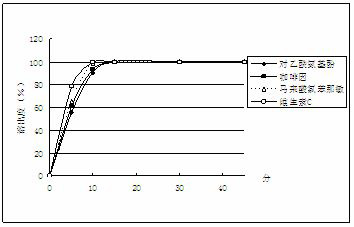

Acetaminophen, caffeine, chlorphenamine maleate, and vitamin C preparation and preparation method thereof

The invention discloses an acetaminophen, caffeine, chlorphenamine maleate, vitamin C preparation and a preparation method thereof, wherein the preparation is double-layer tablets which are respectively an acetaminophen granular layer embedded by beta-cyclodextrin, and a caffeine, chlorphenamine maleate and vitamin C granular layer, which are moulded by a tablet press. The preparation uses the beta-cyclodextrin to embed the acetaminophen so as to remarkably improve the stability and dissolution rate of the acetaminophen and reduce the stimulation and toxic side effects of medicaments; the beta-cyclodextrin can further reduce the offensive odour of the medicaments; moreover, the invention adopts the synergistic effect of the acetaminophen and the vitamin C so as to shorten the treatment course for curing the cold and make the cold be not easy to relapse; and the double-layer tablet structure achieves the purposes of isolating the acetaminophen and the caffeine, the chlorphenamine maleate and the vitamin C and solves the problems of metamorphic degradation, poor stability, short period of efficacy and the like caused by the interaction of the medicaments. The preparation is not easy to split, and is excellent in quality. The method is used for preparing the acetaminophen caffeine chlorphenamine maleate vitamin C double-layer tablet, and the preparation is mainly used for treating disease such as cold.

Owner:石药集团中诺药业(石家庄)有限公司

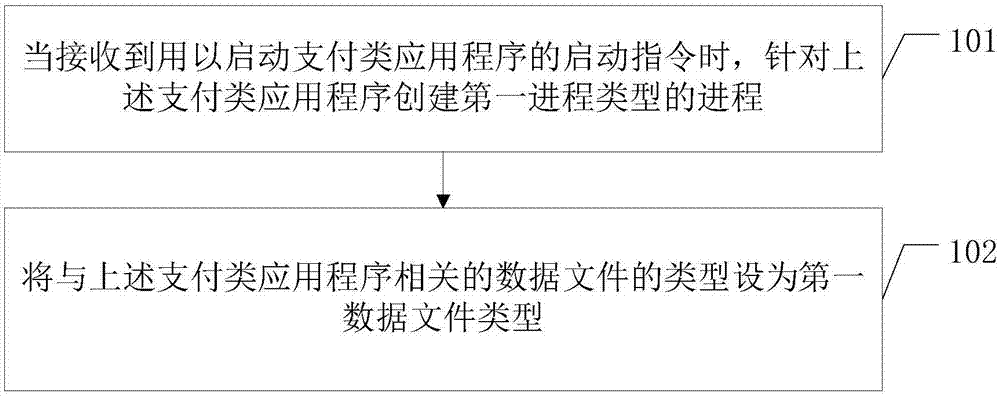

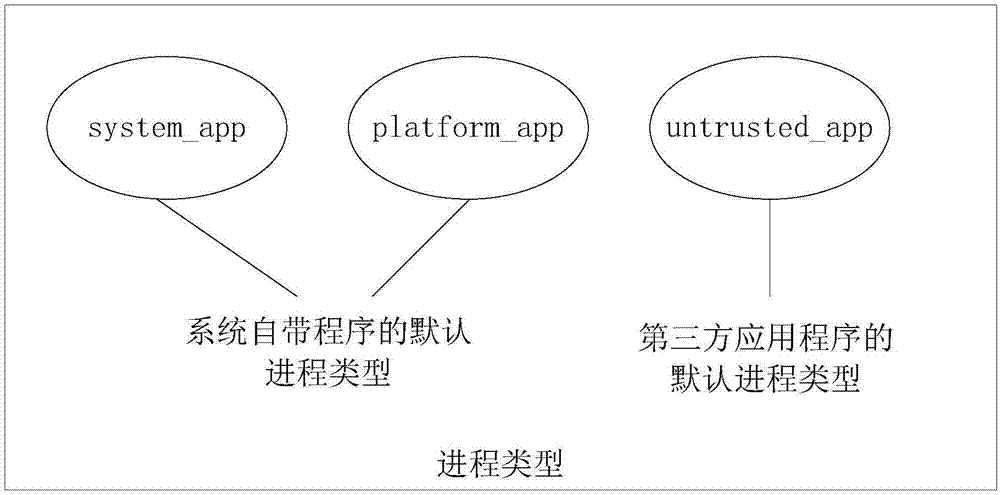

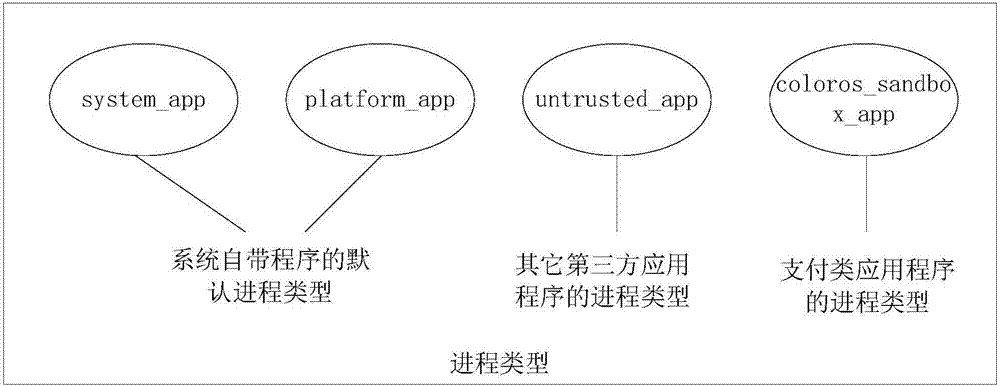

Payment application management method and apparatus, and mobile terminal

InactiveCN107315947AImprove securityAchieve the purpose of isolationComputer security arrangementsPayment protocolsData fileApplication software

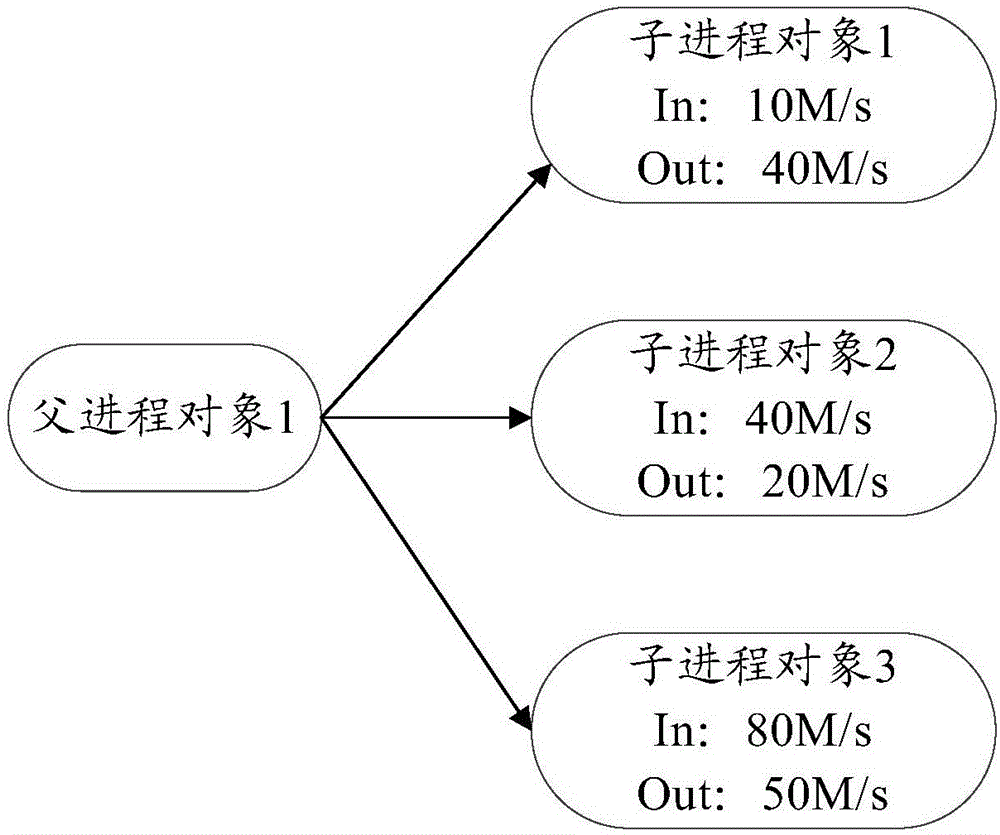

The invention discloses a payment application management method and apparatus, a mobile terminal and a computer readable storage medium. The payment application management method comprises the steps of creating a process of a first process type for a payment application when a starting instruction used for starting the payment application is received; and setting the type of a data file related to the payment application as a first data file type, wherein the first process type is different from a default process type of the application, the first data file type is different from a default data file type of the application, and the process of the first process type and the data file of the first data file type are prohibited from being accessed by processes of other process types. According to the technical scheme provided by the method, the security of mobile payment can be effectively improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

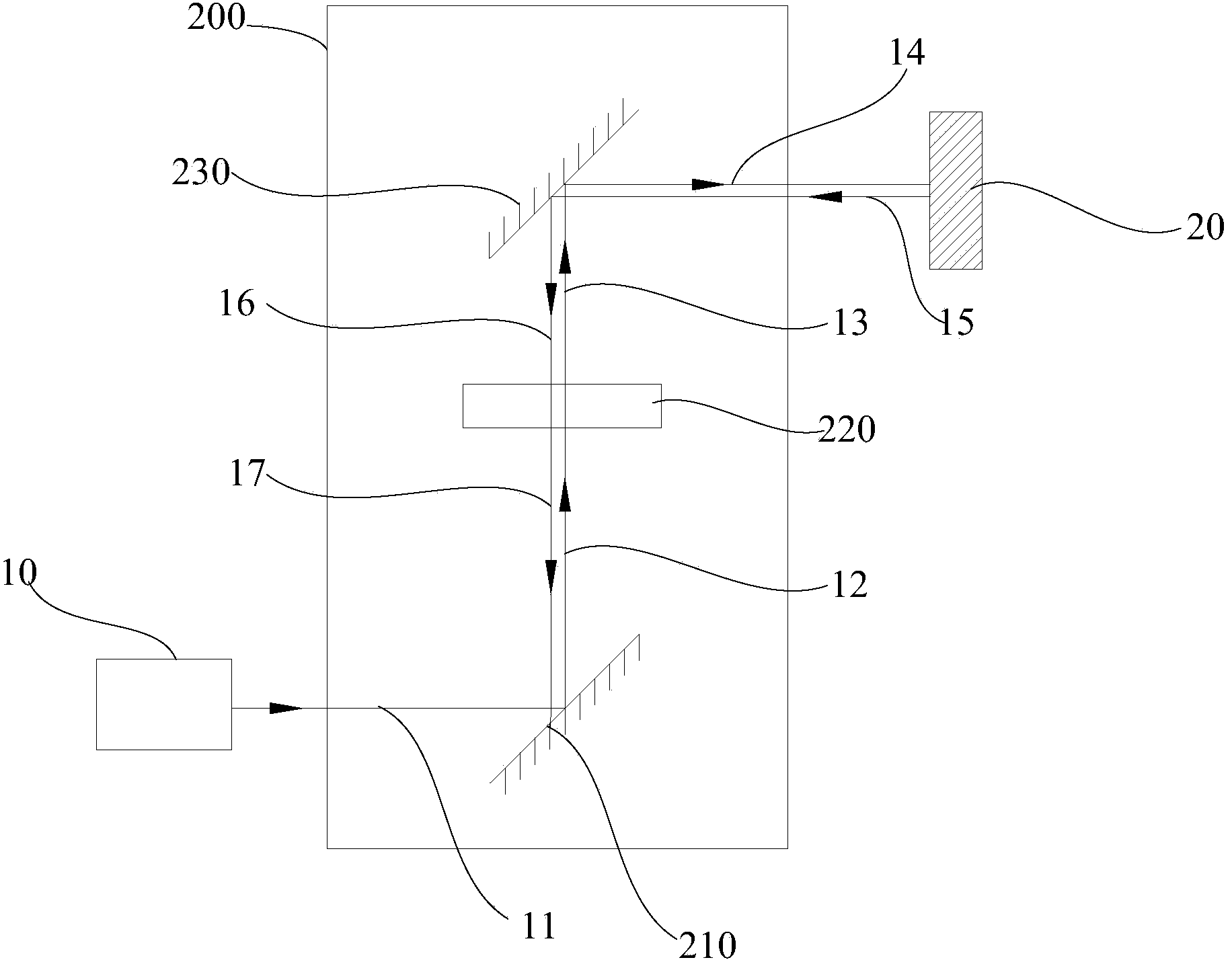

Optical isolation system and optical isolator

ActiveCN103592775AAvoid isolationAchieve the purpose of isolationMountingsOptical isolatorOptoelectronics

An optical isolation system used for isolating reflection lasers of a laser comprises a film absorption reflector and a 90-degree phase delay mirror, wherein the linearly polarized light is reflected at a 45-degree angle, the included angle between the polarized direction of the linearly polarized light and the reference surface is 45 degrees, and S polarized light is emitted out; the 90-degree phase delay mirror and the film absorption reflector are oppositely arranged in parallel, the 90-degree phase delay mirror can convert the S polarized light into circularly polarized light emitted out at a 45-degree reflection angle, and the circularly polarized light is used for processing a workpiece. An optical isolator converts the linearly polarized light into the circularly polarized light through the film absorption reflector and the 90-degree phase delay mirror. The circularly polarized light reflected by the workpiece is converted into P polarized light and is absorbed by the film absorption reflector finally, and therefore the lasers are prevented from being reflected into the laser, and the isolation purpose is achieved. The invention further provides the optical isolator comprising the optical isolation system.

Owner:HANS LASER TECH IND GRP CO LTD

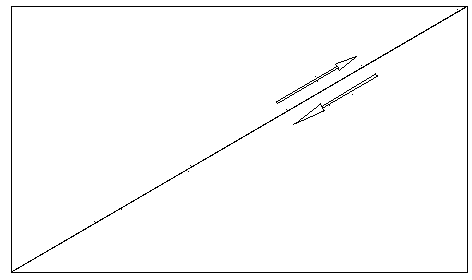

Storage method

InactiveCN109533451AAchieve the purpose of isolationAvoid scrappingPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringVacuum pumping

The invention relates to a storage method used for storing a PCB board. The method includes the following steps: storing the PCB board in a package; carrying out vacuum-pumping treatment on the package; filling the package with protective gas so as to isolate the PCB board from oxygen; and sealing the package so as to seal the protective gas in the package. Oxygen and water vapor in the package can be effectively removed by carrying out the vacuum-pumping treatment on the package. When the package is vacuum-pumped, the vacuum-pumped package is filled with the protective gas. Through the actionof the protective gas, the oxygen and water vapor can be completely discharged from the package, and the protective gas completely occupies the remaining accommodation space of the package. Finally,the package is sealed, and the protective gas is completely sealed in the package, thereby insolating the PCB board form oxygen and water vapor, and finally preventing the PCB board from being oxidized by oxygen and water vapor and scrapped.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

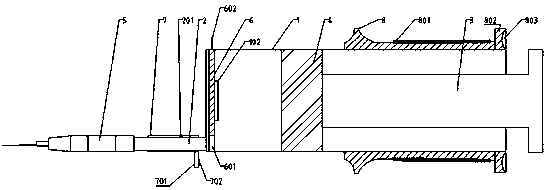

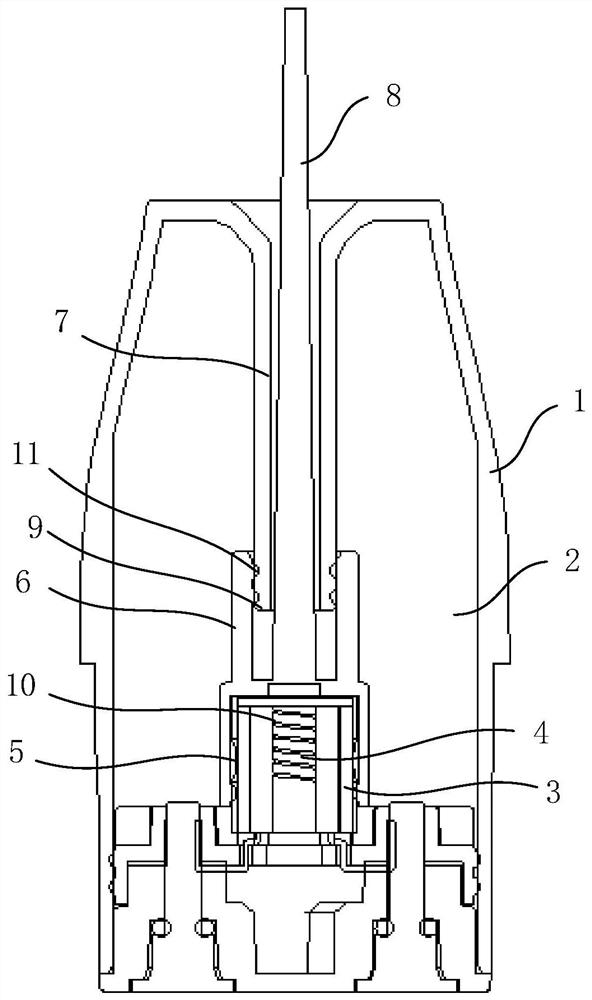

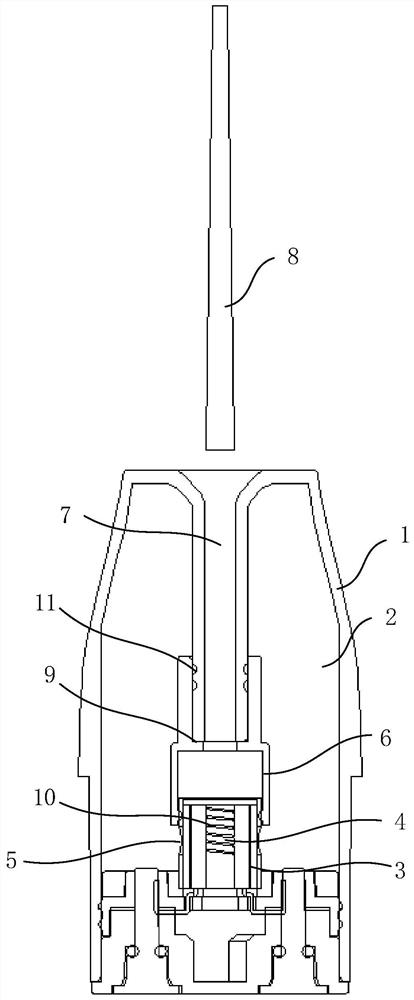

An arterial blood extractor capable of isolating air

InactiveCN109106378AAvoid the problem of swinging in the horizontal directionAchieve the purpose of isolationDiagnostic recording/measuringSensorsBlood gas testBlood arterial

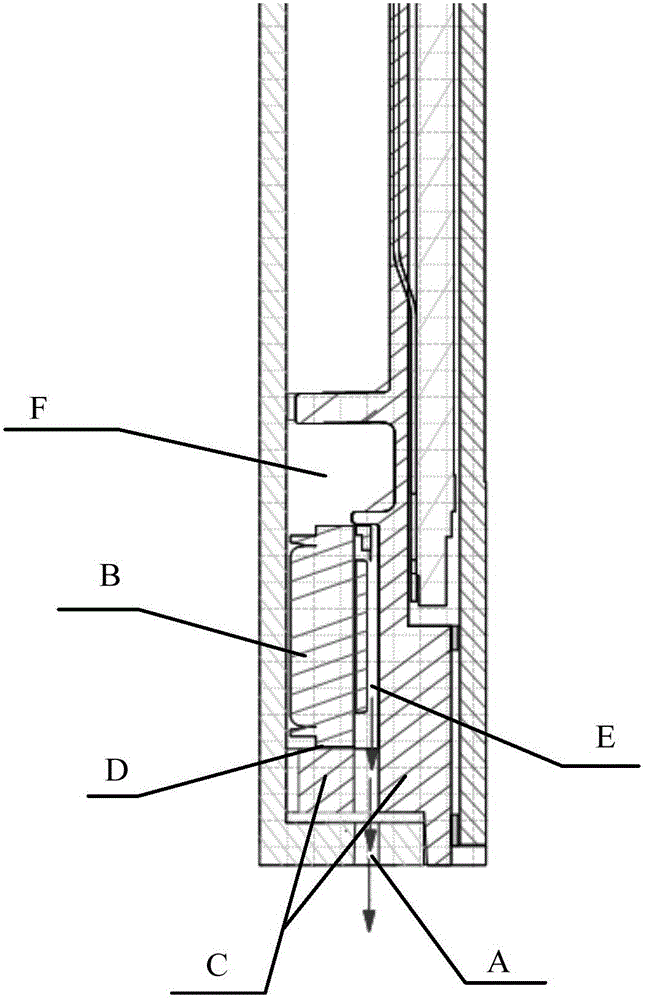

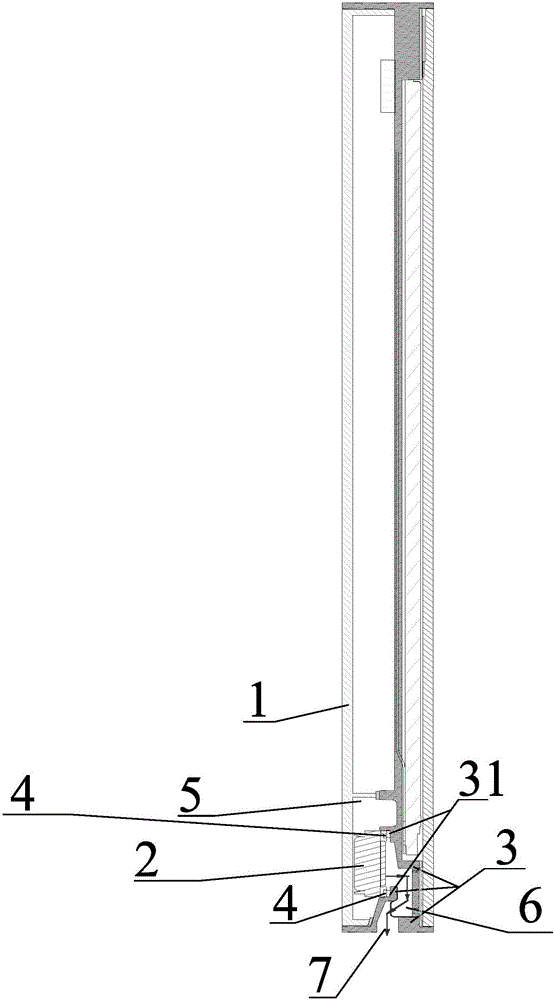

An arterial blood extractor capable of isolating air comprises a blood extractor, wherein the blood extractor is fixed on the front end of the piston push rod by a syringe, a connector, a piston pushrod, a piston, and a needle. The piston is fixed on the front end of the piston push rod, the piston and the piston push rod are loaded into the syringe from the rear end of the syringe, the piston issealingly matched with the syringe, the connector is fixed on the front end surface of the syringe; and the needle is mounted on the connector; the front end of the syringe is provided with a partition plate, the partition plate and the syringe are sealingly matched, an eccentric hole is arranged on the partition plate, an arc-shaped groove is arranged on the peripheral surface of the syringe relative to the partition plate, a rotary knob extends outward on the peripheral surface of the partition plate, the rotary knob passes through the arc-shaped groove, a finite position plate is symmetrically arranged on the inner wall of the syringe, and the partition plate is restricted in the front end of the syringe by a position limiting plate. The through hole on the rotary separator is dislocated from the joint hole on the front end of the syringe by rotating the separator so as to quickly realize the purpose of isolating the blood gas specimen from the air. The operation is simple and theisolation effect is good and safe.

Owner:SHIYAN TAIHE HOSPITAL

Mobile terminal

ActiveCN105979041AAchieve the purpose of isolationEasy maintenanceTelephone set constructionsEngineering

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

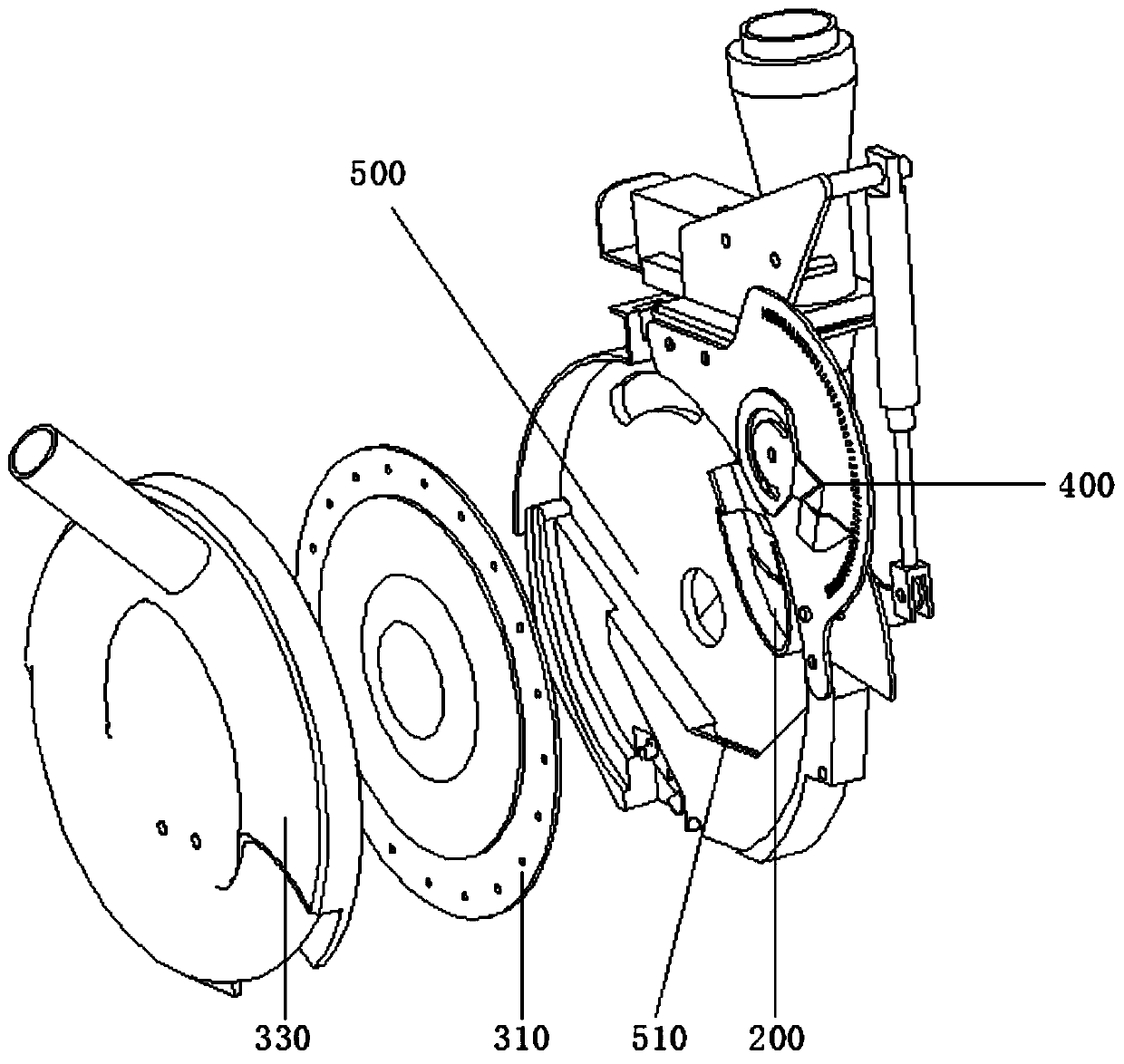

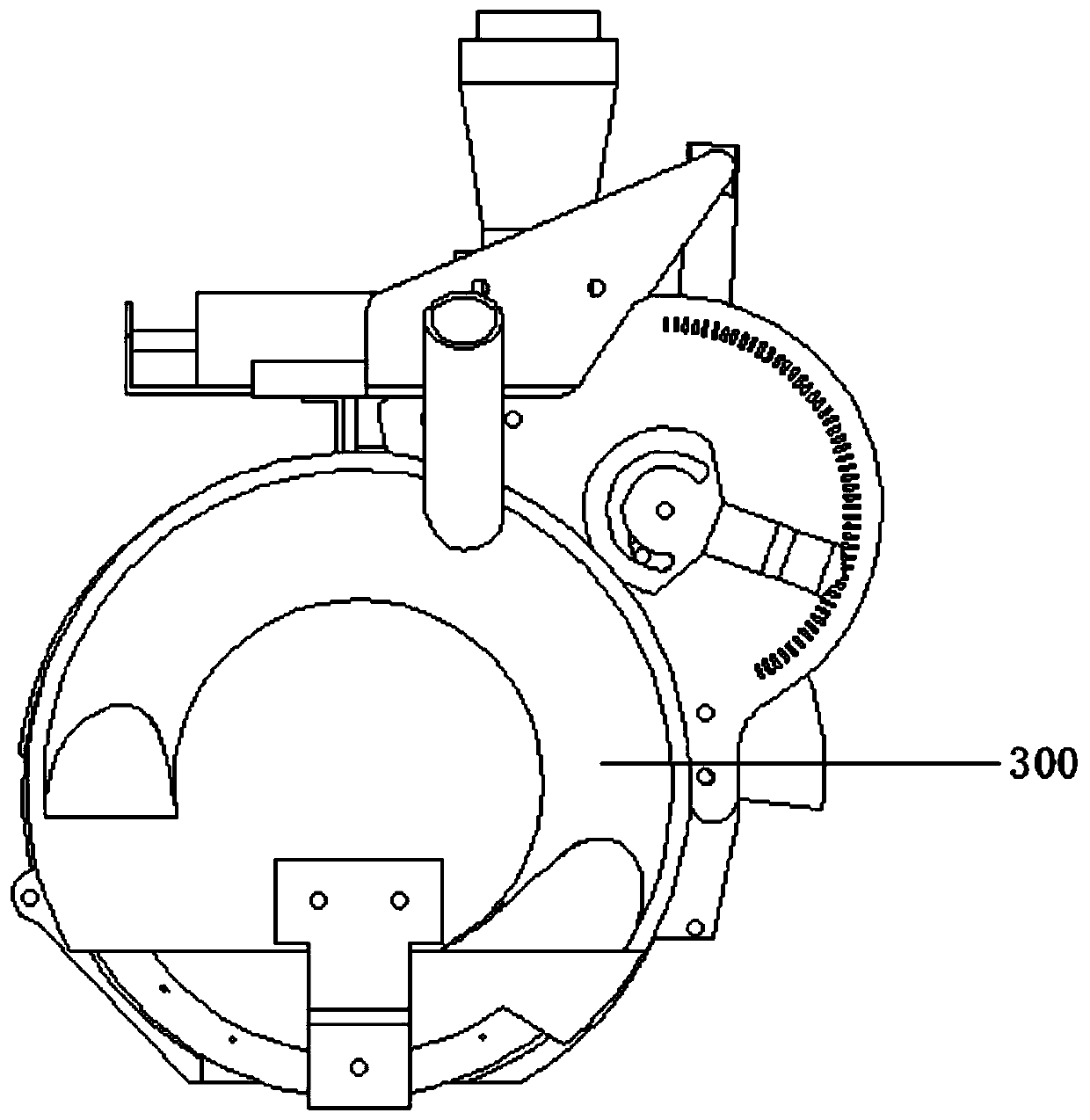

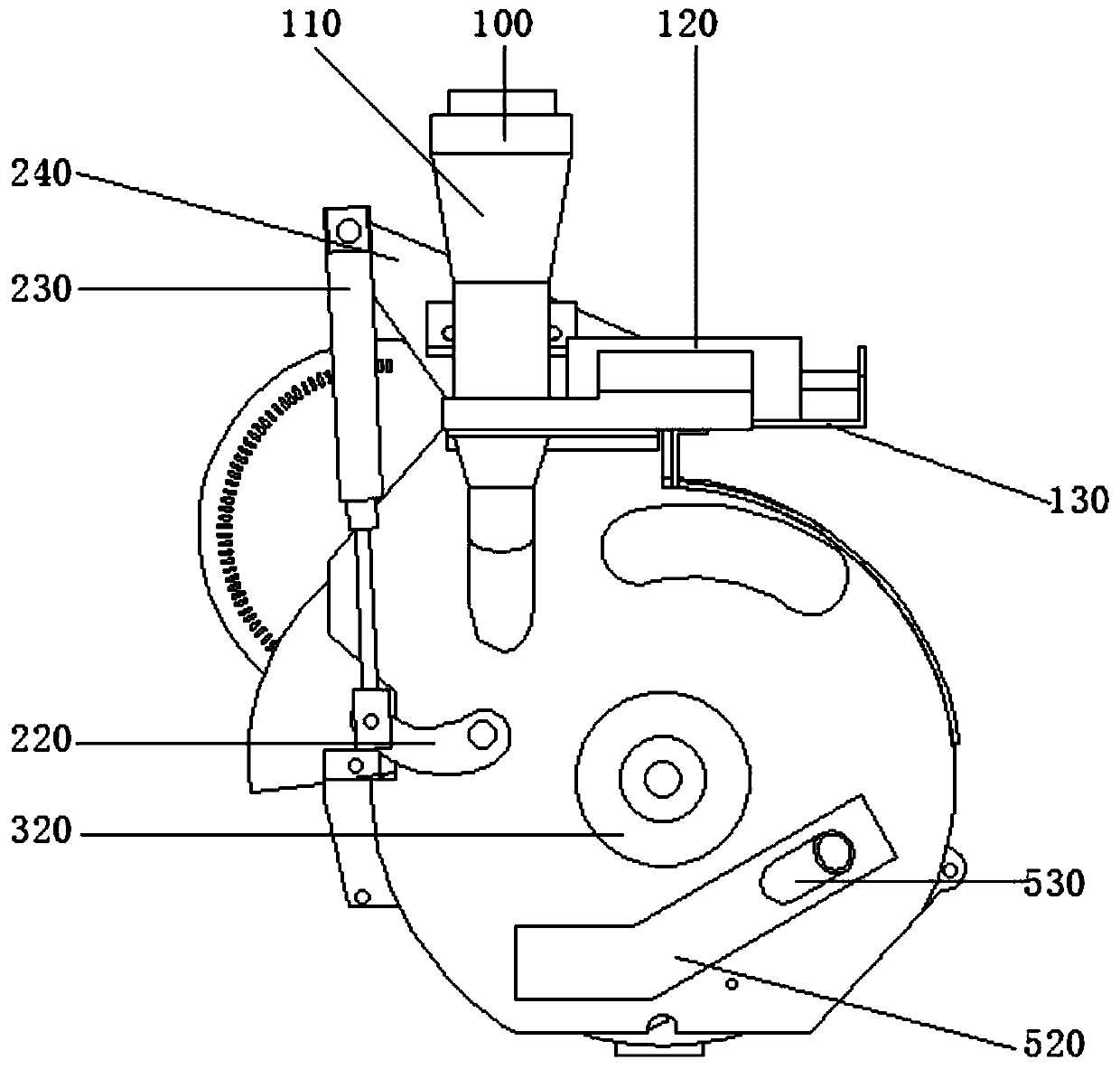

Small grain seed plot breeding precision sowing and arranging device and seed arranging method

PendingCN111406476AAchieve the purpose of isolationRealize continuous seeding and sowingSingle grain seedersAgricultural engineeringEngineering

The invention belongs to the technical field of agricultural machinery, and particularly relates to a small grain seed plot breeding precision sowing and arranging device and a seed arranging method.The device comprises a seed bin, a seed scoop, a seed arranging device, a seed scraping device and a seed cleaning device, wherein the seed bin, the seed scoop, the seed arranging device and the seedscraping device are all arranged on the seed cleaning device. The seed bin comprises a seed storage pipe, a bin gate cylinder and a bin door plate; the seed scoop comprises a scoop chamber, a rotatingplate, a seed scoop cylinder and a fixed plate; the seed arranging device comprises a seed disc, a driving wheel and a negative pressure disc; the seed scraping device comprises a scraping plate, anadjusting pointer and an adjusting disc; and the seed cleaning device is provided with an inoculation hole, a seed cleaning cavity and a seed cleaning pipe. The invention also provides the seed arranging method of the small grain seed plot breeding precision sowing and arranging device. The problems of low precision sowing degree, serious seed mixing, complex seed cleaning, low automation degree,complex operation, high fault rate and the like in an existing sowing technology are solved.

Owner:青岛普兰泰克机械科技有限公司 +1

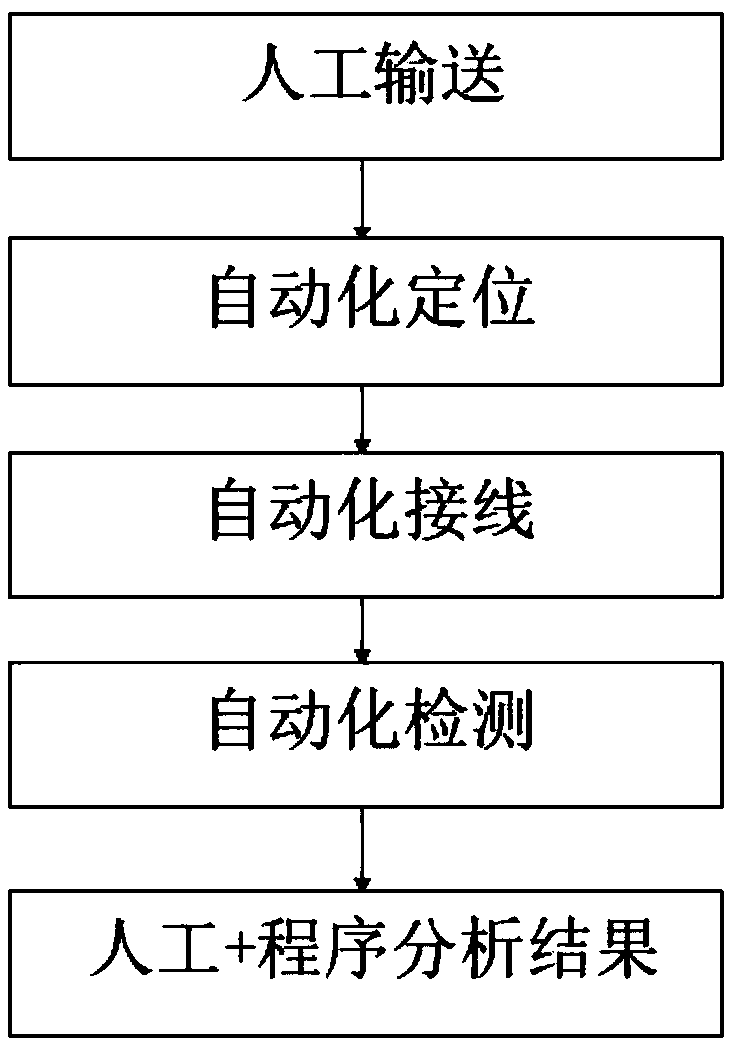

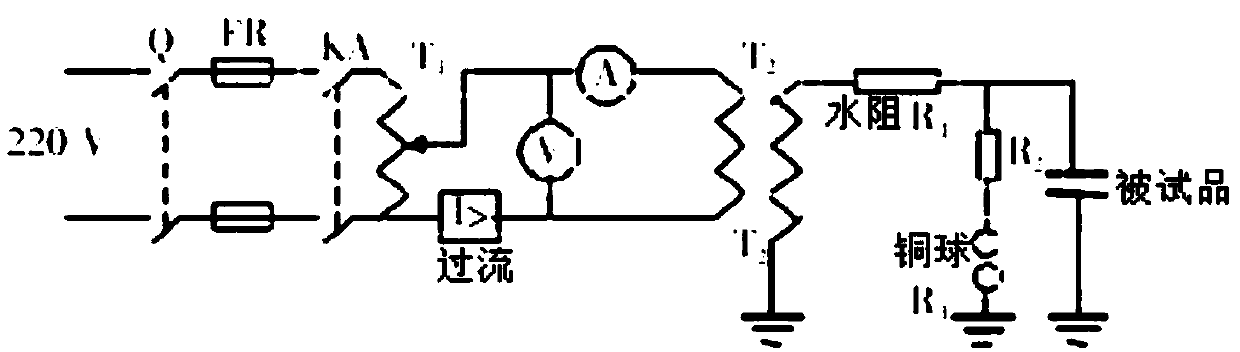

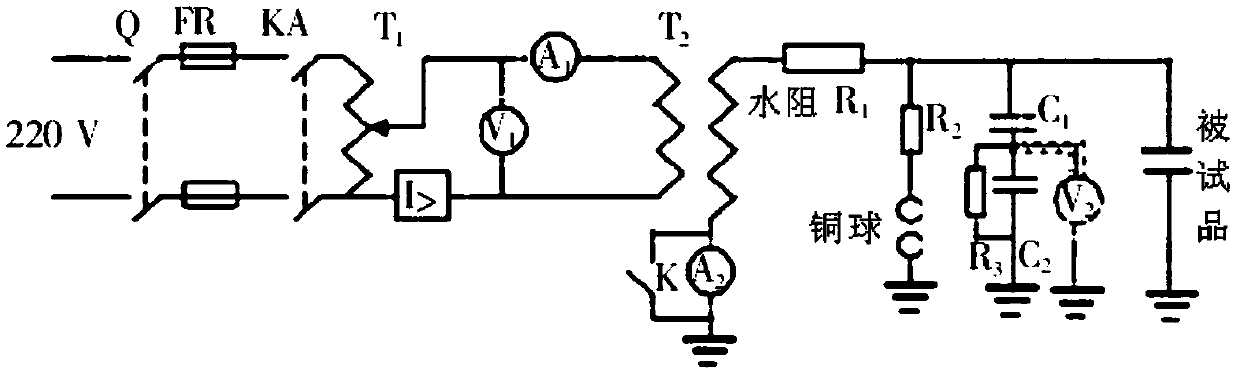

Semi-automatic detection method for withstand voltage test of high-voltage transformer

InactiveCN109581156AImprove accuracyImprove consistencyTesting dielectric strengthComputer control systemSemi automatic

The invention relates to a semi-automatic detection method for a withstand voltage test of a high-voltage transformer. The method comprises the following steps: (1) the high-voltage transformer uses apallet as a carrier, an operator puts the transformer and the pallet onto a conveyor line by a forklift or other lifting tools; (2) a positioning module performs a precise positioning after reachingthe specified position, a positioning system is composed of a chamfered pin shaft and has a ground connection function, and a secondary automatic wiring module and a primary wiring module perform wiring after precise positioning, wherein a PLC control system issues commands to automatically perform the above operations; (3) after the wiring, a verification system performs verification analysis oneach detection item; (4) an upper computer control system determines whether the verification analysis result is qualified or not, and the results of some verification items need manual determination.The semi-automatic detection method for the withstand voltage test of the high voltage transformer improves the verification efficiency and improves the safety of high-pressure item detection.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

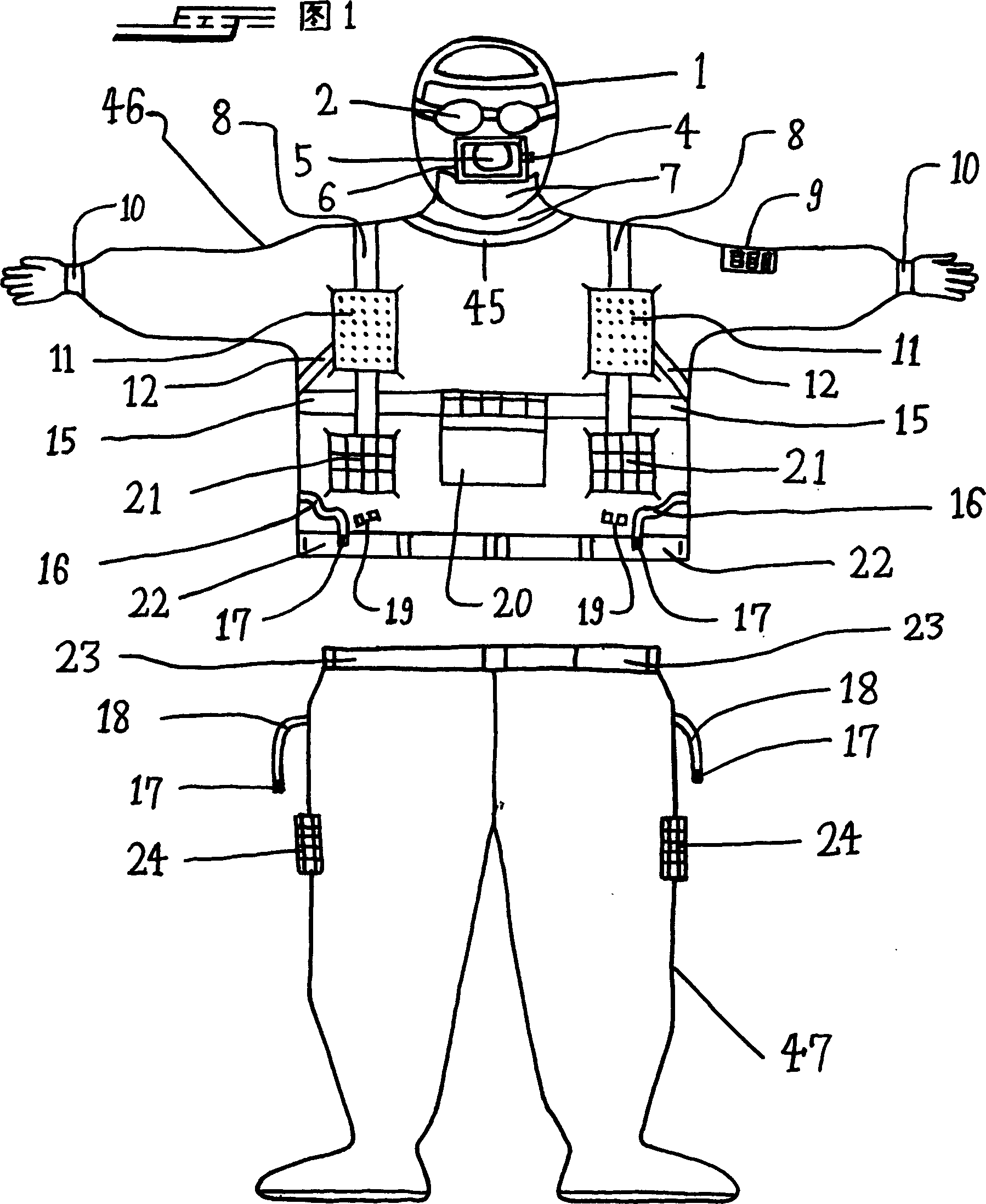

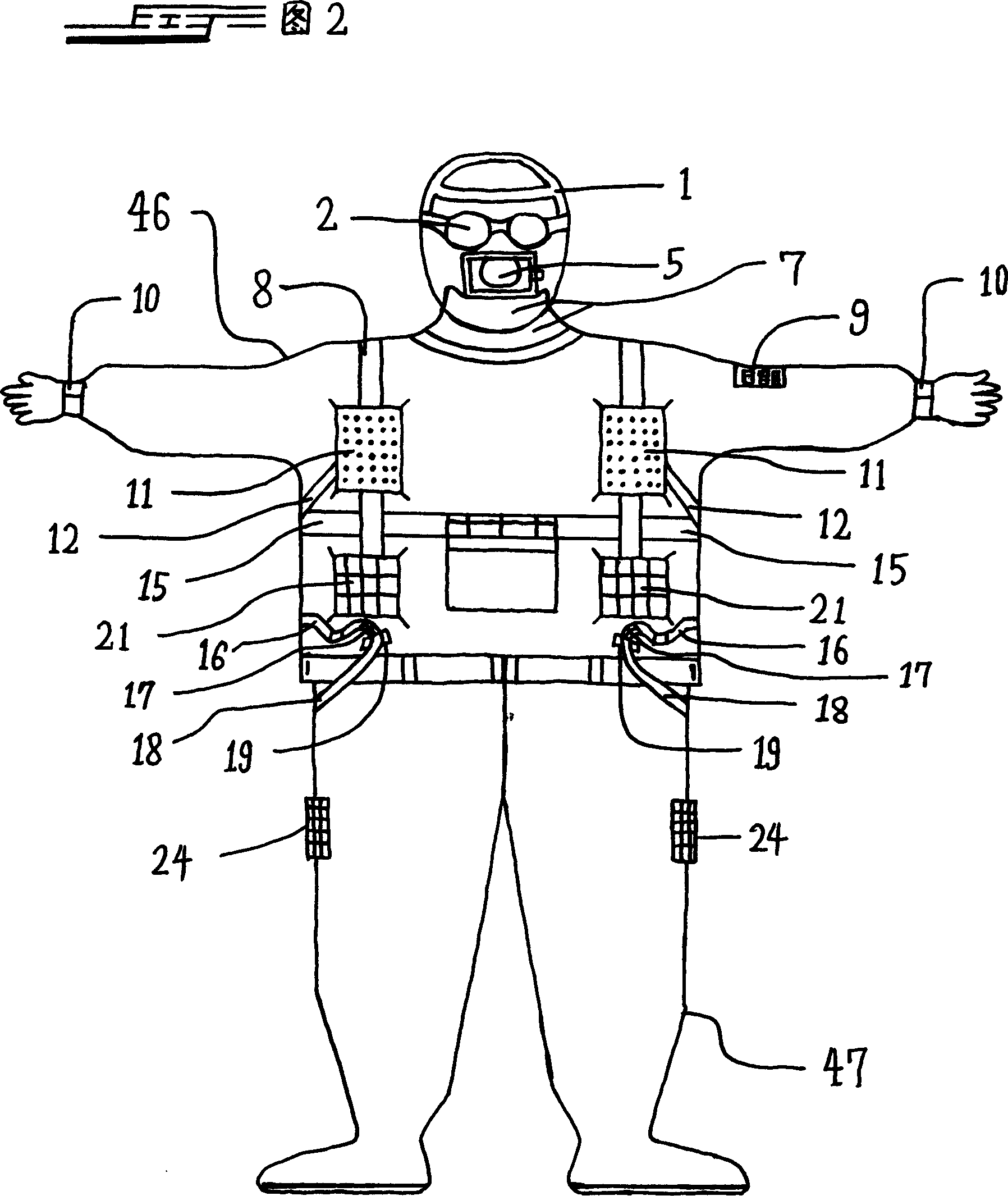

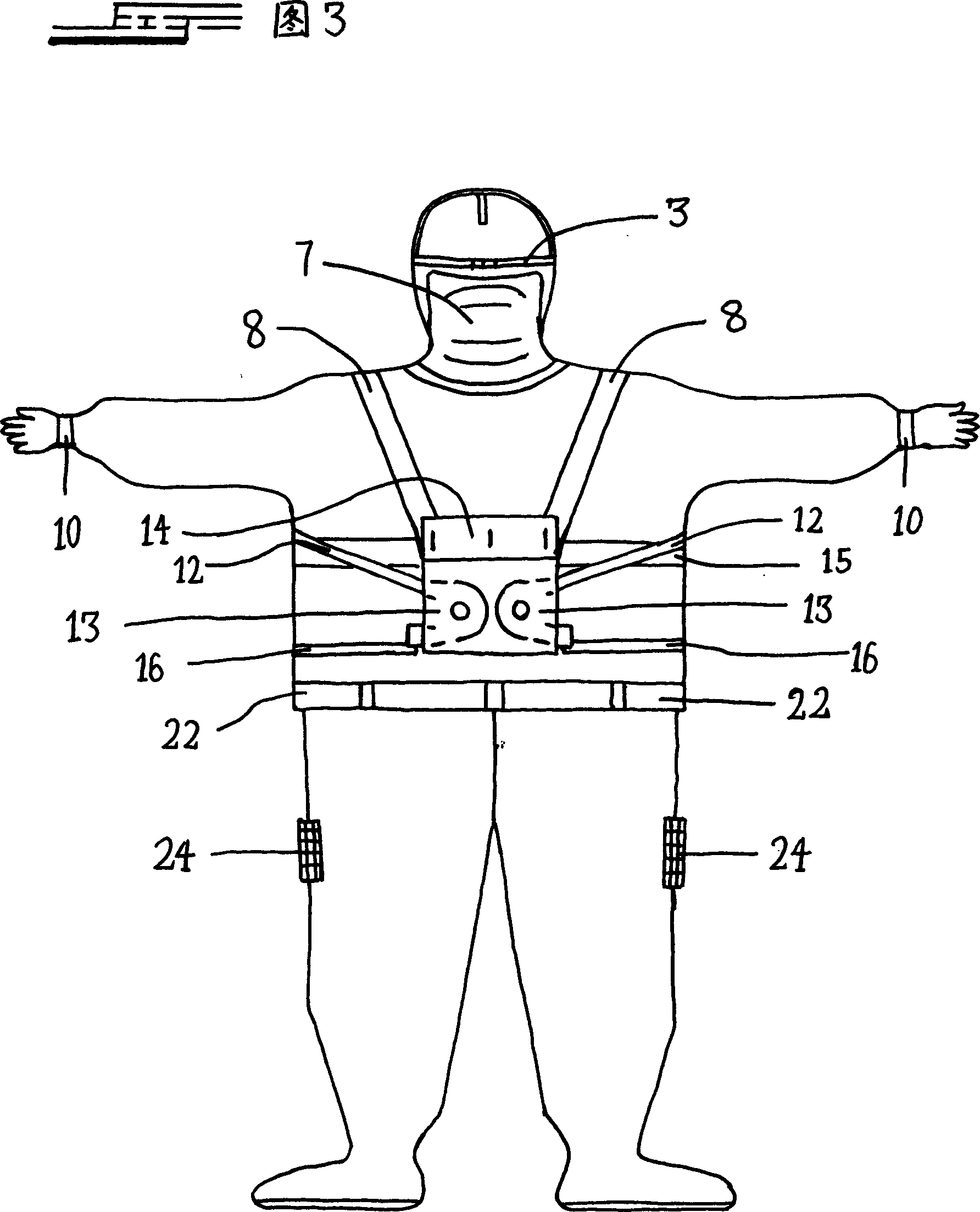

Virus protective clothing with electric breathing system

InactiveCN1552486AConversational convenienceConvenient cleaning workChemical protectionHeat protectionControl systemPower control system

A virus isolating clothing with electric respiratory system features that its electric respiratory system is composed of sealing system for clothing, folding system, double disinfecting filter system, air moistening system, air admission system, air exhaust system and power supply control system. Its advantages are high isolating effect and very comfortable.

Owner:郝利兵

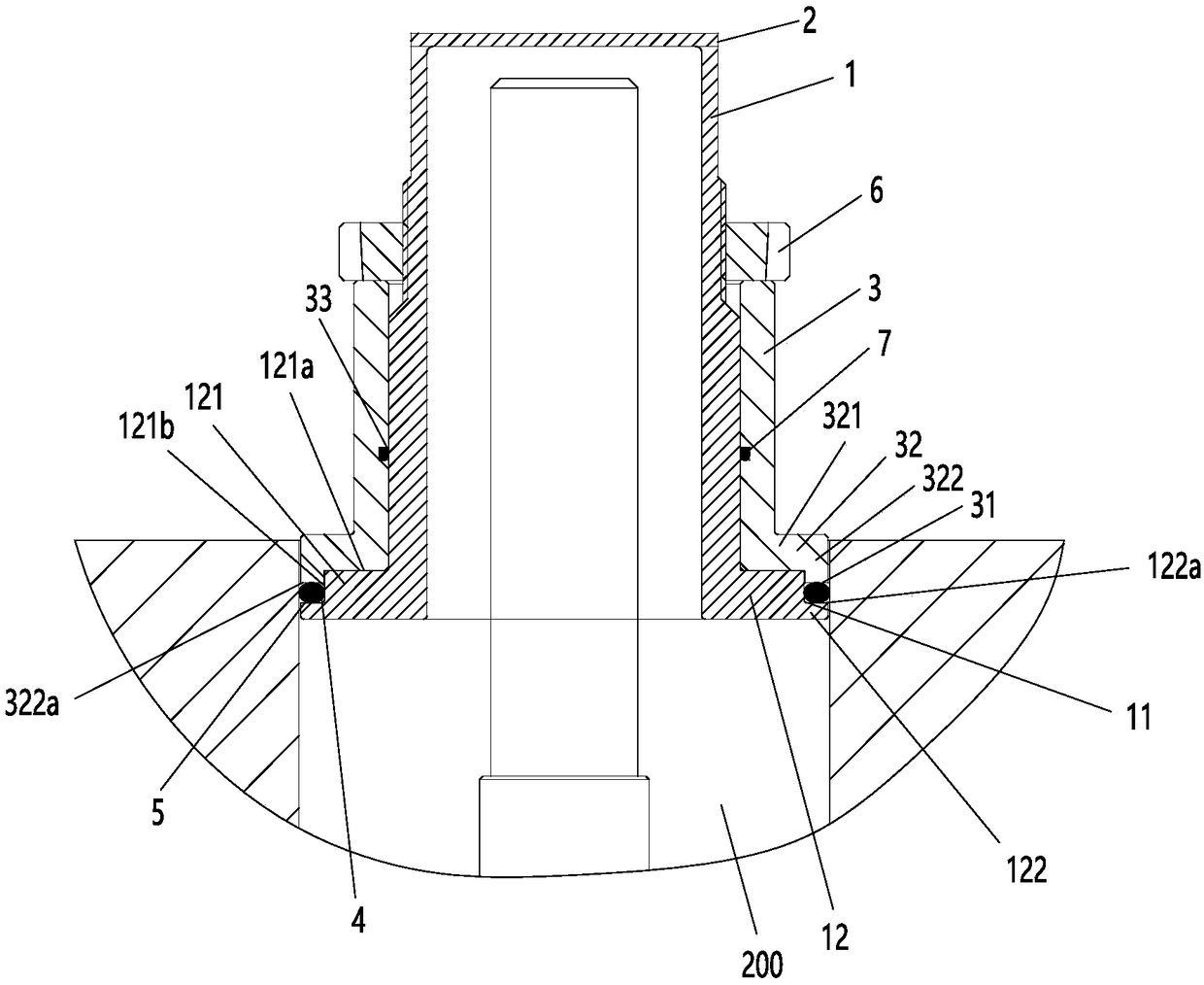

Sealing structure for repairing pebble-bed high-temperature reactor device

ActiveCN108899100ASimple structureRealize blockingNuclear energy generationContainmentEngineeringMechanical engineering

The invention relates to the technical field of sealing equipment for repairing reactor equipment and discloses a sealing structure for repairing a pebble-bed high-temperature reactor device. The sealing structure comprises a drum body, a sealing end plate, a pressing sleeve, a sealing part and a screwing and pressing part, wherein an opening is structured at the upper end of the drum body; the sealing end plate is arranged at the opening part of the drum body; the pressing sleeve is sheathed at the periphery of the drum body and can do up-down reciprocating sliding along the axial direction of the drum body, and a ring groove is commonly structured by the upper surface of the bottom end of the drum body and the lower surface of the bottom end of the pressing sleeve; the sealing part is arranged in the ring groove; the screwing and pressing part is sheathed at the periphery of the sleeve body and is positioned at the upper part of the pressing sleeve. By screwing of the screwing and pressing part, the screwing and pressing part can drive the pressing sleeve to do axial downward movement along the drum body and extrude the sealing part to be deformed so as to block the ring groove.The sealing structure disclosed by the invention has the advantage that isolation of internal and external pressure, atmosphere and dust of the pebble-bed high-temperature reactor device can be betterrealized.

Owner:TSINGHUA UNIV

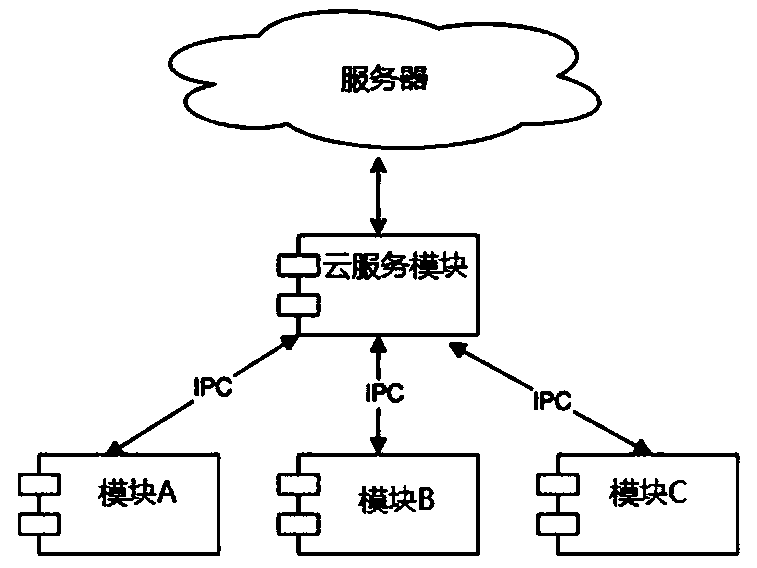

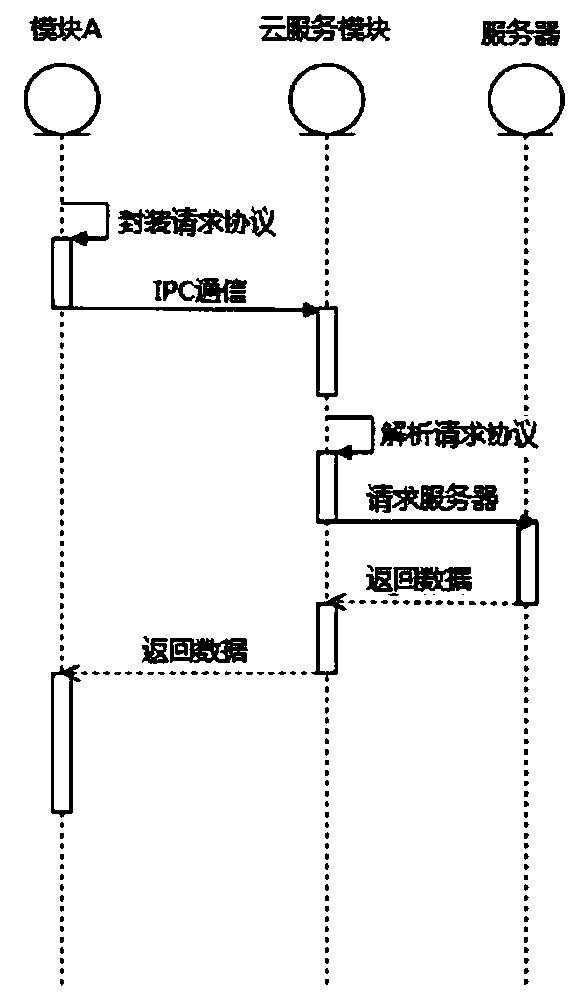

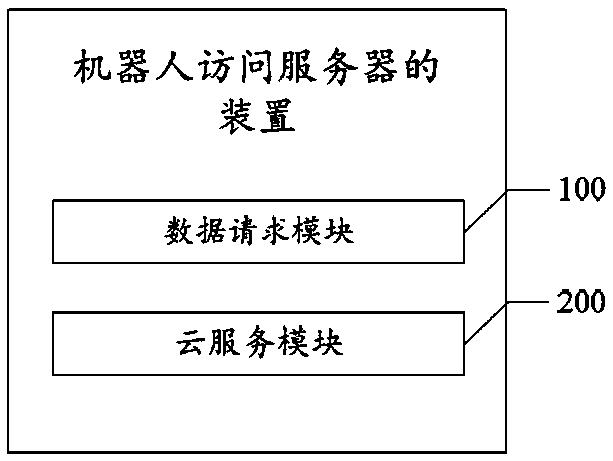

Method and device for robot to access server, and storage medium

InactiveCN111212097AImprove scalabilityAchieve the purpose of isolationTransmissionCommunication interfaceHuman–computer interaction

The invention discloses a method and device for a robot to access a server, and a storage medium, and the method comprises the steps: carrying out the packaging of request information through a data request module, and transmitting the packaged request information to a cloud service module in the robot through an IPC communication interface according to a user-defined communication protocol; enabling the cloud service module to receive and analyze the packaged request information through the IPC communication interface to obtain request information corresponding to an analyzed standard communication protocol, and sending the obtained request information of the standard communication protocol to a server; enabling the cloud service module to receive response information returned by the server according to the request information of the standard communication protocol, and sending the response information to the data request module through an IPC communication interface according to thecustom communication protocol. According to the invention, the purpose of isolating the module of the robot for accessing the server from the specific product form of the robot is achieved, and the maintenance cost is reduced.

Owner:JUXING TECH SHENZHEN CO LTD

Cartridge and electronic cigarette

The invention discloses a cartridge and an electronic cigarette. The cartridge comprises a tar cup, a tar storage cavity for storing tobacco tar, an atomizer, a smoke channel and a sealing sleeve, wherein the atomizer is arranged in the tar cup; an atomizing cavity and a tar inlet are formed in the atomizer; the smoke channel is located in the middle of the tar cup and used for making the outsidecommunicate with the atomizing cavity; an atomizing seat is sleeved with the sealing sleeve; and the tar inlet is covered with the sealing sleeve. In use, the sealing sleeve is driven to move in the direction away from the atomizing cavity, so that the tar inlet separately communicates with the tar storage cavity and the atomizing cavity. By means of the cartridge, the technical problem is solvedthat in the correlated technology, because no cartridge is employed, the contact time of the tobacco tar and the atomizing cavity is too long, and tobacco tar leakage is caused.

Owner:唯它(深圳)科技有限公司

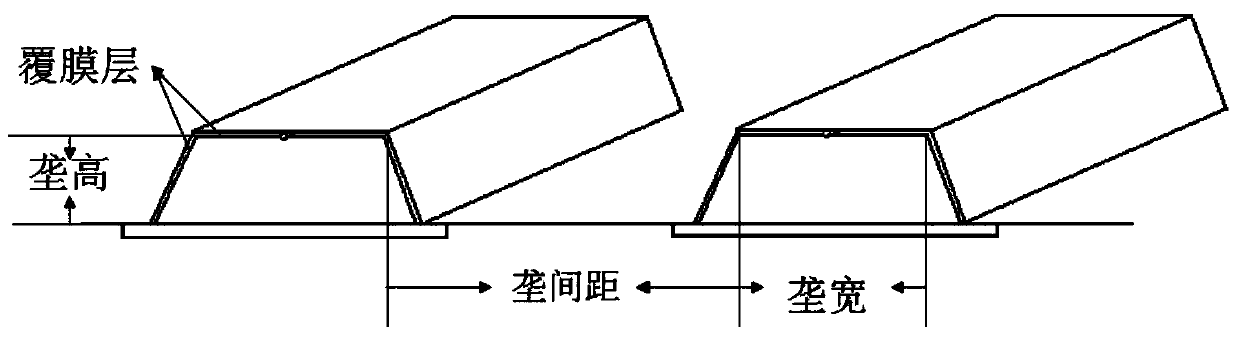

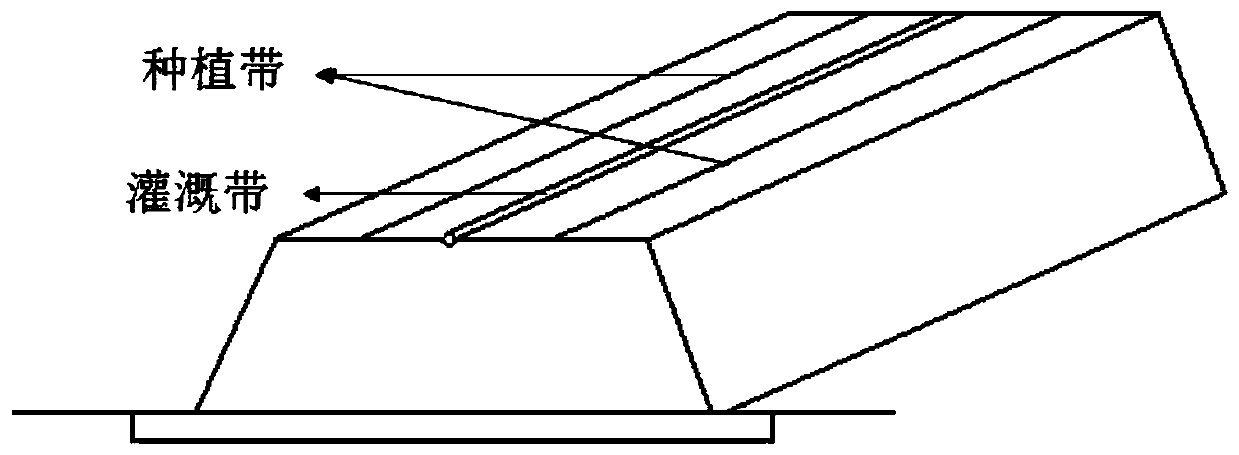

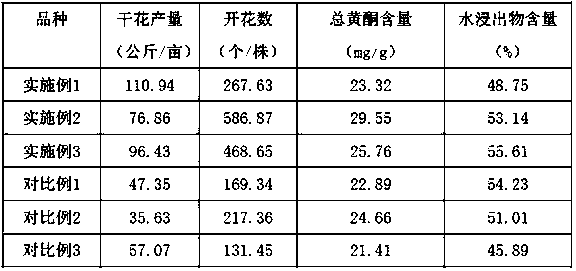

Method for planting chrysanthemum in saline-alkali soil of Yellow River Delta

InactiveCN111109037AExpand the scope of plantingIncrease profitFlowers cultivationPlant protective coveringsSoil scienceAlkali soil

The invention relates to a chrysanthemum planting method, in particular to a method for planting chrysanthemum in saline-alkali soil of the Yellow River Delta. According to the method for planting crops in the saline-alkali soil of the Yellow River Delta, a ridging planting mode is adopted, a film covering technology is used for preventing alkali and maintaining moisture at the same time, and thenan alkali absorption layer is used for achieving the purpose of isolating a planting area from an alkali layer. The alkali absorption layer allows water to seep to the ground underneath, but preventsunderground alkali or alkali at two sides to enter ridges; hardwood sawdust is used as the alkali absorption layer, can adsorb a large amount of salt downwardly infiltrating along with moisture in soil, and can prevent salt at the lower part of an alkali isolation layer from moving upward and entering a plant planting layer along with evaporation of moisture in drought seasons; and the hardwood sawdust is slowly rotted as time goes on, so the granular structure of the soil can be better improved, and organic matters in the soil are increased.

Owner:SHANDONG INST OF POMOLOGY

Network processing method, cloud platform and software-defined network sdn controller

ActiveCN108063761BImprove securityAchieve the purpose of isolationTransmissionResource poolPrivate network

This application provides a network processing method, cloud platform and SDN controller, through the gateway information and interface address determined by the external network identifier, configure the forwarding device in the device resource pool determined by the external network identifier, and create a private network The access link of the external network corresponds to the external network ID, so as to create corresponding access links for each external network, so that the traffic generated by private network users accessing each external network can pass through the access links corresponding to each external network respectively Sending to each external network achieves the purpose of traffic isolation when private network users access different external networks, and improves the security of private network users accessing external networks.

Owner:NEW H3C CLOUD TECH CO LTD

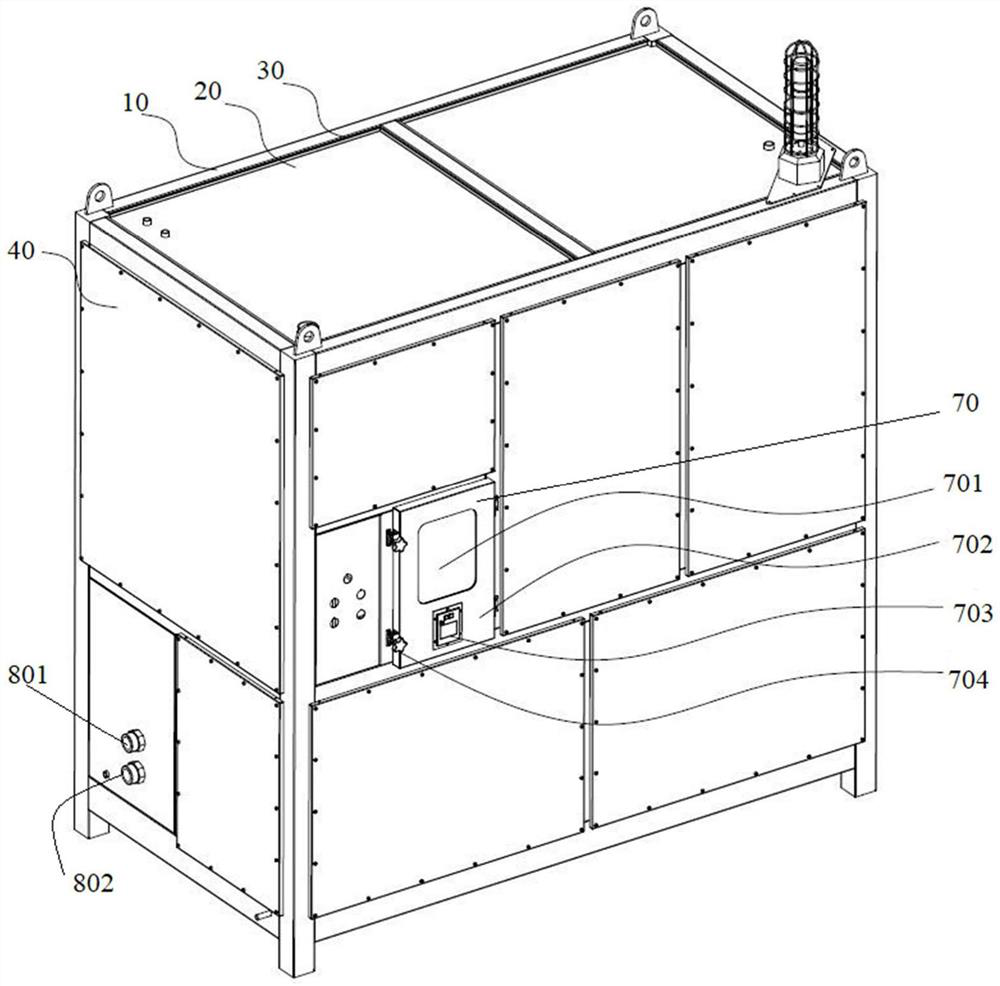

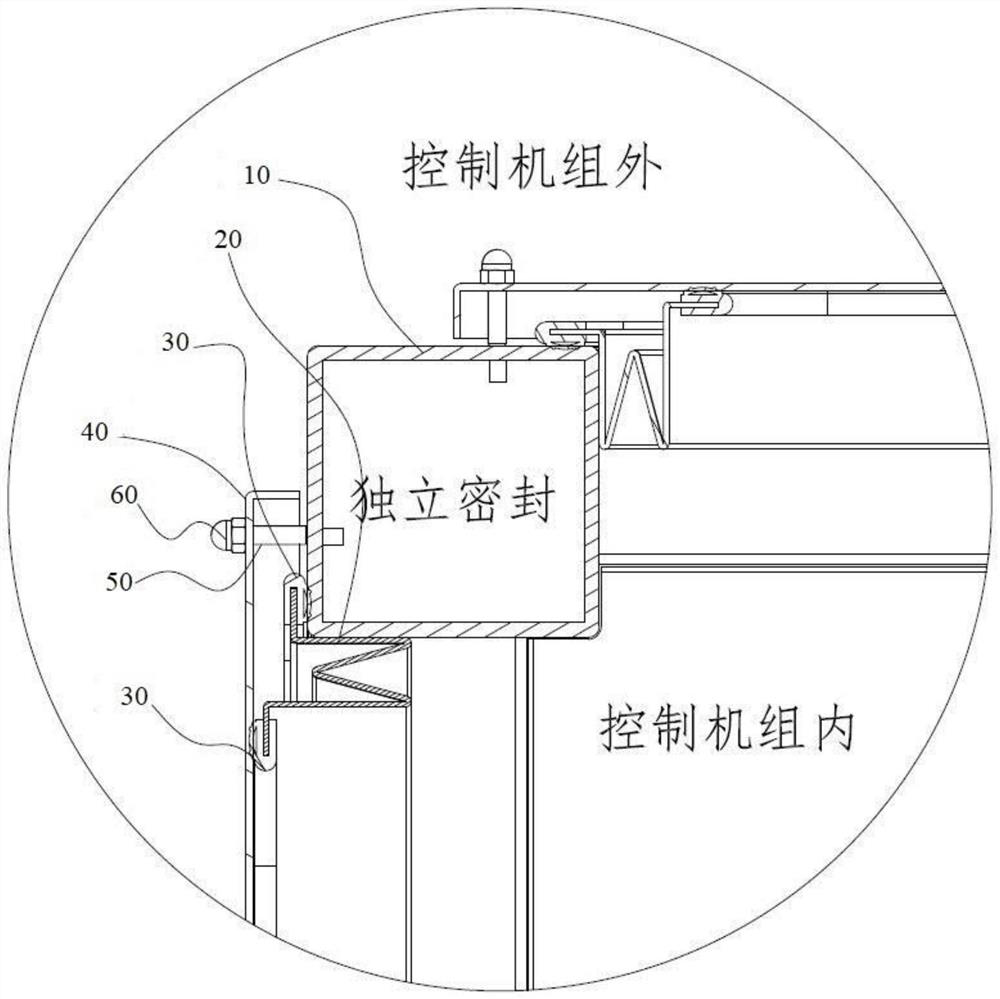

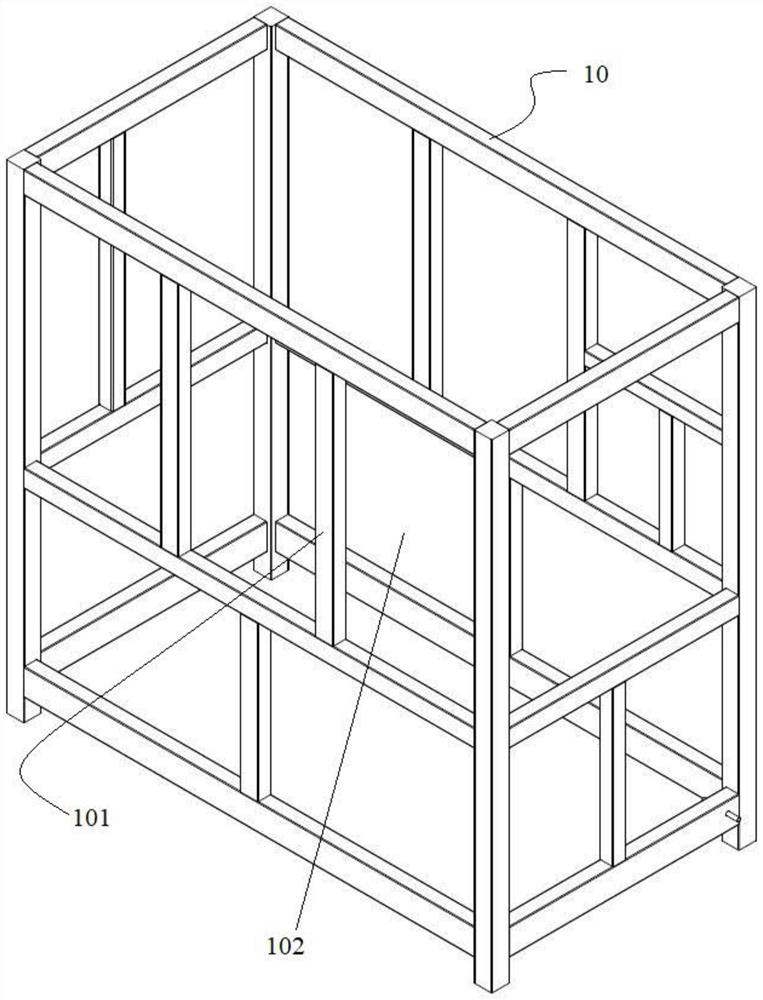

Positive pressure explosion-proof box body and positive pressure explosion-proof unit

ActiveCN114521074AEasy to replacePurpose of improving isolationCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringBody frame

The invention provides a positive pressure explosion-proof box body and a positive pressure explosion-proof unit, and the box body comprises a box body frame which is provided with a movable cover plate installation port; the rubber strip frame is elastic and is arranged at the movable cover plate mounting opening, and the rubber strip frame comprises a main body part forming the frame, and an outer edge and an inner edge which are arranged on the main body part; the sealing rubber strips are arranged on the outer edge and the inner edge; the number of the movable cover plates is at least one, the movable cover plates are detachably installed outside the movable cover plate installation openings, and after the movable cover plates are installed, the movable cover plates apply pressing force towards the inner side of the box body frame to the rubber strip frame by pressing the inner edges so that the outer edges can be tightly attached to the outer surfaces of the framework rectangular pipes. A first seal is formed between the outer edge and the framework rectangular tube, and a second seal is formed between the movable cover plate and the inner edge.

Owner:重庆阿泰可实验仪器有限公司

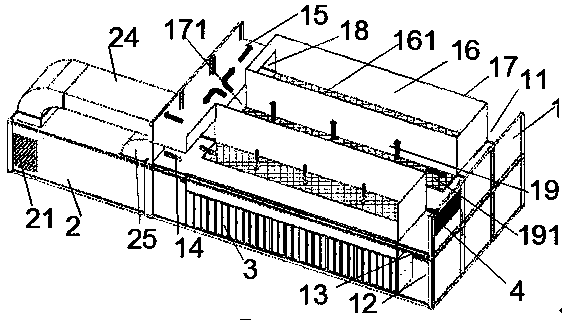

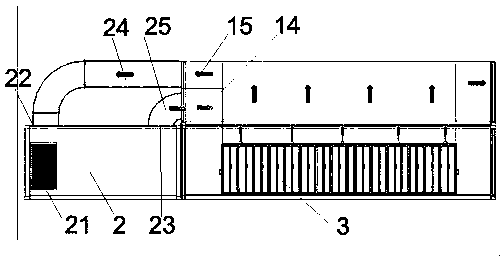

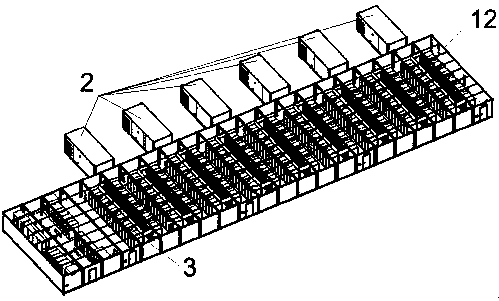

Modular data center

PendingCN108174570AAchieve the purpose of isolationEffective isolationCooling/ventilation/heating modificationsCold airData center

The invention provides a modular data center. The modular data center comprises a casing, an air conditioner case, a first static pressure case, a second static pressure case and a communication cabinet and is characterized in that the casing is divided by a middle separator plate into an airduct static pressure chamber and a bridge stand wiring chamber, the airduct static pressure chamber is arranged above the bridge stand wiring chamber, the air conditioner case is fixed outside the bridge stand wiring chamber, one side of the airduct static pressure chamber close to the air conditioner caseis provided with a cold air channel and the first static pressure case, and the first static pressure case is independently arranged above the cold air channel. The modular data center is advantagedin that the structure is simple, operation is convenient, heat emitted by the communication cabinet can be effectively isolated and energy cycle utilization can be further utilized, refrigeration efficiency is improved, power source use efficiency is improved, energy is saved, the room comfort level is improved, moreover, through factory prefabrication, the field construction is shortened, and manpower, time and economic cost is saved.

Owner:无锡天云数据中心科技有限公司

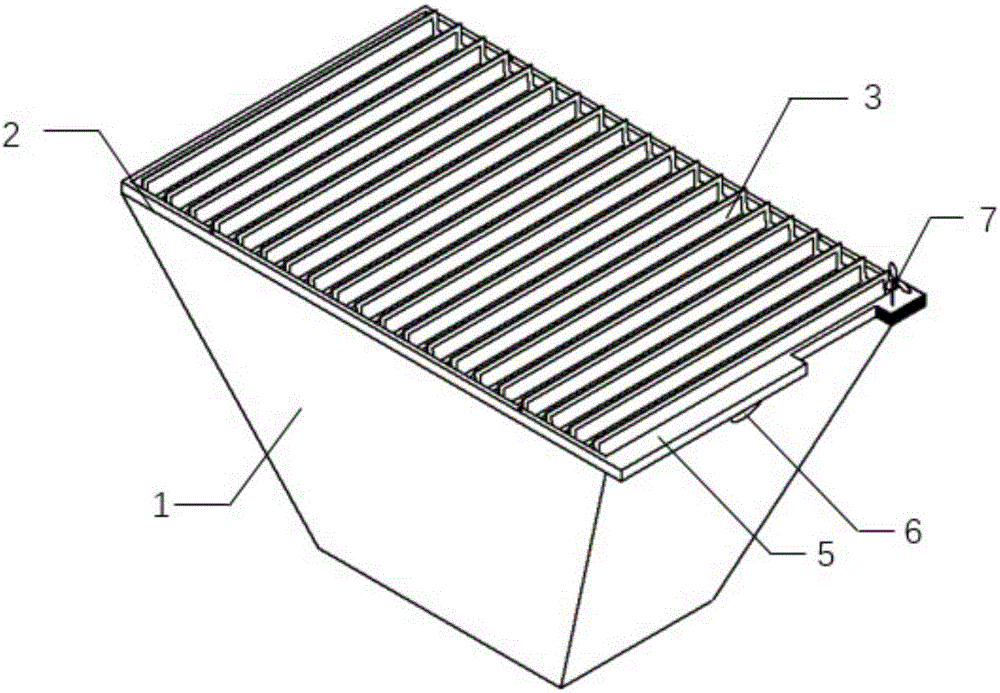

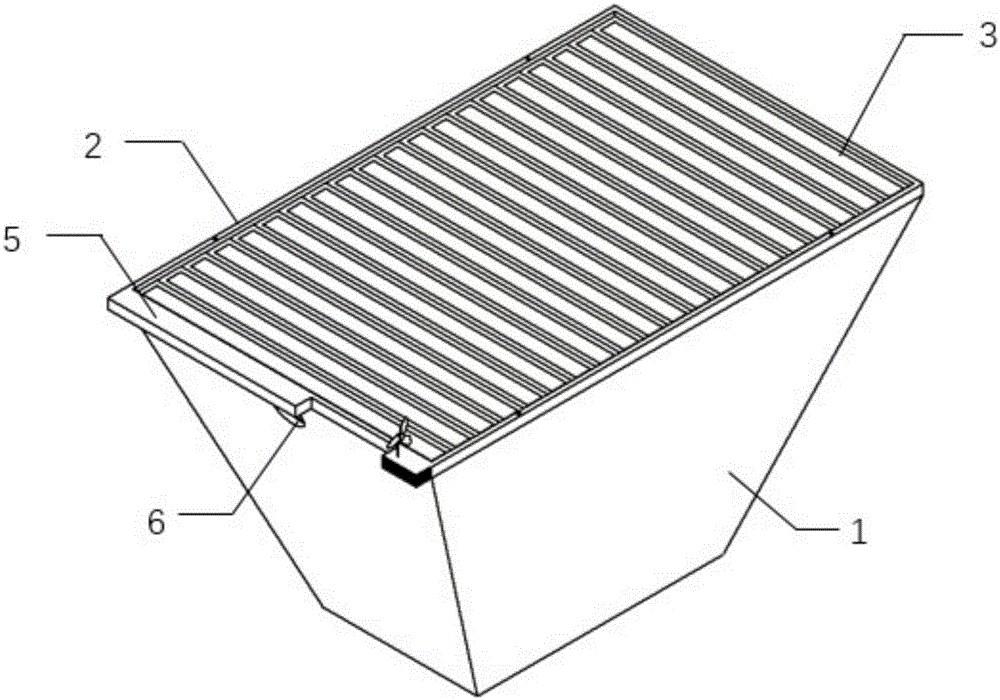

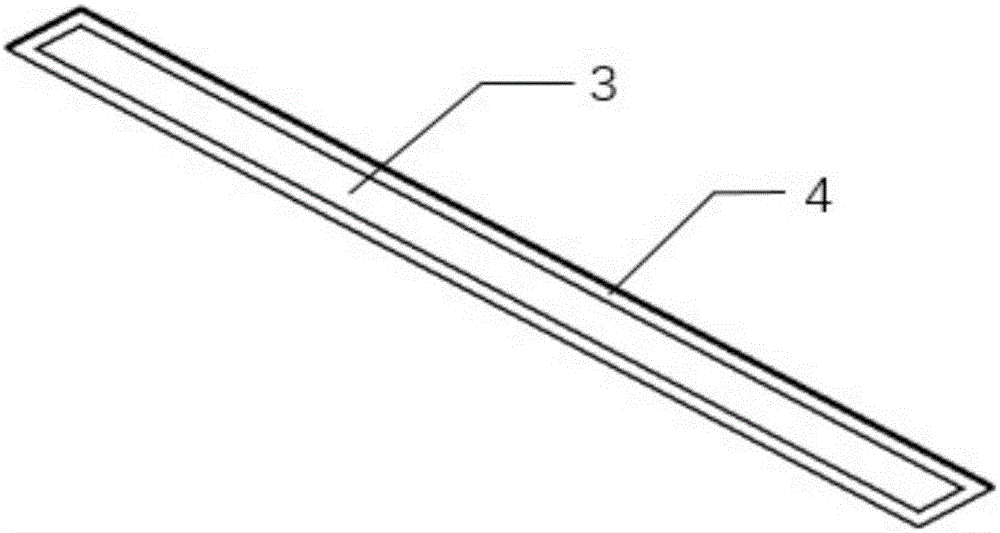

Self-power-supply louver-type solar pond heat storage device

InactiveCN107436042AAchieve the purpose of isolationThe radiation intensity is fully acceptableSolar heating energySolar heat collector controllersSolar pondEngineering

The invention relates to a solar pond heat storage device comprising a pond body, a frame placed at an opening of the pond body and louver flakes with the edges provided with sealing spacers and further comprising a light intensity sensor, a storage battery, a motor and a wind speed monitor or a humidity sensor which are connected with a central control platform. When the sun irradiates in the high sky, the central control platform perceives the solar elevation angle according to the light intensity sensor and sends a signal to the motor so as to control the opening and closing angles of the louver flakes to enable the louver flakes to be parallel to sunlight; when the situation that the environment wind speed is higher than the critical wind speed is monitored by the wind speed monitor or the situation that the environment humidity is higher than the critical humidity is monitored by the humidity sensor, the central control platform sends a signal to the motor so as to control the louver flakes to be completely closed. Operation of the solar pond heat storage device is not affected by overlarge wind power or over-humid weather, and the situation that the heat storage capacity of a solar pond is destroyed by the disadvantageous environment is avoided.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

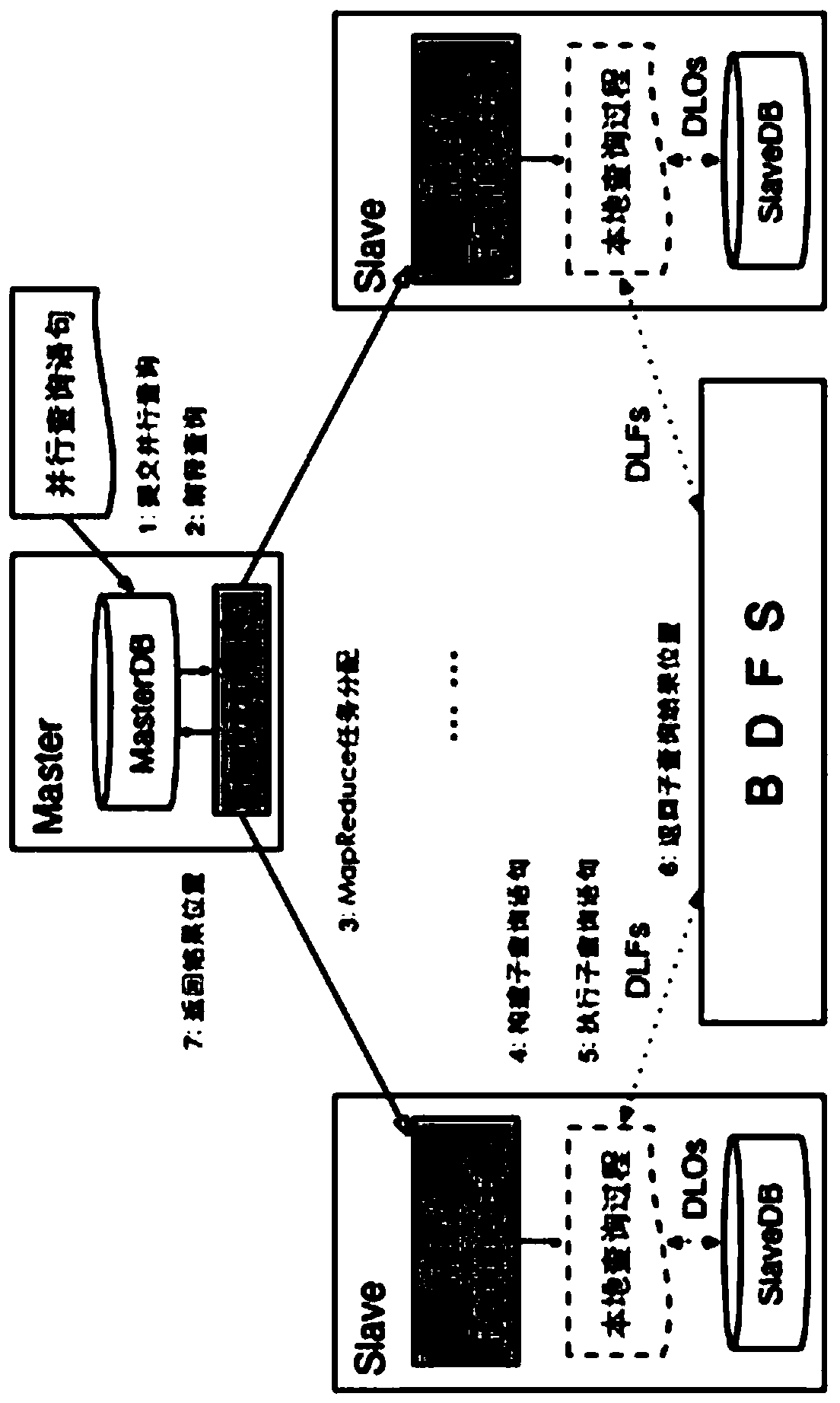

A data query model and method for mapreduce paradigm

ActiveCN104462351BEasy to handleAchieve the purpose of isolationSpecial data processing applicationsDescription formatCentralized database

The invention discloses a data query model and a data query method for a MapReduce pattern, and belongs to the field of processing of information technology. The MapReduce pattern is organically combined with the current database query description language so as to uniformly process parallel and serial query sentences. To meet different parallel query requirements, the invention confirms the basic flow of standard description and processing in an environment where a Hadoop platform is combined with the current integrative database. By the method, distributed data locations stored in different systems are represented uniformly; and the query processes in Map and Reduce stages are described by a UDF (User Defined Function), so as to achieve the goals of performing distributed storage and parallel processing on various data objects according to a description format of the current database query language.

Owner:HOHAI UNIV

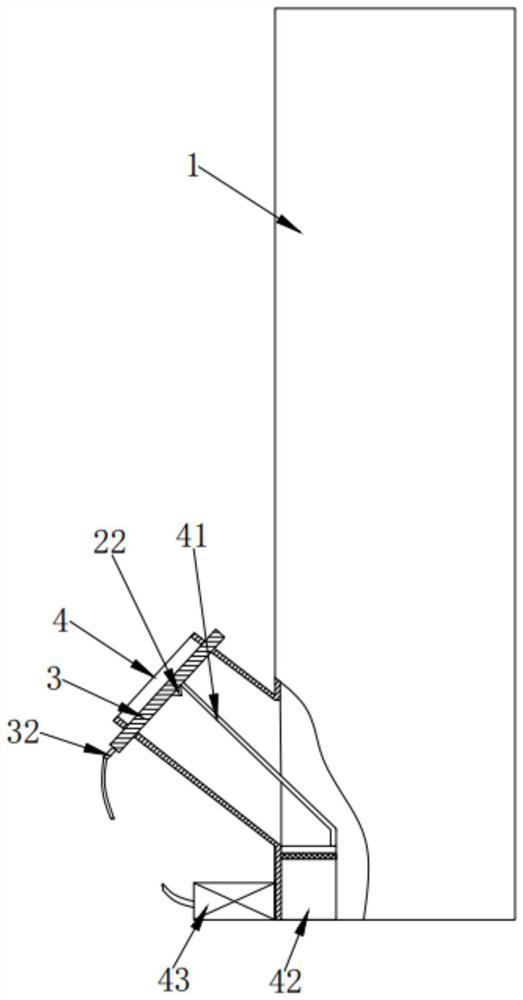

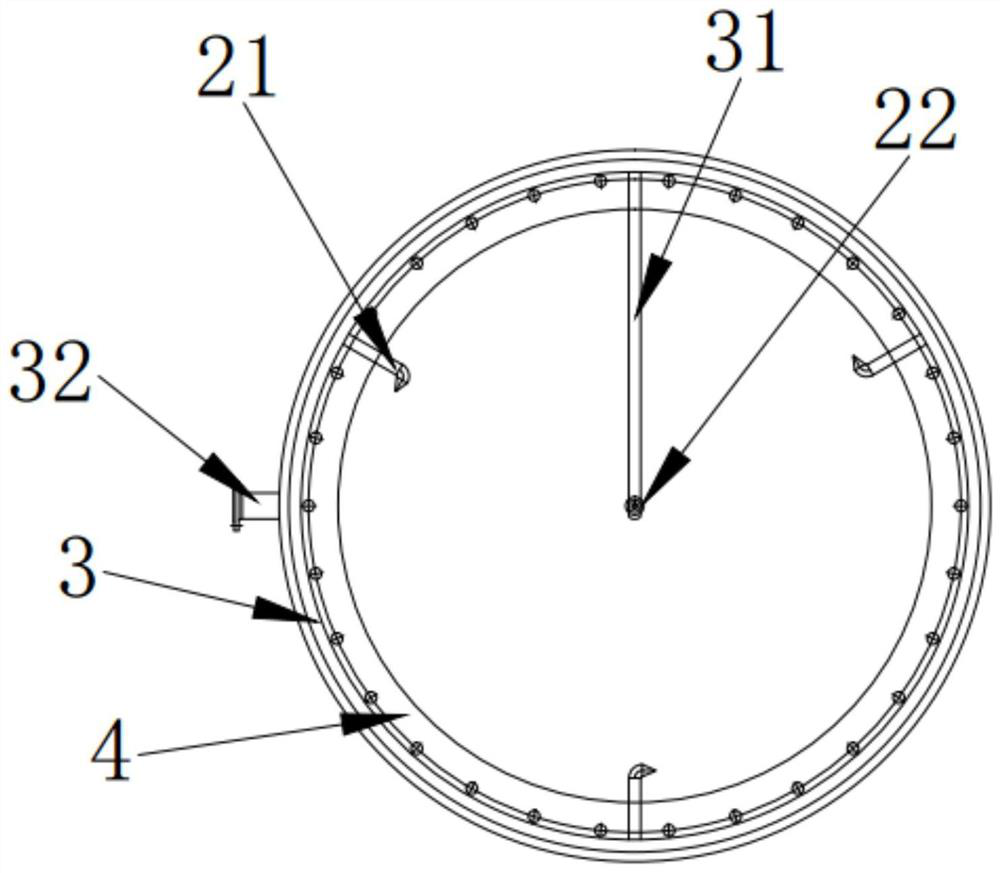

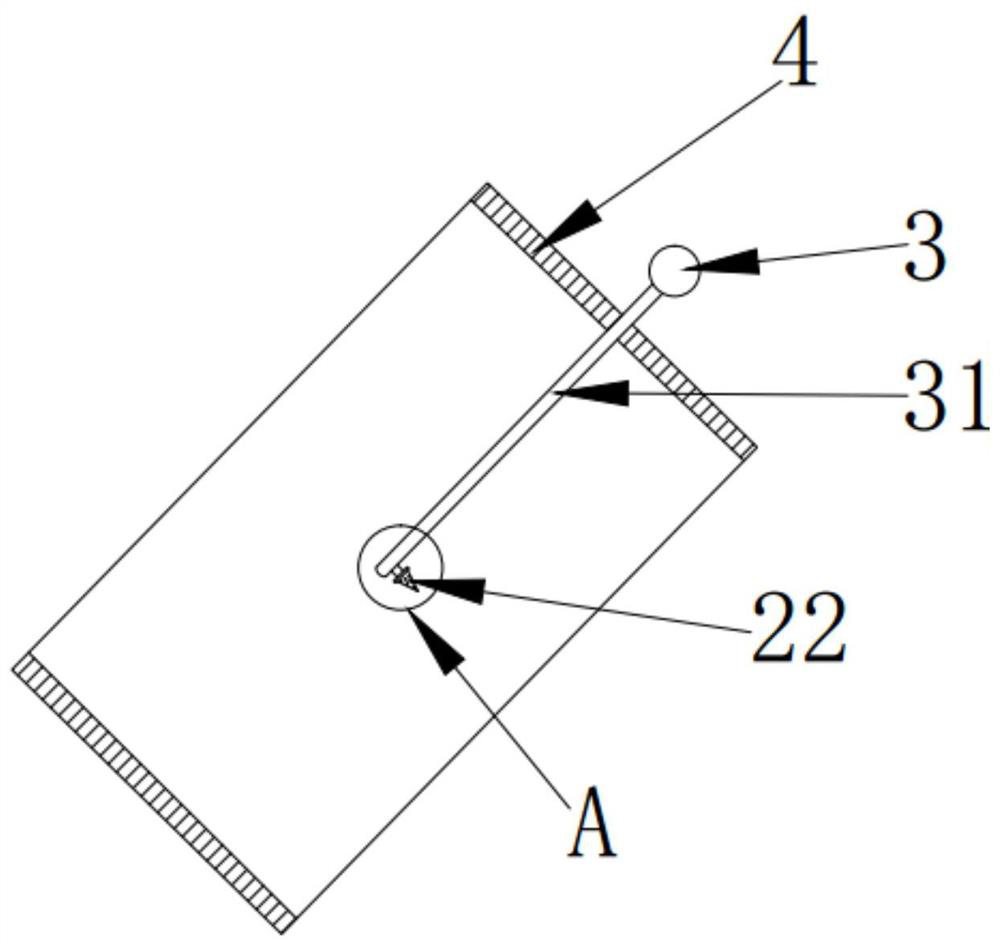

Anti-blocking and cooling device for flue gas inlet of deacidification tower and its use method

ActiveCN109999643BAchieve the purpose of isolationAvoid damageGas treatmentUsing liquid separation agentForeign matterFlue gas

The invention discloses a deacidification tower flue gas inlet anti-blocking and cooling device, which comprises a deacidification tower body (1) and an air inlet (4), and a first nozzle (21) is arranged at the air inlet (4). ), the first nozzle is communicated with the annular water pipe (3), and the annular water pipe (3) is also communicated with a connecting pipe (31), and the connecting pipe (31) is provided with a second nozzle (22); A detachable recovery device is provided on the connecting pipe (31), and a water inlet (32) is provided on the annular water pipe (3). The invention also discloses a method for using the anti-blocking cooling device for flue gas inlet of the deacidification tower. The above-mentioned device and method of use can isolate the high-temperature flue gas from the flue, take away the settled foreign matter in the flue gas in time, avoid the formation of "stalactite"-like blockages on the flue, and reduce the Damage to flue material due to wet and high acid corrosion.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

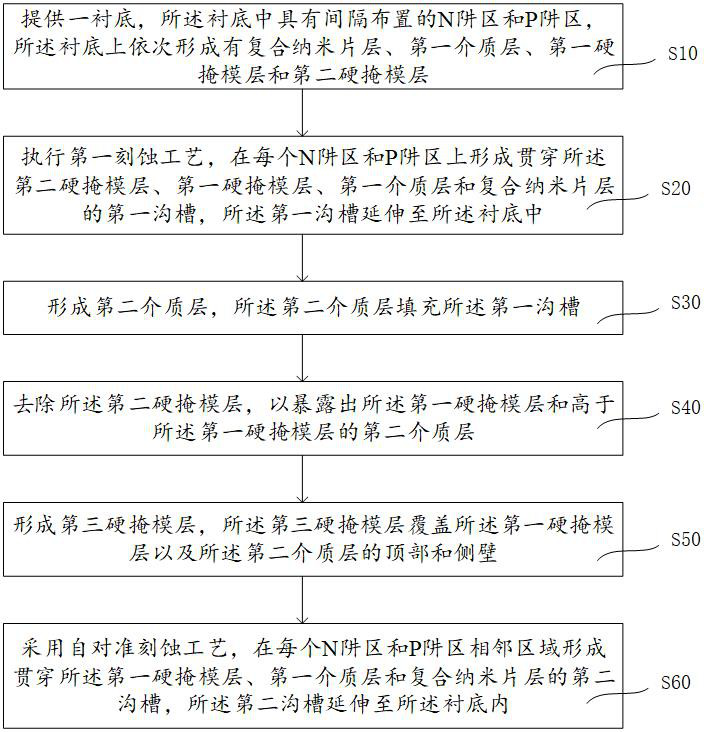

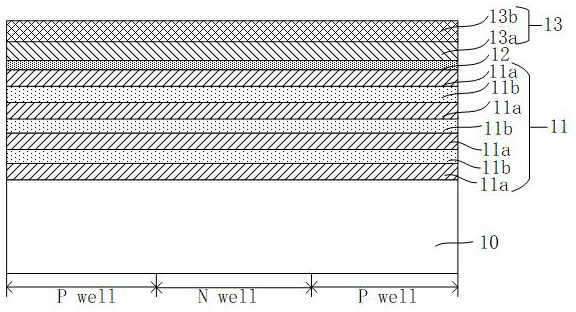

Method of forming semiconductor device

ActiveCN114203636BAchieve the purpose of isolationReduce photolithography stepsSemiconductor/solid-state device manufacturingDevice materialEngineering

The present invention provides a method for forming a semiconductor device, comprising: performing a first etching process, forming a second hard mask layer, a first hard mask layer, The first dielectric layer and the first groove of the composite nanosheet layer, the first groove extends into the substrate; a second dielectric layer is formed, and the second dielectric layer fills the first groove; removing The second hard mask layer to expose the first hard mask layer and the second dielectric layer higher than the first hard mask layer; forming a third hard mask layer, the third hard mask layer The mask layer covers the first hard mask layer and the top and sidewalls of the second dielectric layer; a self-aligned etching process is used to form through the adjacent regions of each N well region and P well region. The first hard mask layer, the first dielectric layer and the second groove of the composite nanosheet layer. A self-aligned etching process is adopted to reduce photolithography steps, reduce costs, and improve transistor performance.

Owner:GUANGZHOU CANSEMI TECH INC

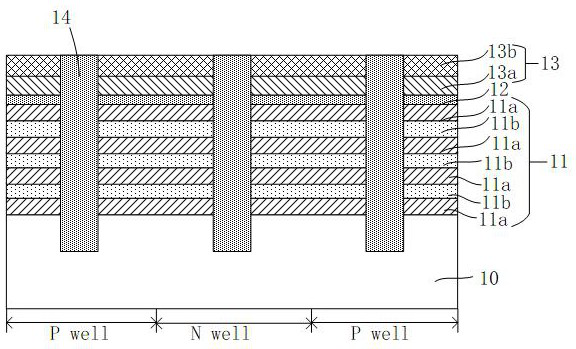

Method and system for producing hydrogen oil by converting ultrahigh-temperature medical solid waste

PendingCN114516617AAchieve recyclingImprove use valueHydrogen separationCarbon compoundsPtru catalystHydrogenation reaction

The invention discloses a method and a system for producing hydrogen oil through ultrahigh-temperature medical solid waste conversion, and the system for producing hydrogen oil through ultrahigh-temperature medical solid waste conversion is used for recovering medical solid waste and then carrying out ultrahigh-temperature gasification to generate mixed gas. Hydrogen and carbon dioxide are prepared from the mixed gas through a reforming reaction and a water-gas shift reaction under the action of a high-selectivity reaction catalyst, purified hydrogen is prepared from the hydrogen through a gas purification process, and hydrogen oil which can be stored at normal temperature and normal pressure is obtained through a hydrogenation reaction of the purified hydrogen and a liquid organic hydrogen storage carrier. According to the comprehensive utilization system for the medical solid waste, various pollution sources generated in the treatment process of the medical solid waste can be fundamentally eradicated, the requirements of all environmental protection standards in the world at present are met, the medical solid waste can be converted into hydrogen energy and various useful substances, and good environmental protection and economic values are achieved.

Owner:武汉恒创能源技术有限公司 +2

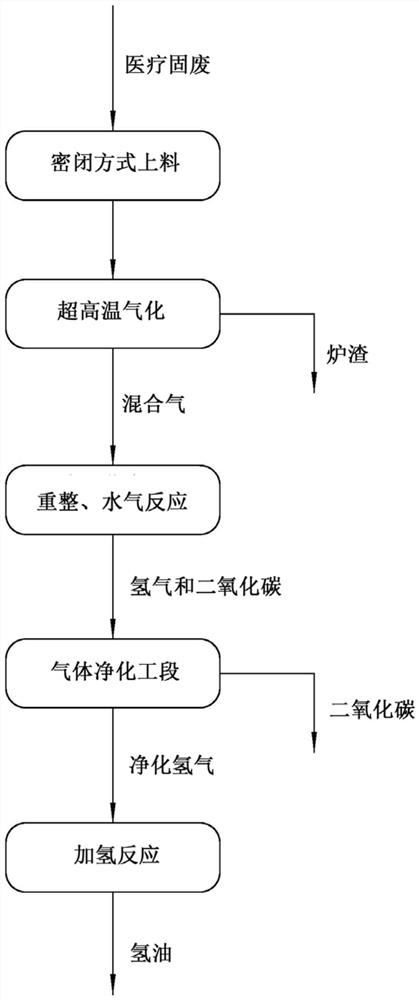

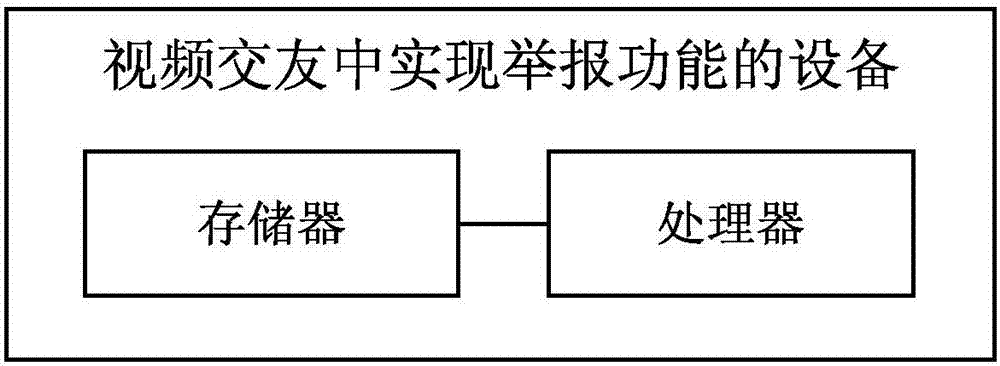

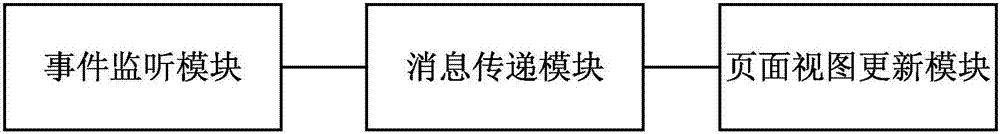

Method for realizing reporting function in video friend making, storage medium, equipment and system

ActiveCN107577540AAchieve the purpose of isolationImprove reusabilityInterprogram communicationTransmissionTreatment resultsControl layer

The invention discloses a method for realizing a reporting function in video friend making, a storage medium, equipment and a system, and relates to the technical field of program development in livestreaming application. The method includes the steps that when a user clicks a reporting button, a reporting function dialogue box pops up, and a UI layer business logic of the dialogue box is packaged in a preset dialogue box monitoring class; when the dialogue box monitoring class monitors that a clicking event of a reporting control is determined / cancelled, a preset information communication protocol in the dialogue box monitoring class is utilized for transmitting corresponding clicking information to a controller of a control layer; if the controller receives the clicking information thatthe reporting control is determined, treatment of reporting and uploading the related business logic is performed, and information of the treatment result is fed back to an Activity page; the Activity page will update view elements on a current interface according to the information of the treatment result. With the method, the business logic with the reporting function and the Activity page canbe decoupled, and therefore the expandability and maintenance of a program are greatly improved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

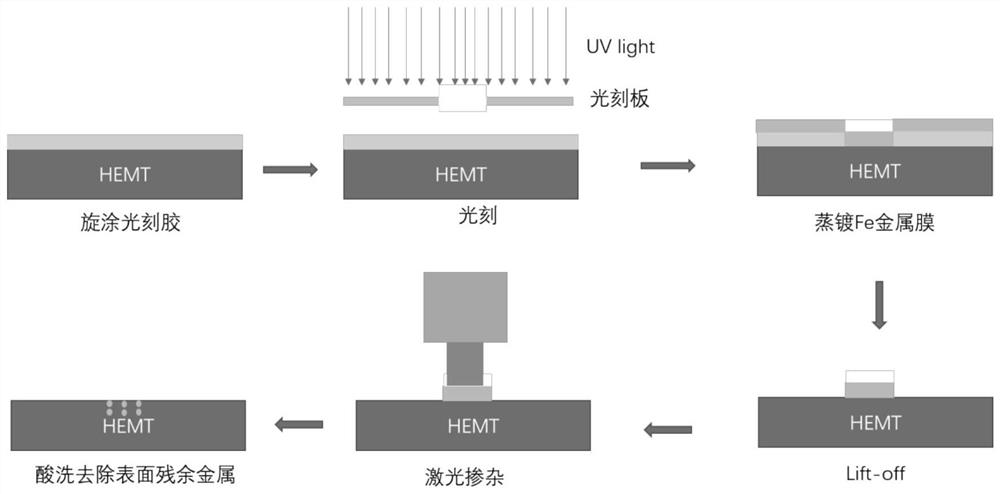

GaN-based device isolation method

PendingCN114267629AAchieve the purpose of isolationFacilitated DiffusionSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryPulse energy

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com