Unit pixel, array substrate, display apparatus, and manufacture methods thereof

一种阵列基板、显示装置的技术,应用在半导体/固态器件制造、电气元件、半导体器件等方向,能够解决漏电流大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

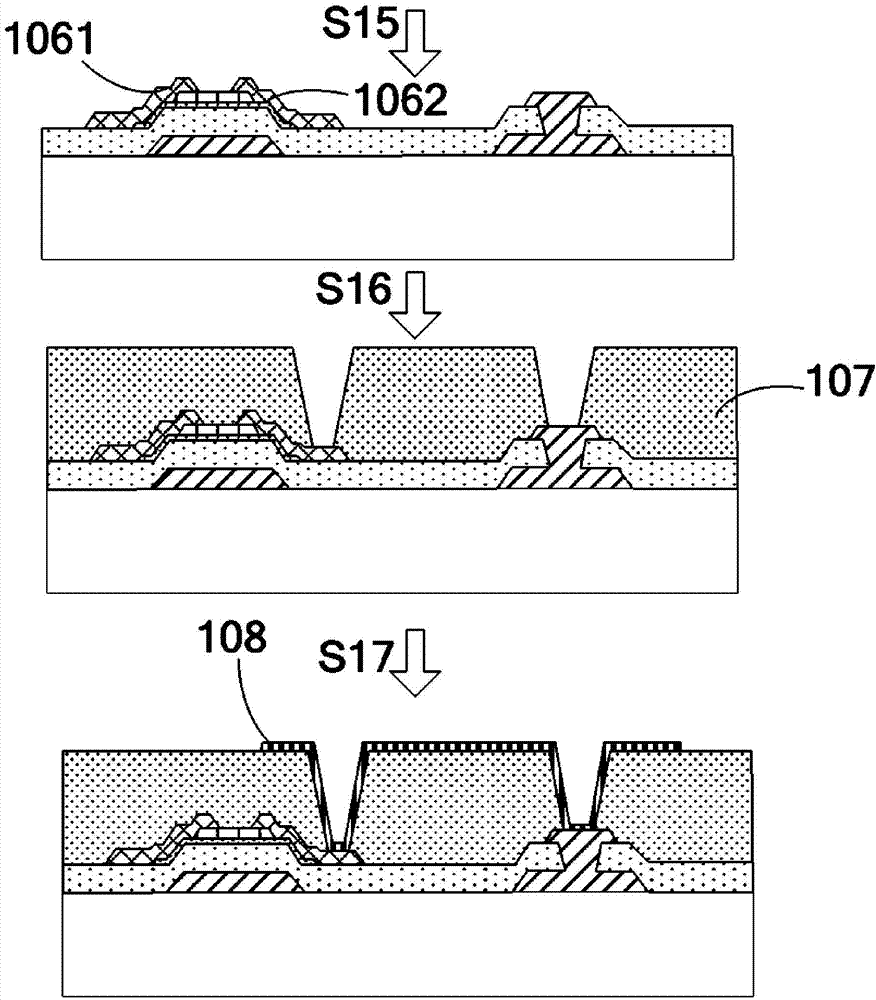

[0064] figure 2 It is a top view of a unit pixel of a first embodiment of the present invention after forming a gate line and a gate of a TFT. Such as figure 2 As shown, the obliquely shaded area is the grid line area 1 and 1', and the area surrounded by the grid line area and the dotted line is the area of a unit pixel. In this view, there are also gate regions 2 and 3 forming TFTs including region 2 of the gate switching TFT and region 3 of the data driving TFT.

[0065] In this embodiment, the material for forming the gate line in the above gate line region is a stacked layer structure, which respectively includes a first MoW layer, a Cu layer and a second MoW layer from bottom to top. And the gate electrode formed in the gate region of the TFT is composed of the first MoW layer.

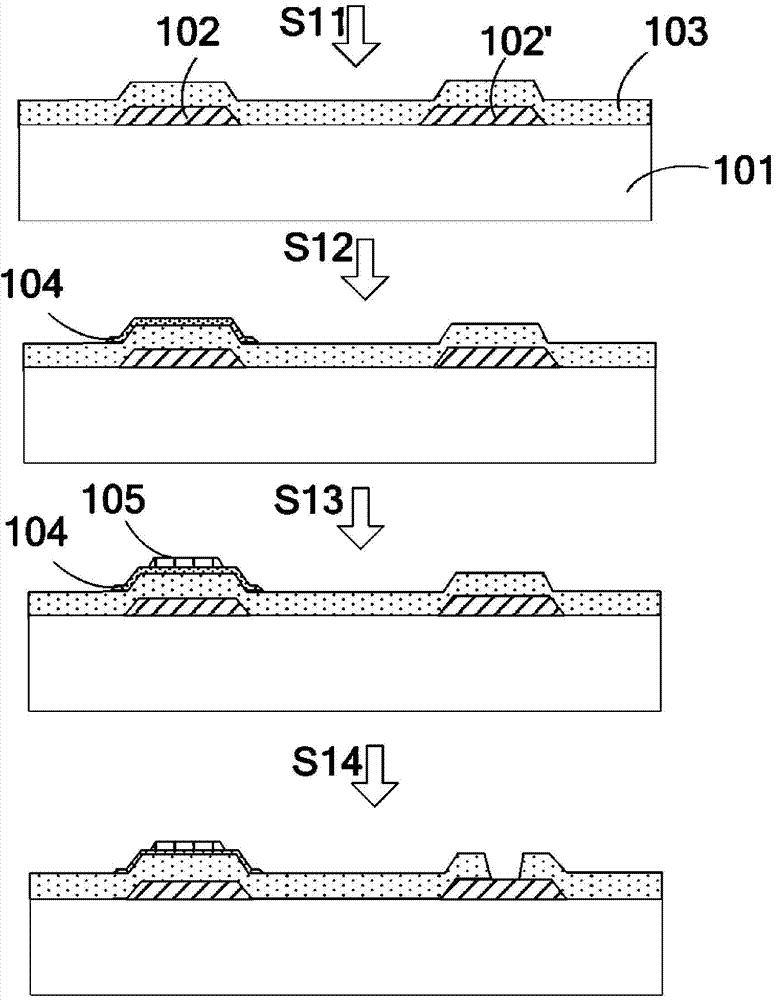

[0066] exist figure 2 An active layer and source-drain electrode lines are then formed on the unit pixel shown, so as to complete the fabrication of the entire unit pixel. image 3 is a...

no. 2 example

[0082] The second embodiment also relates to a unit pixel structure of an array substrate of a display device and a manufacturing method thereof. The source-drain electrode line of the unit pixel adopts a MoW / Cu / MoW stack structure, while the source-drain electrode of the TFT uses a layer of MoW.

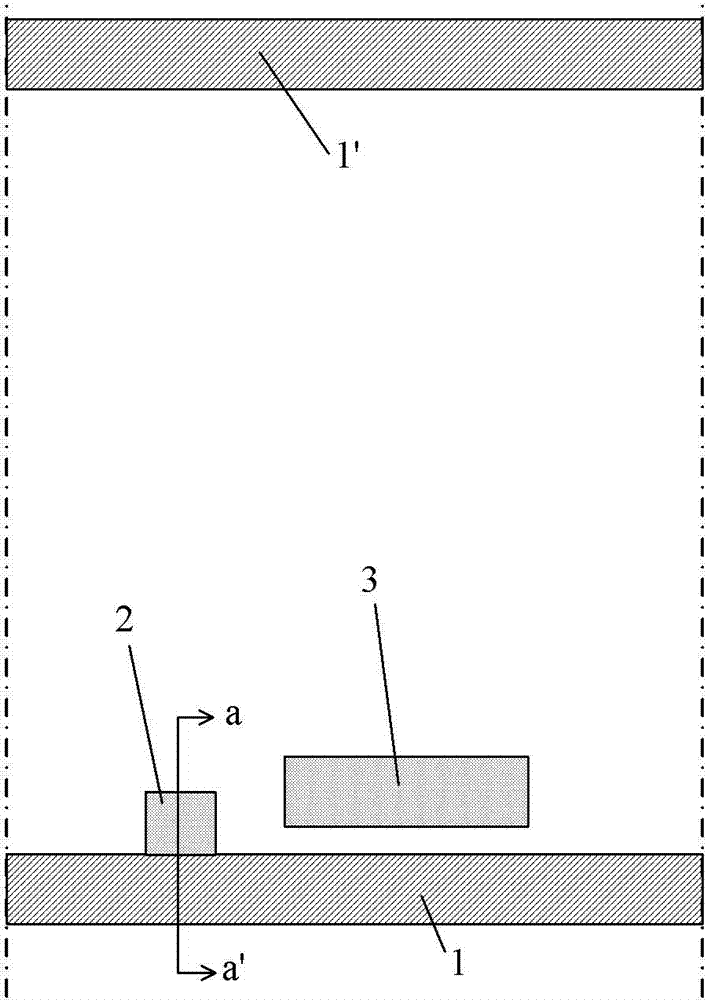

[0083] Figure 5It is a top view without forming source-drain electrode lines and source-drain electrodes of TFT in this embodiment. As shown in the figure, the gate line has been formed in the gate line area 4 and 4', and the gate area 5, 6 of the TFT forms the gate of the TFT, wherein the TFT gate area 5 is the gate switch TFT The area where the gate is located, the TFT gate area 6 is the area where the gate of the data-driven TFT is located.

[0084] In the present invention, the source-drain electrode lines include data lines and VDD lines. The data line is used to provide data driving, and the VDD line is used to provide a current source line for emitting light to the OLED. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com