Ultrasound probe

An ultrasonic and acoustic impedance technology, applied in the field of ultrasonic probes, can solve problems such as complex wiring structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

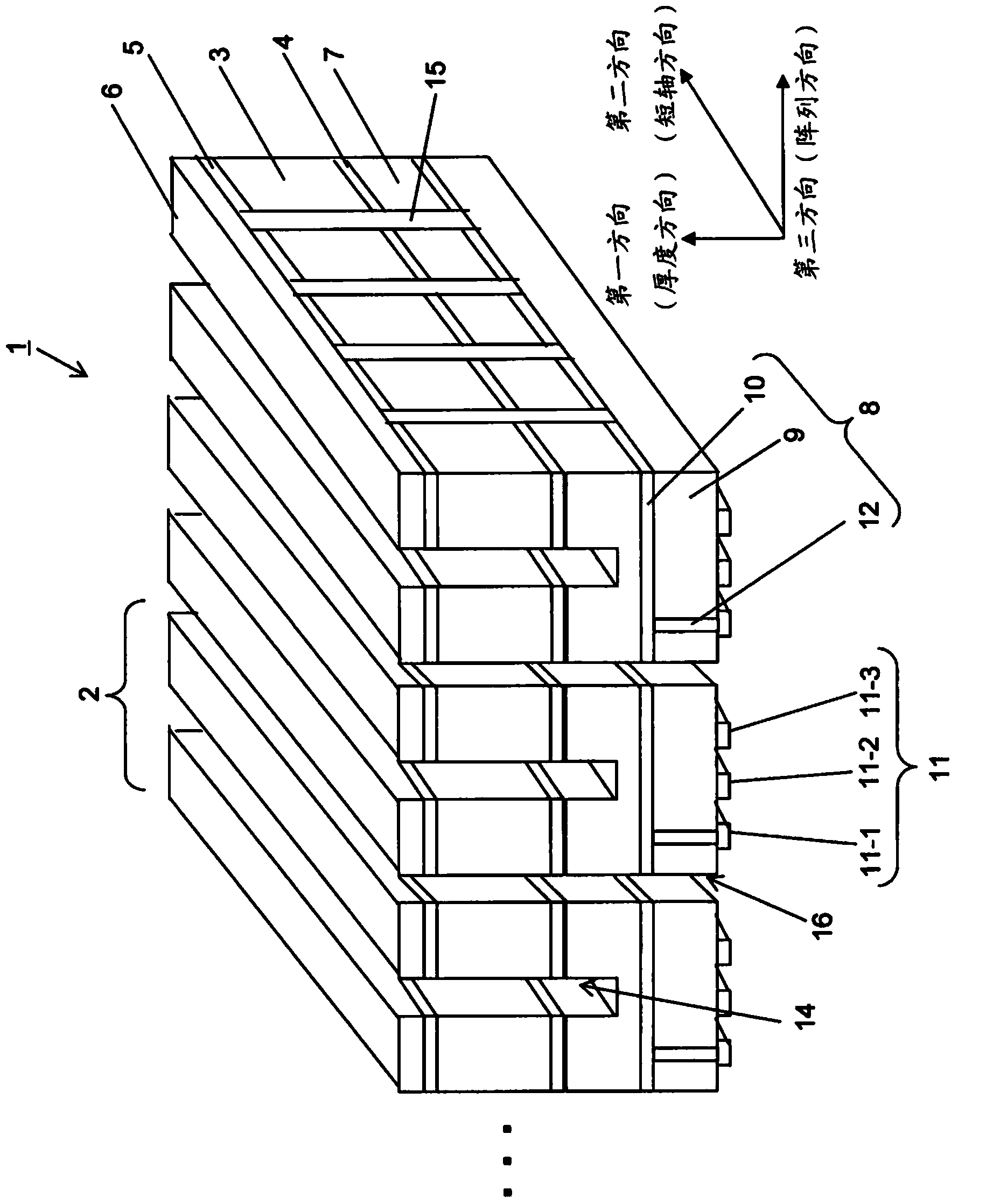

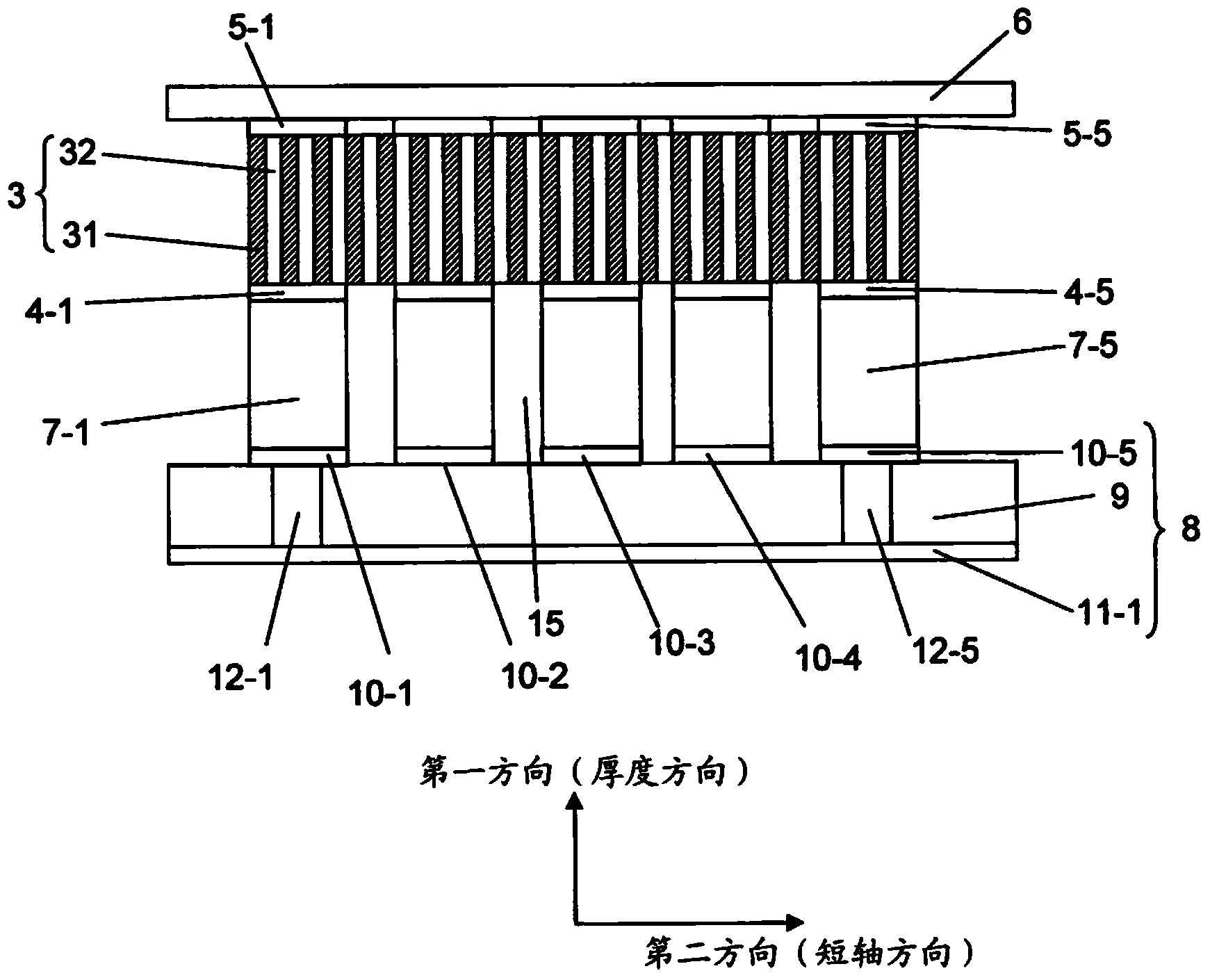

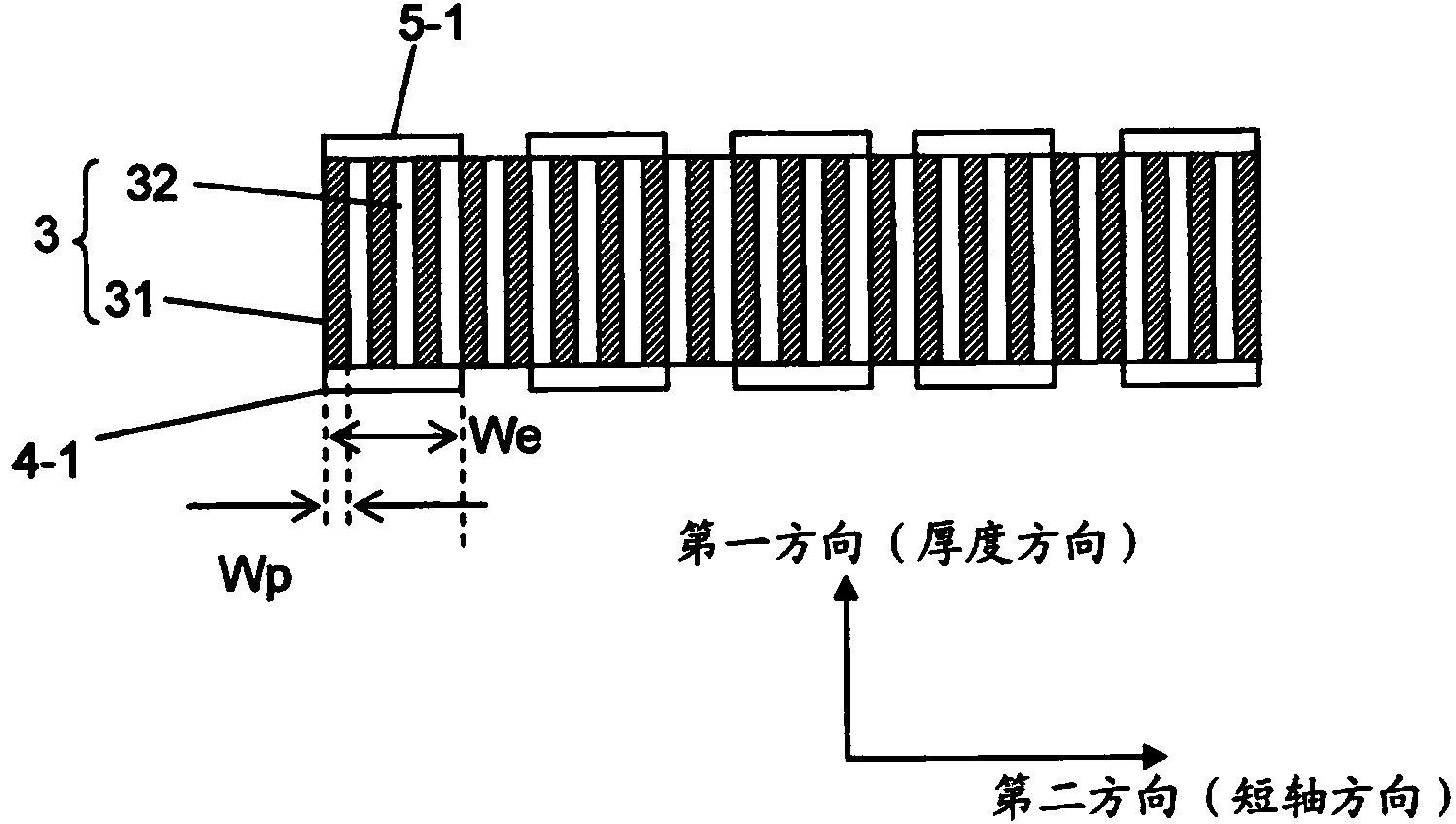

[0053] figure 1 It is a perspective view showing the ultrasonic probe according to the first embodiment of the present invention. figure 1 The ultrasonic probe 1 shown is used in contact with a subject such as a living body. The ultrasonic probe 1 applies an electric signal to the piezoelectric body 3 in the ultrasonic probe 1 to irradiate the subject with ultrasonic waves. A transducer that converts reflected ultrasonic waves from the subject into electrical signals. Such as figure 1 As shown, the ultrasonic probe 1 has: a piezoelectric body 3, a second electrode 4, a first electrode 5, a ground layer 6, an intermediate layer 7, a double-sided FPC 8, a third electrode 11, a first groove 14, and a second groove 15. The third groove 16, the back surface component (not shown), multiple integration layers (not shown) and the lens (not shown).

[0054] If an ultrasonic diagnostic device or an ultrasonic probe is applied between the first electrode (ground electrode) 5 and th...

no. 2 approach

[0121] Figure 23 It is a perspective view showing an ultrasonic probe according to a second embodiment of the present invention. The ultrasonic probe 111 of the second embodiment has a single-sided FPC 13 instead of the double-sided FPC 8 of the ultrasonic probe 1 of the first embodiment. Other than that, the second embodiment is the same as the first embodiment, in that Figure 23 in, right with figure 1 The same structural components are marked with the same symbols.

[0122] Single-sided FPC 13 has third electrode 11 and insulating layer 9 extending in the second direction (short axis direction). As the insulating layer 9, a polyimide film, a polyester film, or the like can be used. Like the double-sided FPC 8 , the single-sided FPC 13 is commercially available in which the third electrode 11 and the insulating layer 9 are pre-stacked, so it is the easiest to use.

[0123] On a part of the third electrode 11 of the single-sided FPC13, in the second direction (minor a...

no. 3 approach

[0133] Figure 31 It is a perspective view showing an ultrasonic probe according to a third embodiment of the present invention. In the ultrasonic probe 111 of the second embodiment, the insulating layer 19 is provided on a part of the third electrode 11, but in this embodiment, as Figure 31 As shown, an insulating layer 29 is provided on the intermediate layer 7 in the second direction (short axis direction). Other than that, the third embodiment is the same as the second embodiment, in Figure 31 in, right with Figure 23 The same structural components are marked with the same symbols.

[0134] When the intermediate layer 7 is formed of a metal material such as aluminum, the insulating layer 29 is formed by selectively performing an alumite treatment. Also, in the case where the intermediate layer 7 is formed of an insulating material, as Figure 6 and Figure 7 As shown, by selectively forming a conductive layer, the portion of the intermediate layer 7 where no condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com