System calibration method based on depth information

A technology of depth information and system calibration, applied in image data processing, instruments, calculations, etc., can solve the problems of low calibration accuracy, affecting measurement accuracy, and correction accuracy, etc. The method is simple and practical, improves calibration accuracy, and ensures accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

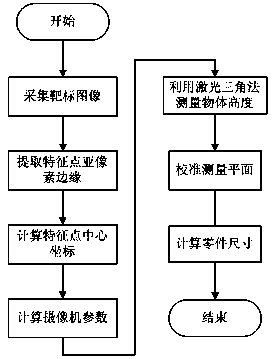

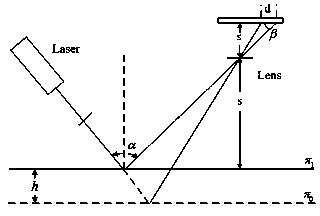

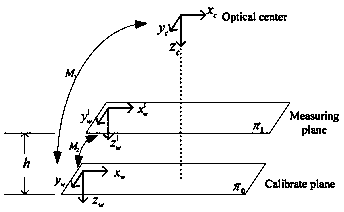

[0023] The flow chart of the present invention is as figure 1 As shown, firstly, the edge detection with adaptive threshold and the polynomial fitting algorithm are used to extract the sub-pixel outline of the feature points, and the center coordinates are obtained by using the ellipse fitting algorithm, and the accurate correspondence with the three-dimensional world coordinates is established, and the camera parameters are obtained by the least square method. Obtain the plane equation of the target. Then the thickness of the part is measured by the point structured light method, and the actual part size is obtained by using the constraints in the depth direction on the basis of the posture obtained by calibration. The specific implementation process of the technical solution of the present invention will be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com