Automatic film sticking equipment

A film lamination equipment and automatic technology, applied in packaging, workpiece clamping devices, manufacturing tools, etc., can solve the problems that the protective film cannot be absorbed smoothly, the protective film is not absorbed smoothly, and the yield rate is not high, so as to improve the film lamination yield rate, Eliminate air bubbles and fit smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

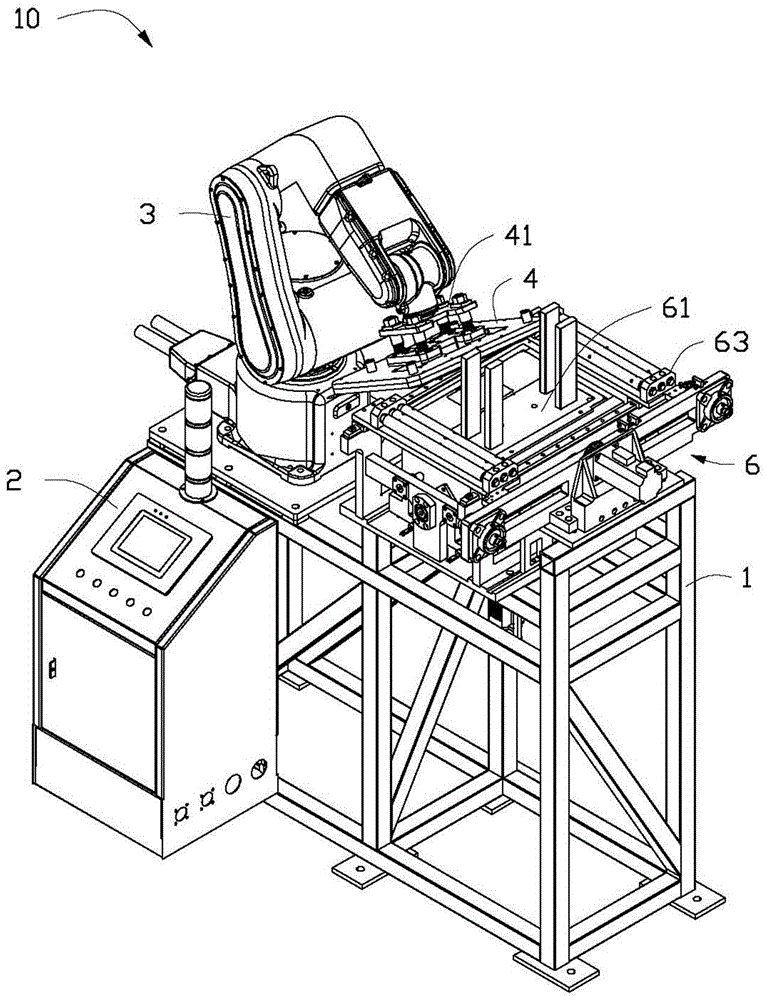

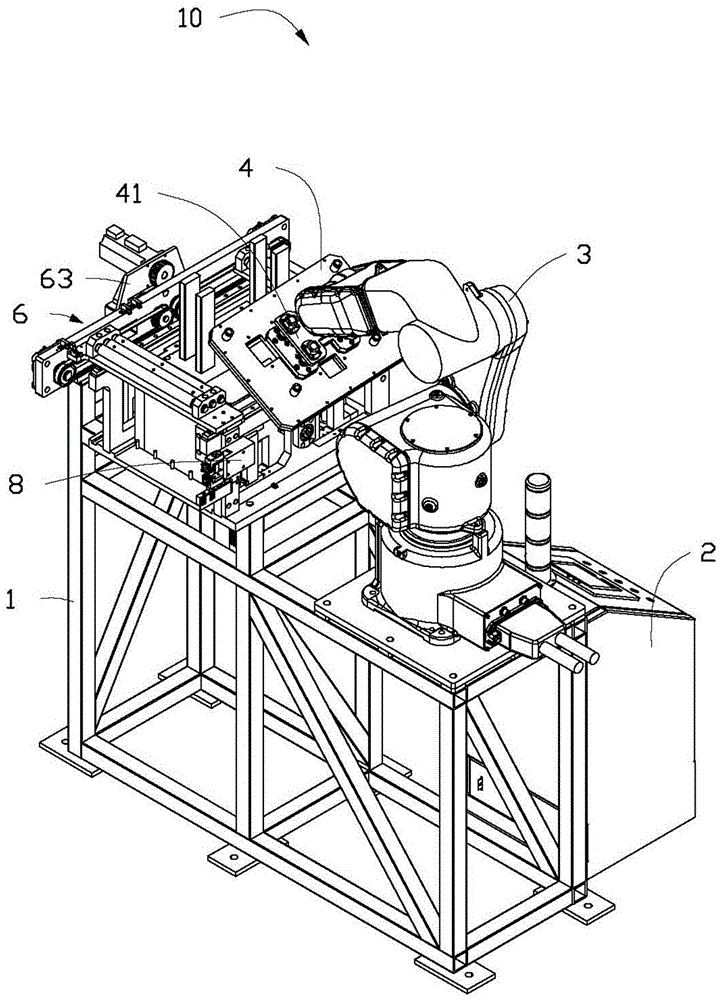

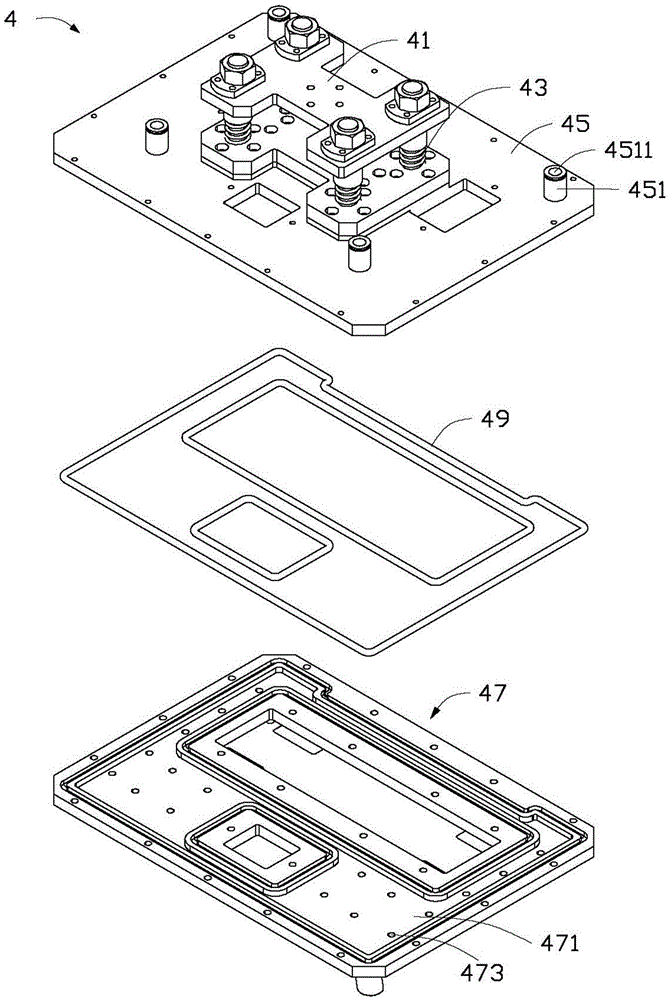

[0018] Please also refer to figure 1 and figure 2 , the automatic film sticking equipment 10 provided by the embodiment of the present invention is set next to the production line (not shown in the figure), and it is used for performing film sticking operations on workpieces (not shown in the figure) on the line. The automatic film sticking equipment 10 includes a frame 1 , a console 2 , a manipulator 3 , a laminating device 4 , a storage device 6 and a degreasing film device 8 . The frame 1 is installed in the workplace, the console 2 is arranged adjacent to the frame 1, the manipulator 3 is installed on the frame 1 and adjacent to the console 2, the bonding device 4 is installed at the execution end of the manipulator 3, and the storage device 6 Adjacent to the manipulator 3 is arranged on the frame 1 , and the degreasing film device 8 is arranged on the side of the storage device 6 close to the manipulator 3 .

[0019] The operation program is embedded in the console 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com