Forging forming method of the third generation nuclear power coolant pump casing

A coolant pump and forging forming technology, which is applied in the forming field of metal materials, can solve problems such as irregular shapes, achieve good forging and compacting effects, good economical efficiency, and reduce the difficulty of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

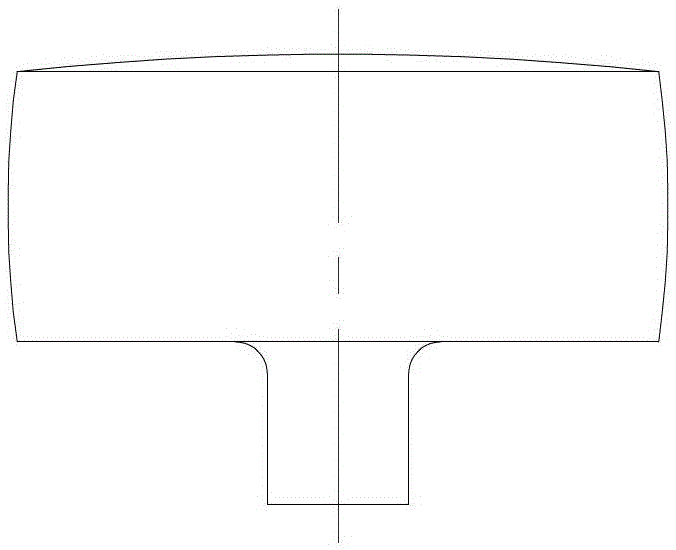

[0034] The forging forming method of the third generation nuclear power coolant pump casing of the present invention is used to form such as Figure 4 The pump casing forging shown with nozzles at both ends consists of the following steps:

[0035] The first step is to upsetting and elongating;

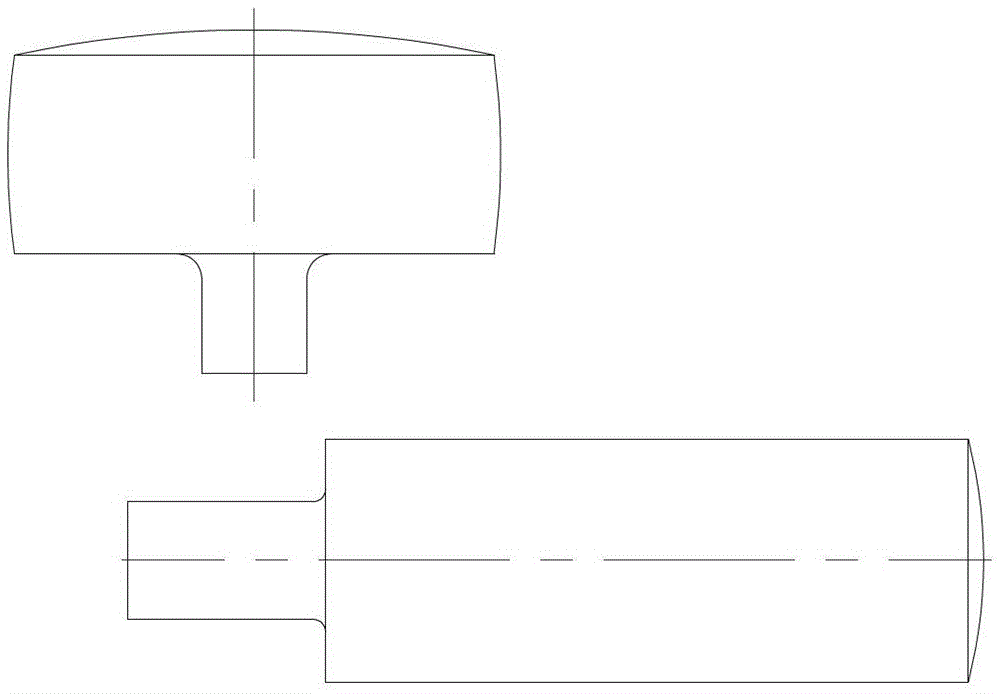

[0036] Upsetting the billet once, and then performing a strong pressing and drawing after upsetting to form a figure 1 the shape shown;

[0037] Control the height-to-diameter ratio of the blank during an upsetting process to meet the ratio of height to diameter ≥ 1;

[0038] The draw ratio of one-time strong pressure draw is ≥2;

[0039] The second step, secondary upsetting and elongation;

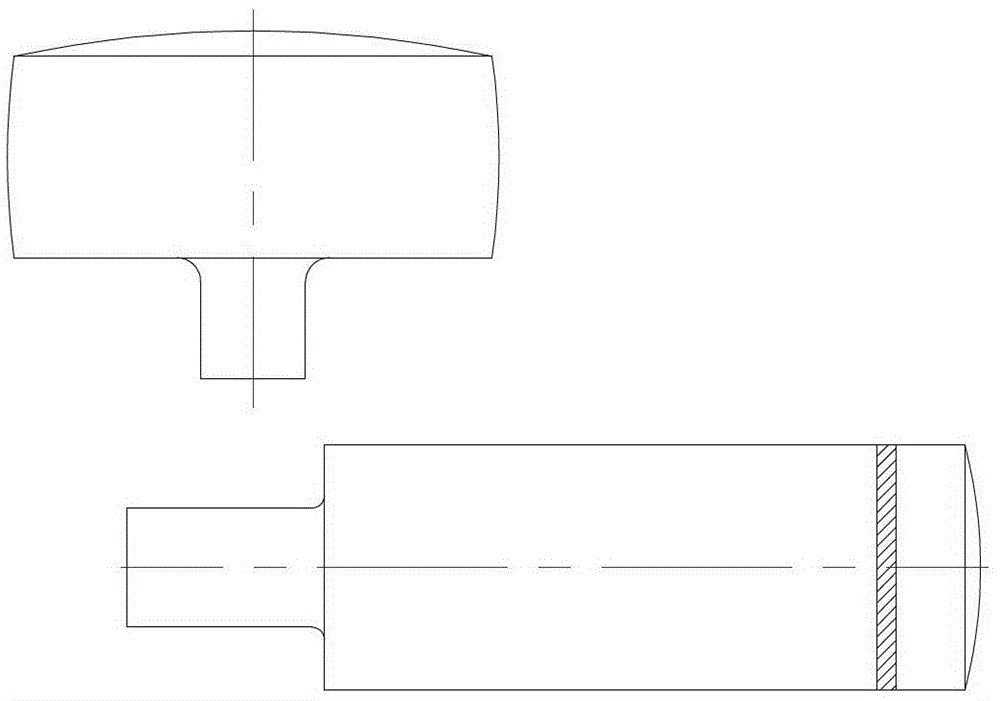

[0040] The billet is subjected to secondary upsetting, and after upsetting, it is subjected to secondary strong pressing and drawing to form a figure 2 the shape shown;

[0041] cutting the bottom after elongation to remove defects in the deposited zone of the ingot;

[0042] After cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com