Composite low-mercury complex catalyst used in vinyl chloride synthesis, and preparation method thereof

A catalyst and complex technology, applied in the field of compound low-mercury complex catalyst and its preparation, can solve the problems of rapid deactivation, environmental pollution, easy loss, etc., and achieve the effects of increasing reaction activity and reducing sublimation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

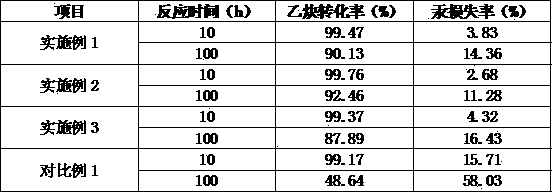

Examples

Embodiment 1

[0023] (1) Dissolve 0.2715g (0.001mol) of mercuric chloride in dilute hydrochloric acid, add it to 10g of activated carbon, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain a mercuric chloride catalyst.

[0024] (2) Dissolve 0.2641g (0.001mol) of 18-crown-6 in dilute hydrochloric acid under stirring, add dropwise the mercuric chloride catalyst prepared in step (1) after clarification, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours. A mercury complex catalyst was obtained.

[0025] (3) Dissolve 0.35g of potassium chloride and 0.20g of ferric chloride in dilute hydrochloric acid, add the mercury complex catalyst prepared in step (2) after clarification, soak at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain the compound low Mercury complex catalyst.

Embodiment 2

[0027] (1) Dissolve 0.4072g (0.0015mol) of mercuric chloride in dilute hydrochloric acid, add it to 10g of activated carbon, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain a mercuric chloride catalyst.

[0028] (2) Dissolve 3.0g (0.0015mol) PEG2000 in dilute hydrochloric acid under stirring, add dropwise the mercuric chloride catalyst prepared in step (1) after clarification, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain mercury complex material catalyst.

[0029] (3) Dissolve 0.6820g of copper chloride in dilute hydrochloric acid, add the mercury complex catalyst prepared in step (2) after clarification, soak at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain a compound low-mercury complex catalyst.

Embodiment 3

[0031] (1) Dissolve 0.3258g (0.0012mol) of mercuric chloride in dilute hydrochloric acid, add it to 10g of activated carbon, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain a mercuric chloride catalyst.

[0032] (2) Dissolve 1.3216g (0.006mol) of 15-crown-5 in dilute hydrochloric acid under stirring, add dropwise the mercuric chloride catalyst prepared in step (1) after clarification, impregnate at room temperature for 8 hours, and dry at 120°C for 8 hours. A mercury complex catalyst was obtained.

[0033] (3) Dissolve 0.12g of ferric chloride and 0.4089g of zinc chloride in dilute hydrochloric acid, add the mercury complex catalyst prepared in step (2) after clarification, immerse at room temperature for 8 hours, and dry at 120°C for 8 hours to obtain the compound low Mercury complex catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com