Photoelectric composite cable laid in seabed, and manufacture method thereof

A technology for optoelectronic composite cables and optical fibers, which is used in submarine cables, cable/conductor manufacturing, power cables including optical transmission components, etc., to achieve compact structure, transportation cost savings, and small outer diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

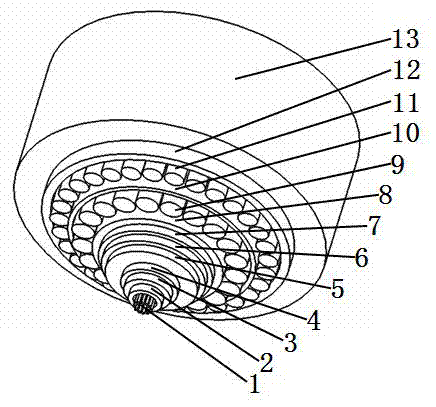

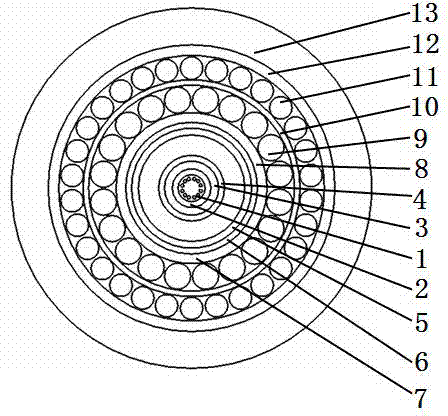

[0029] please see figure 1 and figure 2 , a photoelectric composite cable for submarine laying, is characterized in that it includes 12 optical fibers 1, a loose tube 2 covering the optical fiber, a heat insulation layer 3 wrapped outside the loose tube, and distributed outside the heat insulation layer The conductor layer 4, the insulating layer 5 located outside the conductor layer, the shielding layer 6 located outside the insulating layer, the first protective layer 7 wrapped outside the shielding layer, the inner layer wrapped outside the first protective layer by extrusion Sheath 8, the first armor layer positioned outside the inner sheath, the second protective layer 10 coated outside the first armor layer, the second armor layer positioned outside the second protective layer, extruded plastic wrap The third protective layer 12 covered outside the second armor layer, the outer sheath 13 coated by extrusion molding outside the third protective layer; the first armor la...

Embodiment 2

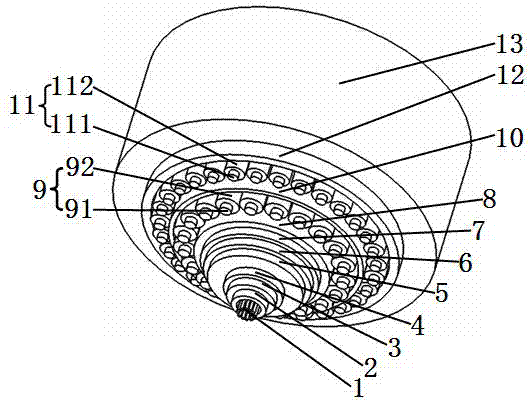

[0032] please see image 3 and Figure 4, a photoelectric composite cable for submarine laying, is characterized in that it includes 12 optical fibers 1, a loose tube 2 covering the optical fiber, a heat insulation layer 3 wrapped outside the loose tube, and distributed outside the heat insulation layer The conductor layer 4, the insulating layer 5 located outside the conductor layer, the shielding layer 6 located outside the insulating layer, the first protective layer 7 wrapped outside the shielding layer, the inner layer wrapped outside the first protective layer by extrusion Sheath 8, the first armor layer positioned outside the inner sheath, the second protective layer 10 coated outside the first armor layer, the second armor layer positioned outside the second protective layer, extruded plastic wrap The third protective layer 12 covered outside the second armor layer, the outer sheath 13 coated by extrusion molding outside the third protective layer; the first armor lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com