engine driven work machine

An engine-driven, working machine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as difficult water vapor intake into the steam intake port, difficulty in ensuring the amount of distilled water generated, and difficulty in ensuring the amount of water vapor condensation , to achieve excellent heat insulation, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Hereinafter, when describing the examples, in the drawings, "Fr", "Rr", "L" and "R" represent the front, rear, left and right sides.

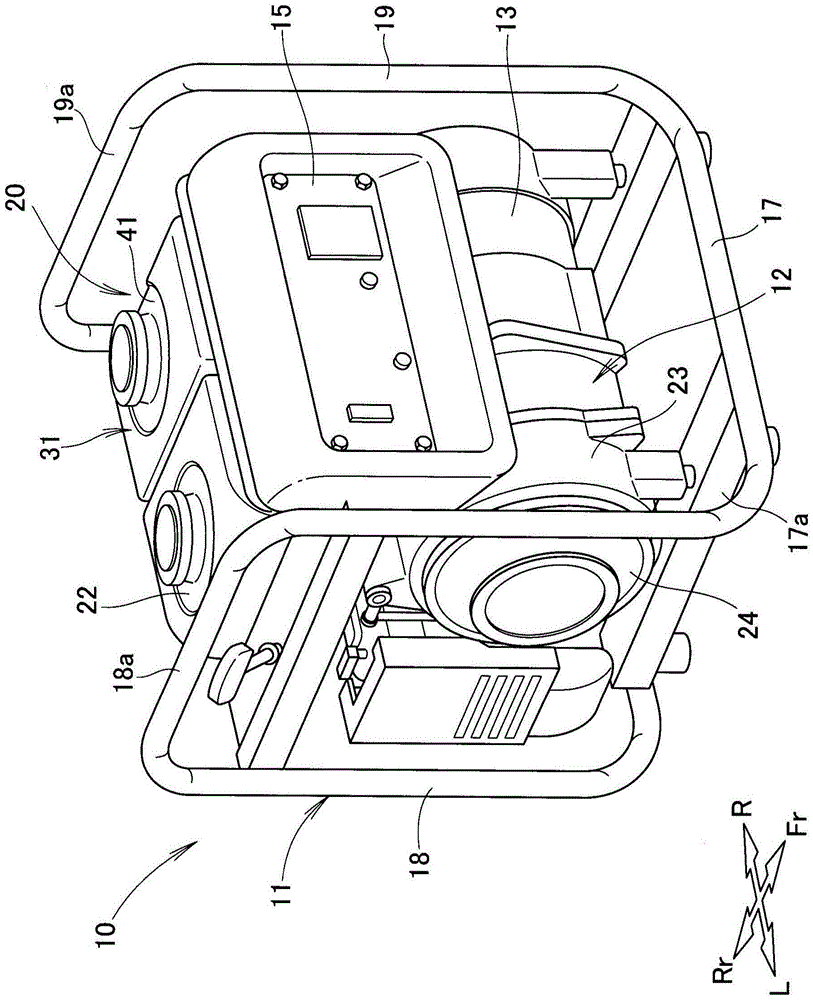

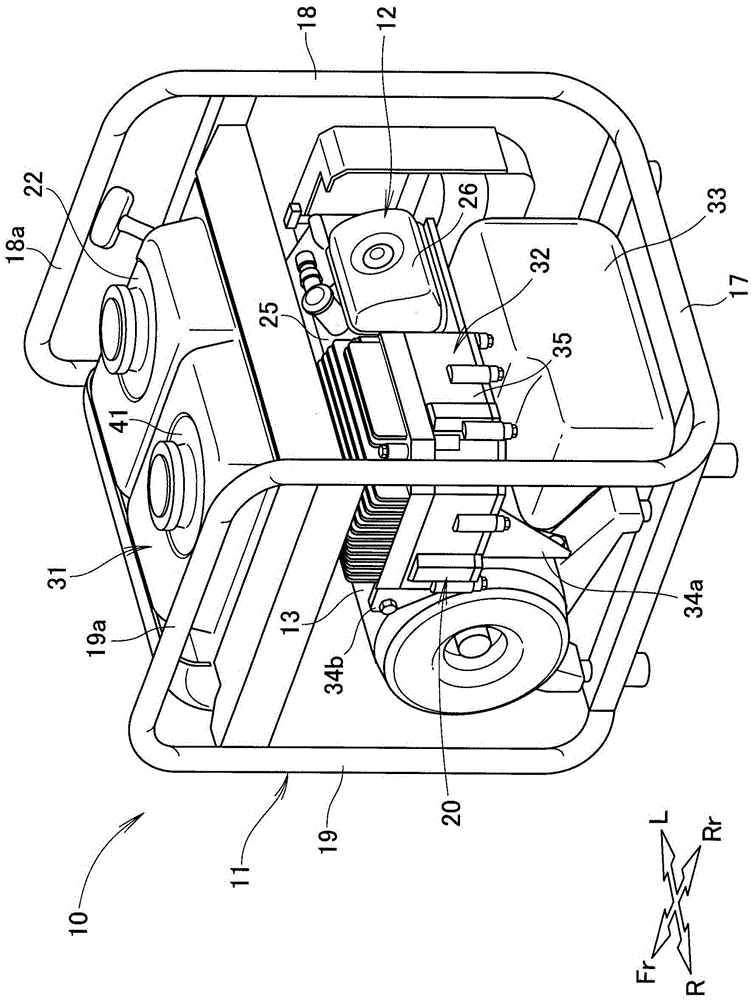

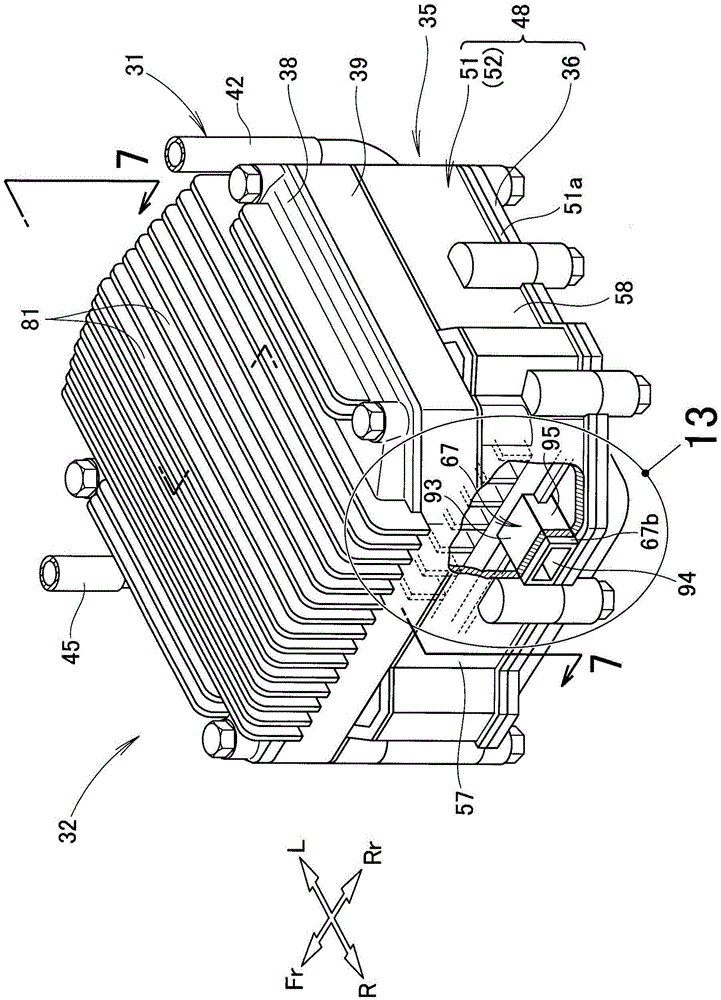

[0076] like figure 1 , figure 2 As shown, the engine-driven working machine 10 is provided with: a frame 11, which forms the outer frame of the engine-driven working machine 10; an engine 12, which is arranged at the front left lower part of the frame 11; generating device 20 disposed adjacent to generator 13 and engine 12 ; and operation panel 15 disposed in front of fuel tank 22 of engine 12 and raw water tank 41 of water generating device 20 .

[0077] The frame 11 has: a base 17 that supports the engine 12, the generator 13, and the clean water tank 33 of the water generator 20; a left frame 18 that is bent upward from the left end of the base 17; and a right frame 19 that It is bent upward from the right end of the base 17 . The engine-driven work machine 10 can be transported by holding the grip portion 18a of the left frame 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com